Cycle Corrosion Tester Features and Benefits

1. A various corrosive environments, salt spray, humidity, condensation, temperature, with different cycle modes, such as the complex multi-step cycle of salt spray - high humidity - low humidity drying - static in SAE-J-2334 standard.

2. Cycle corrosion test device can precisely control environmental parameters, temperature can be accurate to ±0.5℃, humidity can be accurate to ±3%RH, salt spray concentration, spray amount, spray time can also be accurately controlled.

3. Through programming setting, each environment cycle switch and parameter adjustment can be completed automatically in order and time, without manual intervention, improving test efficiency and accuracy.

4. Long-term corrosion behavior and performance data of materials or products can be obtained in a relatively short time, speeding up the progress of research and development and quality inspection.

Cycle Corrosion Tester Specifications

Model | SC-010 | SC-016 | SC-020 |

Internal dimensions (mm) | 1300*1000*600 | 1600*900*720 | 2000*1000*800 |

Overall dimensions (mm) | 2000*1300*1600 | 2300*1300*1700 | 2700*1300*1900 |

Interior Volume (L) | 780 | 1280 | 1800 |

Temperature Range | +10 ℃ ~ +90 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 30% ~ 98% RH |

Humidity Deviation | + 2%, - 3% |

Salt Fog Deposition | 1~2ml / 80cm2 · h |

Cooling system | Mechanical compression refrigeration system |

Humidifier | External isolation, stainless steel surface evaporation humidifier |

Water supply system | Water purification system |

Air Preheating | Saturated air barrel (31Liter) |

Spraying System | Atomizer tower and Spray nozzles |

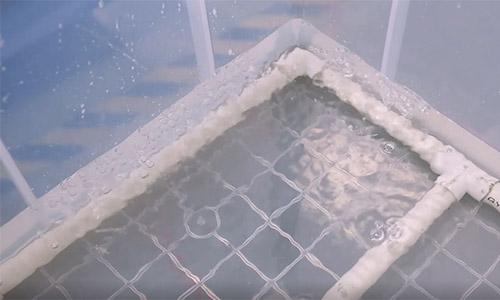

Salt Fog Collected | Fog collector and fog measure cylinder |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Air Circulation | Centrifugal wind fan |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection |

Material | Glass fiber reinforced plastics |

Standard Configuration | 8 round bars |

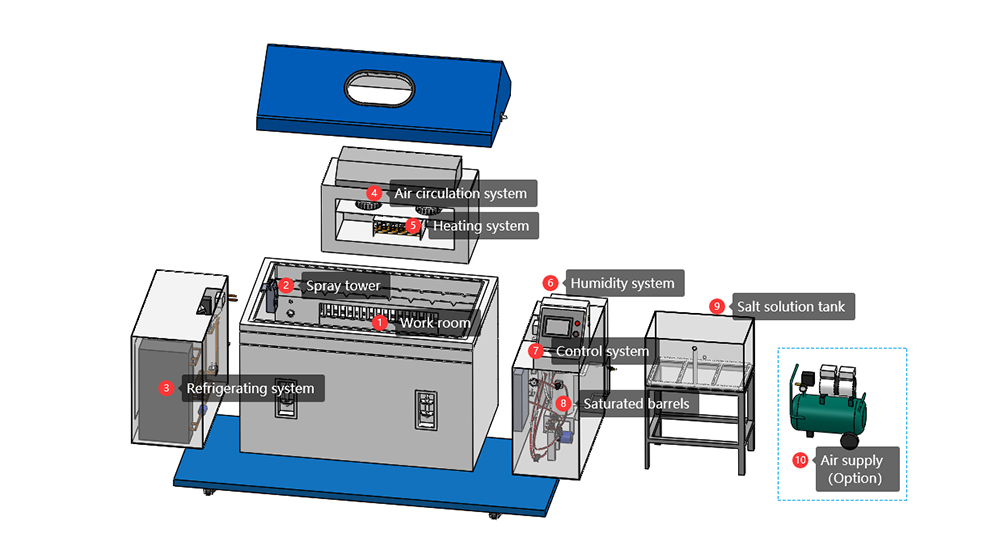

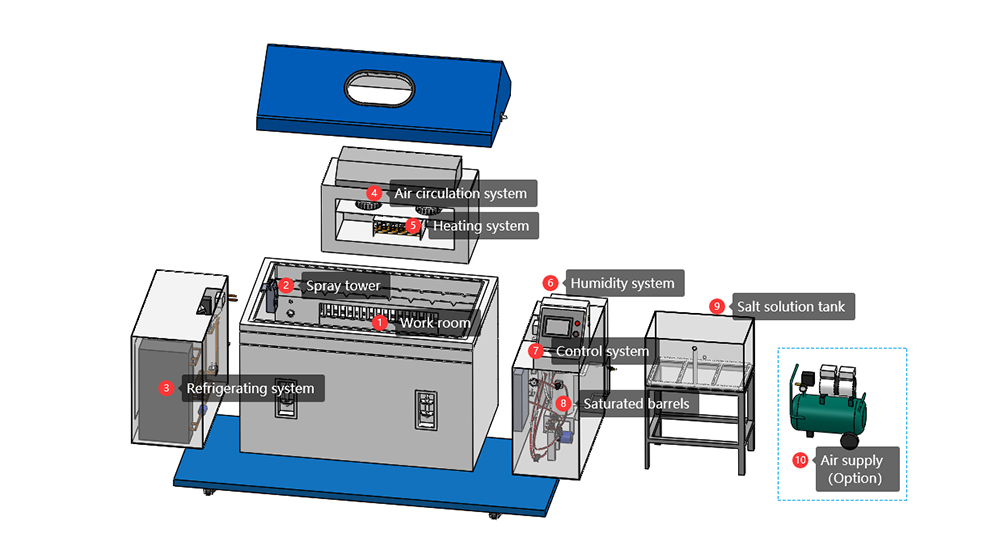

Configuration of Cycle Corrosion Tester

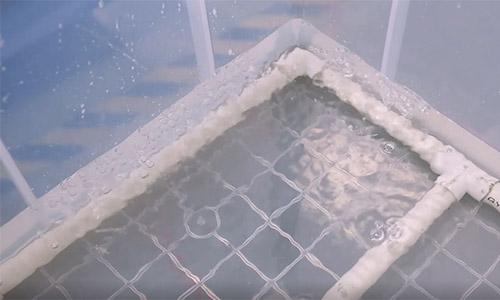

①Workroom | Made of corrosion-resistant materials, glass fiber reinforced plastic, with good sealing, to prevent salt spray, water vapor and other leakage.

|  |

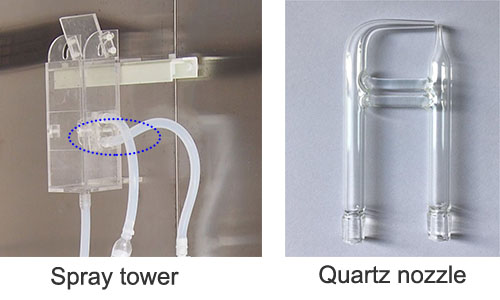

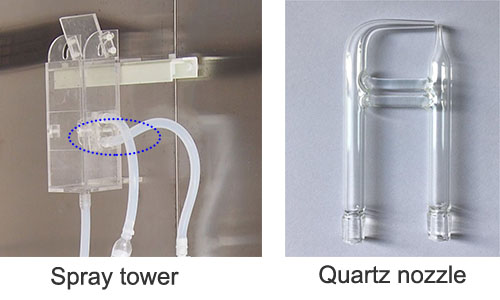

②Spray tower | Including a nozzle and a salt spray disperser, the nozzle is made of tempered glass, and the salt spray disperser can make the atomization degree more uniform. The brine is atomized and sprayed into the workroom to form a salt spray environment.

|  |

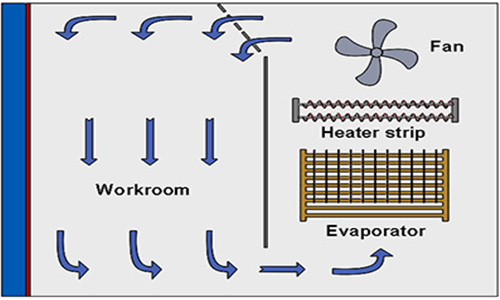

③Refrigerating system | Composed of refrigeration compressor, condenser and evaporator, and accurately controls the temperature and humidity in the chamber. |  |

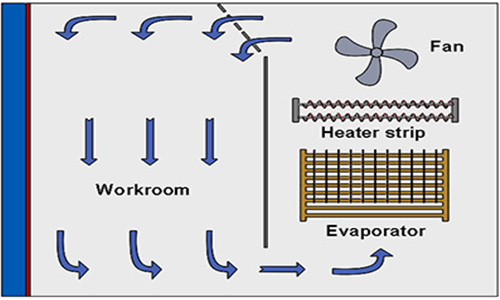

④Air circulation system | Keep the air circulation in the workroom, so that the temperature and humidity in the workroom and the salt spray remain uniform, and improve the accuracy of the detection. |  |

⑤Heating system | Composed of a heater and a temperature sensor. By heating, the cyclic corrosion tester can reach the set drying temperature, and simulate the effect of drying environment on sample corrosion.

|  |

⑥Humidity system | By heating the water to produce steam, and then the steam into the workroom, adjust the humidity in the tester. |  |

⑦Control system | Realize the function of parameter setting, operation control, data monitoring, test cycle procedures setting and recording of each system. |  |

⑧Saturated barrel | To provide a stable saturated air for the test, to ensure the formation and uniform distribution of salt spray. It is equipped with temperature control system and water level monitoring device.

|

|

⑨Salt solution tank | The prepared brine solution is stored and the stirring device mixes the brine solution evenly. |  |

⑩Air supply(option) | Provide compressed air for the test, atomize the brine solution to form a salt spray, and evenly spray the salt spray on the surface of the test sample. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español