Features and Benefits of MFG Test Chamber

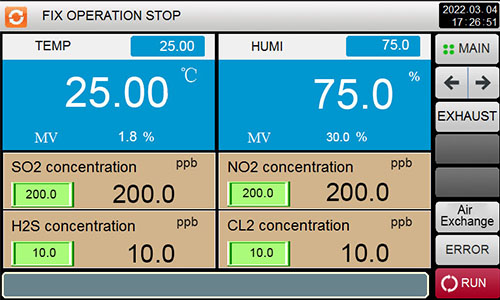

1. A variety of different gases, such as H2S,NO2,CL2,SO2,NH3,etc. are precisely mixed in a set proportion. High precision gas flow controller with control accuracy of parts per billion (ppb).

2. In addition to gas control, the temperature range can be controlled from 15 ° C to 100 ° C, and the humidity can be adjusted from 30% to 98%RH, which is broad and accurate temperature and humidity regulation to meet different test needs.

3. Equipped with high-precision gas flow controller, temperature sensor, humidity sensor, which can accurately control various parameters in the MFG test chamber to ensure the stability and accuracy of the test conditions.

4. The concave and convex design, silicone seal, electromagnetic lock are used to ensure the tightness of the test chamber during the test, prevent harmful gases from leaking.

Specifications of MFG Test Chamber

Model | GCM-100 | GCM-225 | GCM-500 |

Internal Dimensions (mm) | 400*500*500 | 500*600*750 | 700*800*900 |

Overall Dimensions (mm) | 1010*1050*1620 | 1110*1150*1860 | 1330*1350*2010 |

Interior Volume (L) | 100 | 225 | 500 |

Temperature Range | 15 ℃ ~ 80 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 30% ~ 98% RH |

Humidity Deviation | ±2.5% RH |

SO2 Concentration | 100 ~500 ppb± 20 ppb (Adjustable) |

H2S Concentration | 10 ~100 ppb ± 20 ppb (Adjustable) |

NO2 Concentration | 200 ppb ± 20 ppb (Adjustable) |

Cl2 concentration | 10 ~20 ppb ±5 ppb (Adjustable) |

Air Change Rate | 3~10times /h |

Cooling system | Mechanical compression refrigeration system |

Humidifier | External isolation, stainless steel surface evaporation humidifier |

Water Supply System | Water purification system, Automatic water supply |

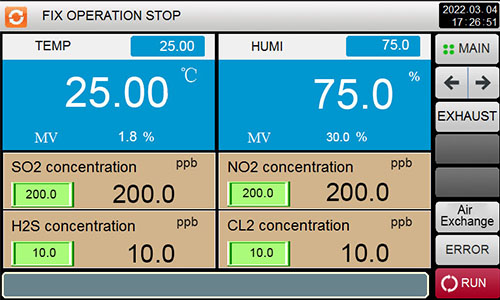

Controller | Programmable color LCD touch screen controller Ethernet connection, PC Link |

Gas Sensor | H2S/NO2/CL2/SO² gas sensor |

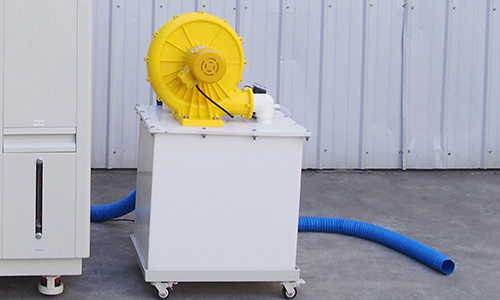

Air Circulation | Centrifugal wind fan |

Door Lock | Electromagnetic lock |

Gas Exhaust Device | Exhaust Unit |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection |

Interior material | SUS316 stainless steel +Glass fiber reinforced plastics |

Exterior material | Steel Plate with protective coating |

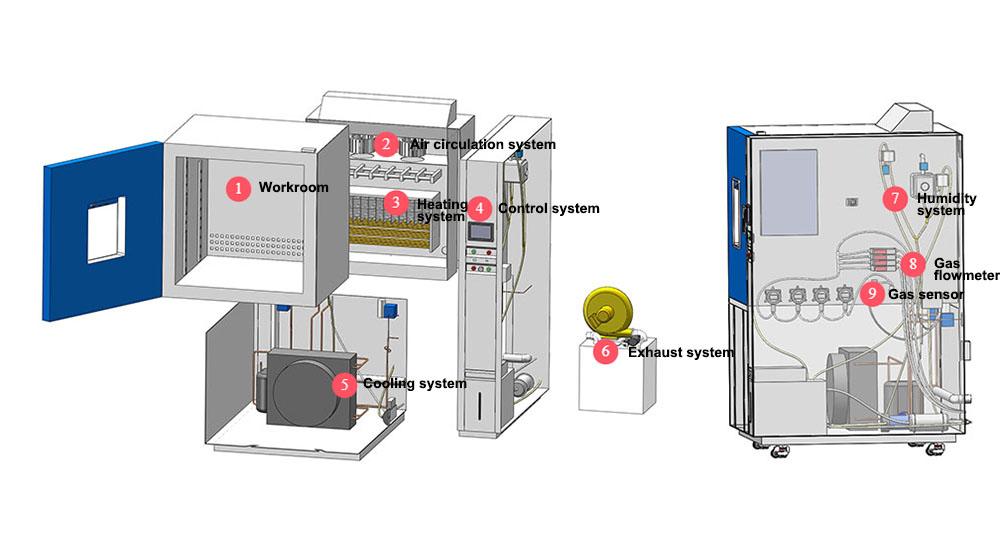

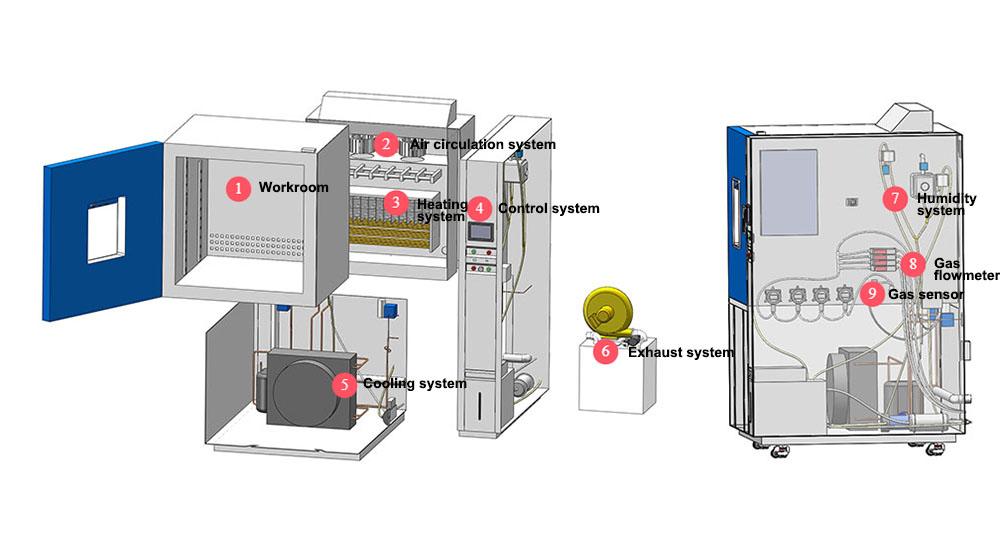

Configuration of MFG Test Chamber

①Workroom | The workroom’s SUS304 stainless steel material is covered with a layer of glass steel, which both prevents corrosion and enhances the robustness of the equipment. |  |

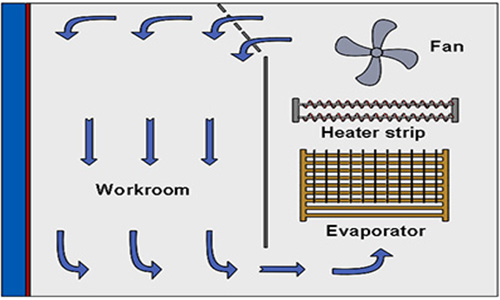

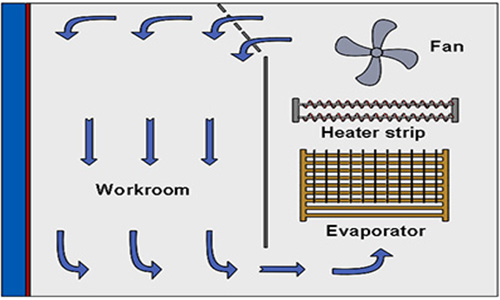

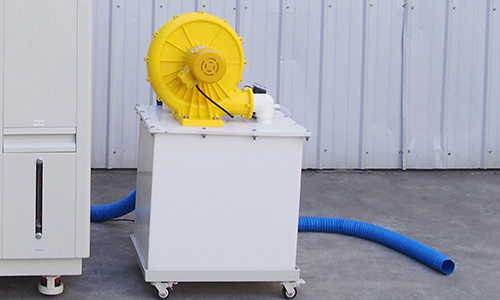

②Air circulation system | Composed of a centrifugal fan and a drive motor, the air in the test chamber is continuously circulated to ensure the uniform distribution of environmental parameters such as temperature, humidity and gas concentration in the chamber. |  |

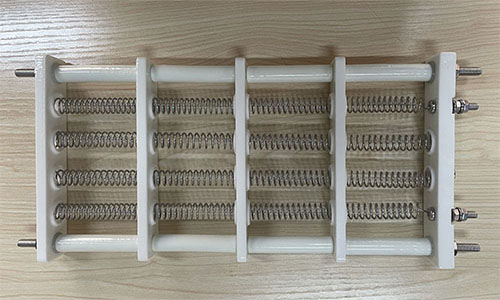

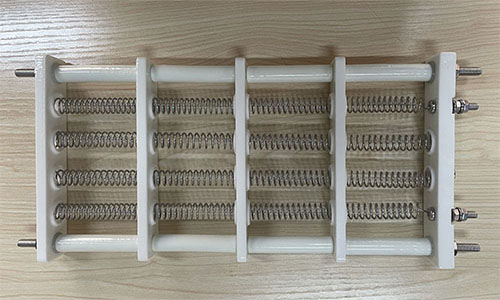

③Heating system | High power resistance wire, quickly raise the temperature in the test chamber. |  |

④Control system | PID accurately controls temperature, humidity, gas flow and other parameters, and also has monitoring, alarm and data recording functions. |  |

⑤Cooling system | Composed of compressor, condenser, throttle mechanism and evaporator. The temperature in the chamber is reduced by absorbing heat through the evaporation of the refrigerant. |  |

⑥Exhaust device | NAOH solution tank for diluting H2S/NO2/CL2/SO2, making the workplace clean and safe. Dilute H₂SO₄ tank can also be added to dilute alkaline gases.

|  |

⑦Humidity system | Steam humidification, quickly increase the humidity inside the chamber. |  |

⑧Gas flowmeter | Accurately measure and control the gas flow into the test chamber to ensure that the concentration of the gas inside the chamber reaches the set value required by the test. |  |

⑨Gas sensor | The high-precision gas sensor can monitor the concentration, type and other parameters of the gas in the chamber in real time, and feed the data back to the control system. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español