ASTM G154 UV Accelerated Aging Chamber Features and Benefits

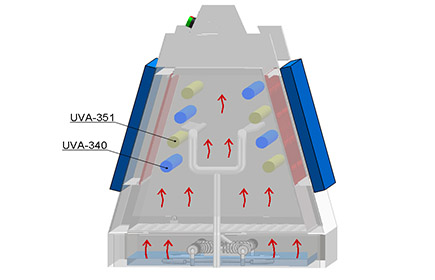

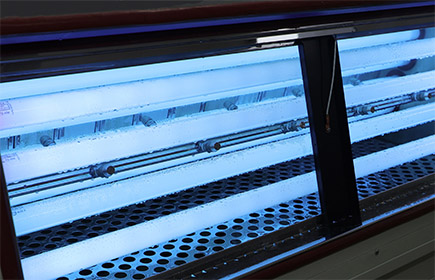

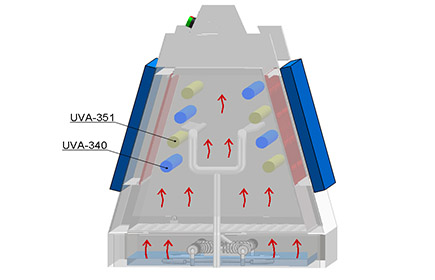

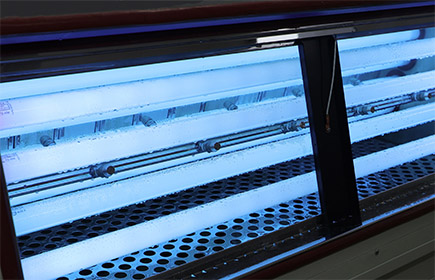

1. The UV accelerated aging chamber uses fluorescent ultraviolet lamps to simulate the ultraviolet part of sunlight: the UVA340 lamp simulates the shortwave ultraviolet (295-365 nm). The UVB313 lamp provides stronger ultraviolet radiation for accelerated material aging testing.

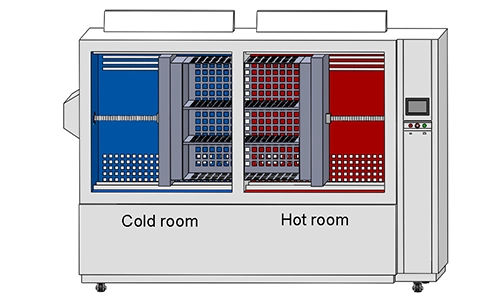

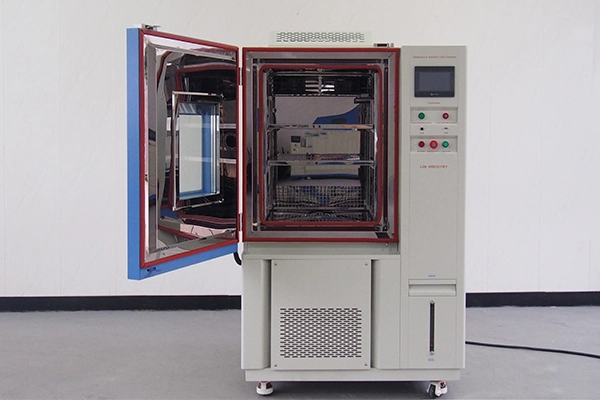

2. The ASTM G154 UV accelerated aging chamber can simulate high or low temperature environments to evaluate the aging behavior of materials under different temperature conditions, temperature control range: ambient to 90℃±2℃.

3. The workroom is made of SUS304 stainless steel, which is corrosion-resistant and easy to clean, and can work under long-term high humidity and high intensity ultraviolet light.

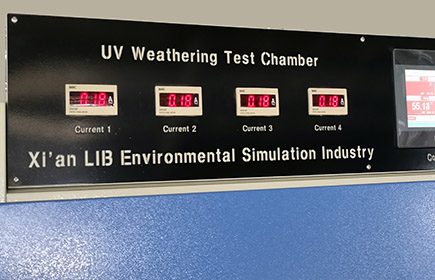

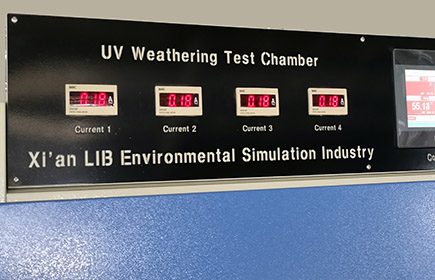

4. In the UV aging environment simulated, the temperature, spray and irradiation intensity can be controlled. The irradiation meter tracks the irradiation amount in real time and sends it back to the controller.

Specifications of ASTM G154 UV Accelerated Aging Chamber

Model | UV-SI-260 |

Internal Dimension (mm) | 450*1170*500 |

Overall Dimension (mm) | 610*1330*1470 |

Specimen Holder Size(mm) | 75*150 |

Specimen Capacity | 56 Pieces |

Irradiation Source | Fluorescent UV lamps (8) - 40 W |

Temperature Range | Ambient ~ 90 ℃ ±2℃ |

Black Panel Temperature (BPT) | 35 ~ 80 ℃ |

Humidity Range | ≥95% RH |

Bandwidth | 290 ~ 400nm |

Irradiance Control | 0.3~20 W/㎡ |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Distance of Specimen and lamp | 50mm |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water Supply System | Automatic water supply, Water purification system |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Details of ASTM G154 UV Accelerated Aging Chamber

|

|  |

| |

|  |

Including UVA-340, UVB-313, 8 lamp combinations, 40W. The ballast can stabilize the current and voltage of the lamp, ensure the stability of the output UV intensity, and the lamp life can be as large as 5000h. | Simulate the role of rainfall and dew in UV aging test, automatic water intake, equipped with water circulation and filtration system. 10 anti-rust nozzles, nozzle water of 0.3L /min. |

|  |

| The blackboard simulates the heating condition of the sample to reflect the actual temperature, BPT is 35 ~ 80 ℃. The irradiation meter ensures that the test ultraviolet intensity is compliant, and the irradiation intensity ranges from 0.3 to 20 W/㎡ |

OPTIONS: Standard sample holder, aluminum panels with rings |

Custom 3D sample holder |

|  |

Application of ASTM G154 UV Accelerated Aging Chamber

ASTM G154 UV Accelerated Aging test chamber is mainly used to evaluate the weather resistance of non-metallic materials (such as plastics, coatings, rubber, textiles and polymer materials) under simulated ultraviolet environment, and is widely used in the automotive, construction, aerospace and outdoor products industries.

Accelerate the aging process of materials through controlled UV light, temperature and humidity cycles to predict their resistance to UV degradation, color stability and mechanical properties in long-term use, providing key data support for product development, quality control and standard certification.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español