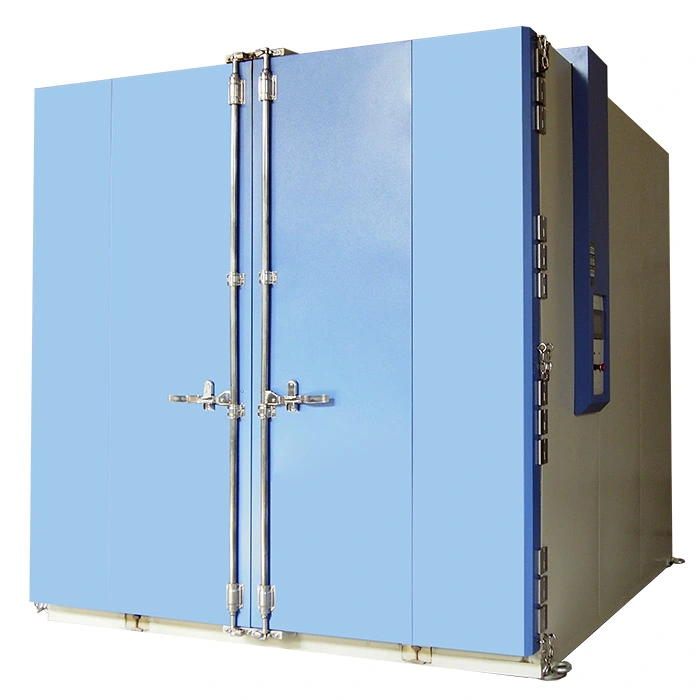

Mini Humidity Test Chamber Features and Benefits

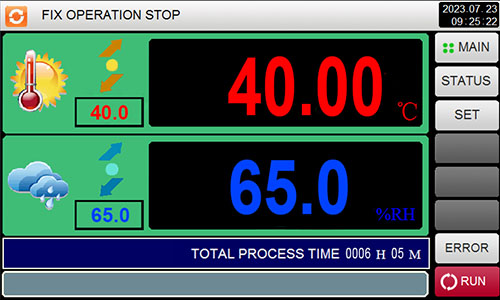

1. The temperature can reach a temperature range of -70℃ to 150℃ or even wider, and the temperature fluctuation is controlled at ±0.5℃. The humidity range is 20% to 98%RH, with a humidity deviation of ±2.5%RH, which can accurately simulate different temperature and humidity environments.

2. Efficient use of space, small size, in the laboratory can be flexibly adjusted position, does not take up too much space, convenient for operators to use, but also easy to use with other experimental equipment or instruments.

3. The high test efficiency and small internal space make the air circulation relatively fast, and can achieve the set temperature and humidity conditions in a short time, thus improving the test efficiency.

4. Mini humidity test chamber is ideal for temperature and humidity testing of small products, parts or materials, such as electronic components, small circuit boards, medical devices, cosmetics and other small items.

Specifications of Mini Humidity Test Chamber

Model | TH-50 | TH-80 |

Internal Dimension (mm) | 320*350*450 | 400*400*500 |

Overall Dimension (mm) | 820*1160*950 | 900*1210*1000 |

Interior Volume | 50L | 80L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

Cooling system | Mechanical compression refrigeration system |

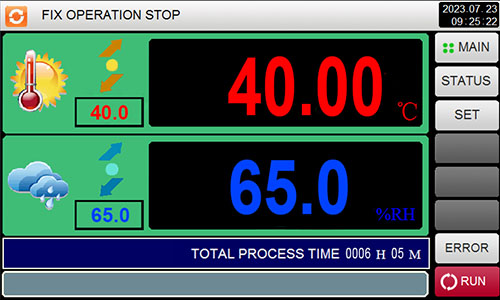

Controller | Programmable color LCD touch screen controller Ethernet connection |

Safety Device | Humidifier Dry-combustion protection; Over-temperature Protection; Over-current Protection; Refrigerant High-pressure protection; Water Shortage Protection; Earth leakage Protection |

Exterior Material | Steel Plate with protective coating |

Standard Configuration | 1 Cable hole (Φ 50,) with plug; 2 shelves |

Weight | 190kgs | 220kgs |

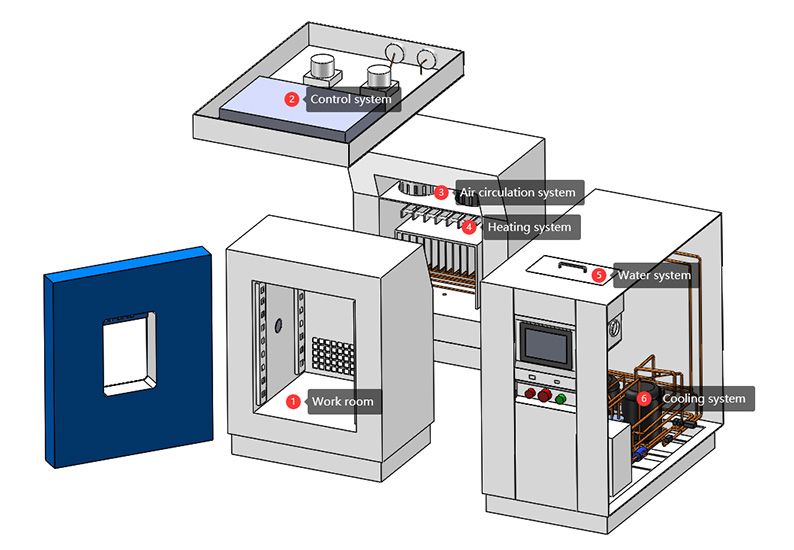

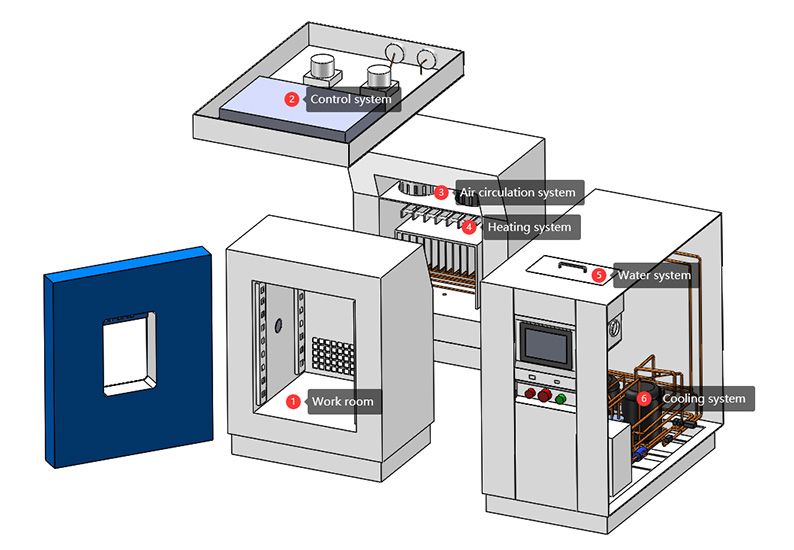

Configuration of Mini Humidity Test Chamber

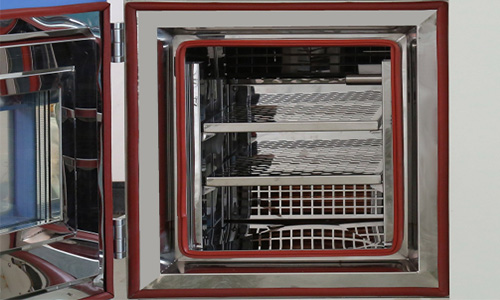

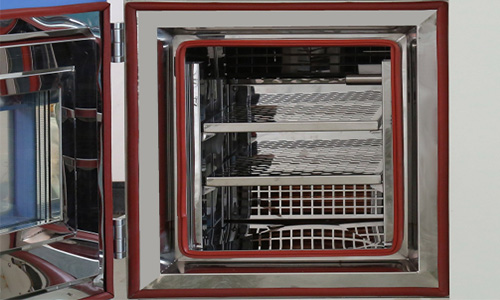

① Workroom | SUS 304 mirror plate is used in the workroom, which is corrosion-resistant and easy to clean.

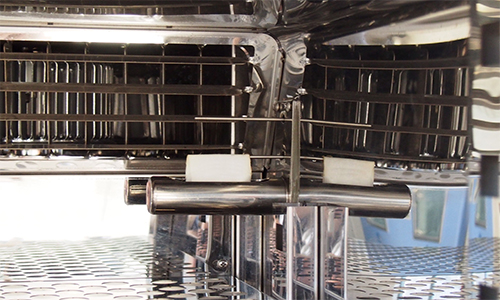

PT-100 Class A sensor, real-time accurate detection and display of temperature

changes at 0.001 degrees. A wet gauze and a real-time temperature, converted by temperature difference,showing real-time relative humidity. Standard two-layer perforated sample holder, bearing capacity 50KG. 50mm test hole on the left side of the workroom for specimen power supply.

|

|

② Control system | Touchscreen controller with PID algorithm to adjust heating, cooling and humidification, dehumidification and other working states. |  |

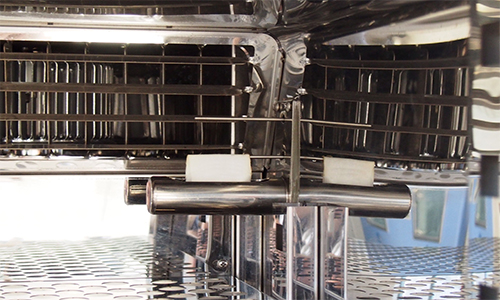

③ Air circulation system | multi-blade centrifugal wind turbine is used to provide power for the circulation of air in the chamber, so that the temperature and humidity distribution is more uniform. |  |

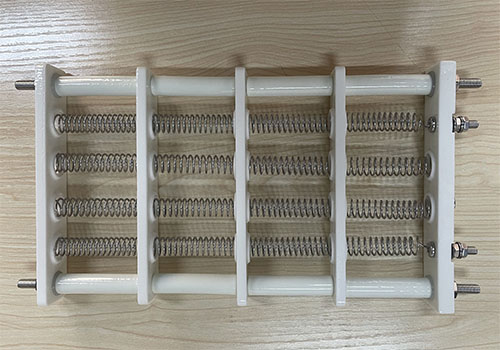

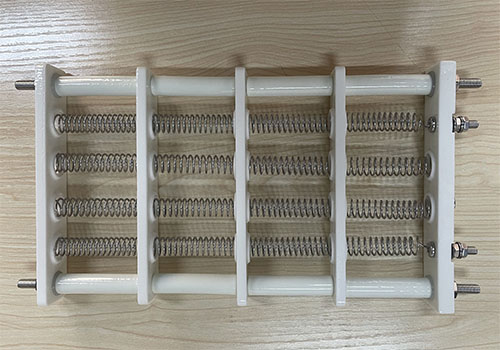

④ Heating system | The use of nickel-chromium alloy electric heating wire, heating efficiency, to provide the required temperature for the workroom. |  |

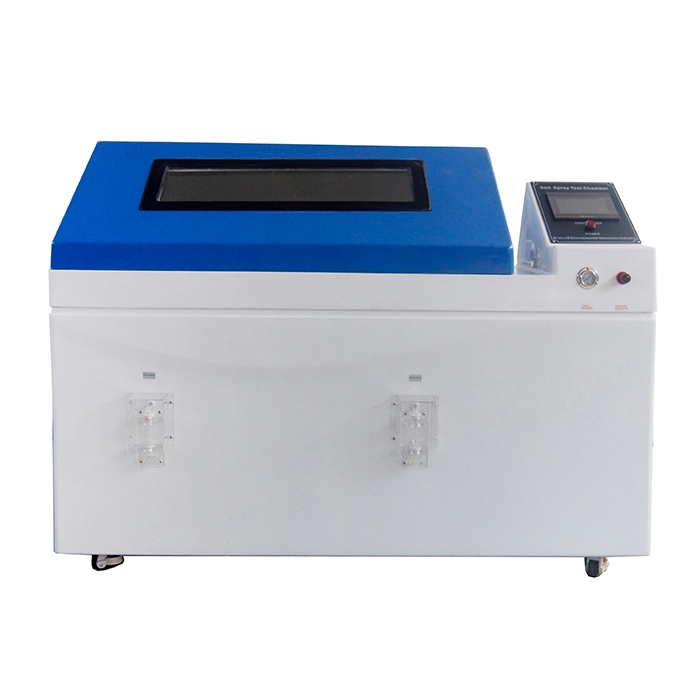

⑤ Water system | Steam humidification. According to the instructions of the controller, supply the appropriate amount of water vapor into the tank. |  |

⑥ Cooling system | Refrigeration system is composed of compressor, condenser, evaporator and refrigerant. Through refrigerant circulation and heat exchange, the temperature in the chamber is reduced. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español