Small Humidity Test Chamber Features and Benefits

1. The volume of the small humidity test chamber is convenient for use and placement in places with limited space. At the same time, it is also very suitable for the detection of small test parts, and its operation requires relatively less energy consumption, which is an efficient and energy-saving test chamber.

2. This mini humidity test chamber is equipped with high-precision temperature and humidity sensor, accurately control the temperature and humidity. A wet gauze and a real-time temperature with 0.001 degrees accuracy, converted by temperature difference, showing real-time relative humidity.

3. The test hole located on the side of workroom can be used to energize the test piece to more truly simulate the operating state of the test piece's ability to adapt to humidity.

4. A variety of test modes can be set at LIB Industry, such as constant temperature and humidity test, alternating temperature and humidity test.

Specifications of Small Humidity Test Chamber

Model | TH-50 | TH-80 |

Internal Dimension (mm) | 320*350*450 | 400*400*500 |

Overall Dimension (mm) | 820*1160*950 | 900*1210*1000 |

Interior Volume | 50L | 80L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

Cooling system | Mechanical compression refrigeration system |

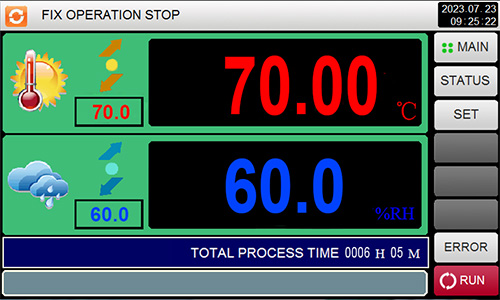

Controller | Programmable color LCD touch screen controller Ethernet connection |

Safety Device | Humidifier Dry-combustion protection; Over-temperature Protection; Over-current Protection; Refrigerant High-pressure protection; Water Shortage Protection; Earth leakage Protection |

Exterior Material | Steel Plate with protective coating |

Standard Configuration | 1 Cable hole (Φ 50,) with plug; 2 shelves |

Weight | 190kgs | 220kgs |

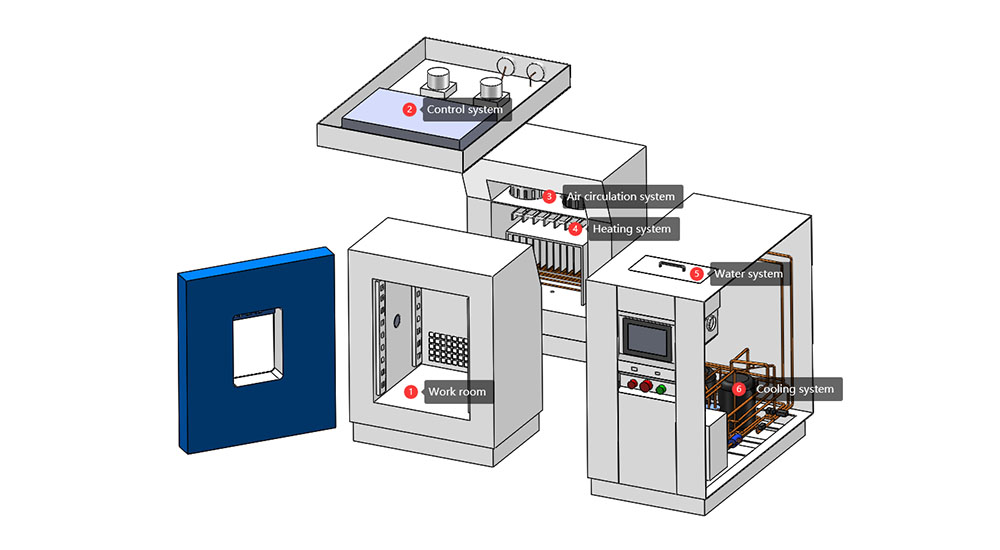

Configuration of Small Humidity Test Chamber

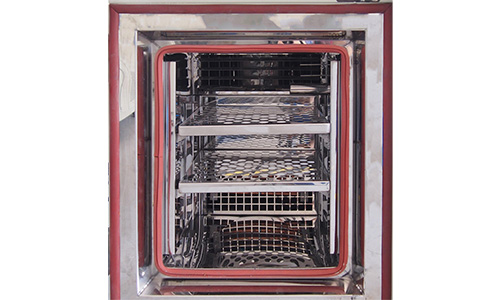

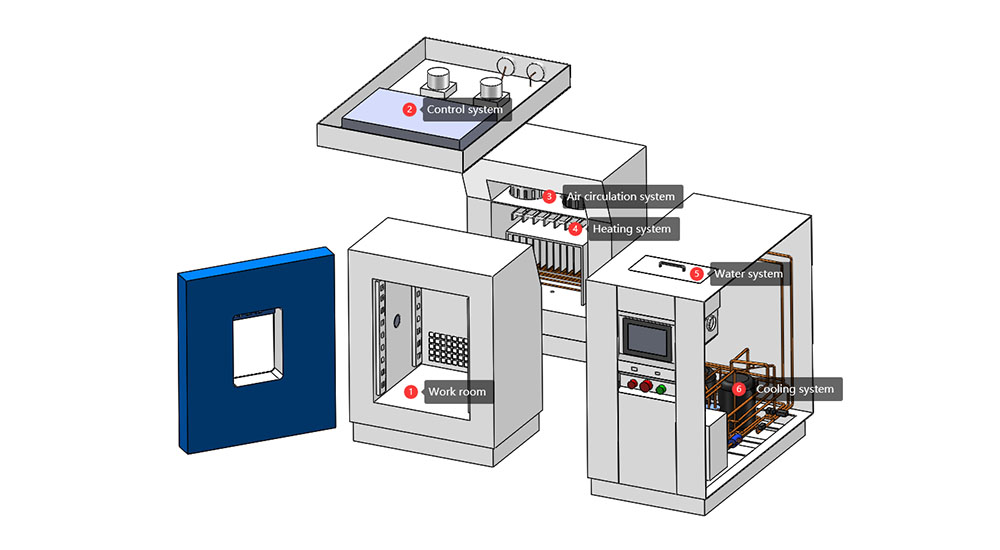

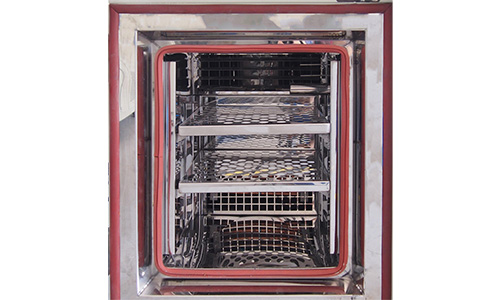

①Workroom | The standard double-layer sample shelf can bear 50 kg per layer. Test parts in the workroom can be energized through cable hole. It is equipped with temperature and humidity probes for real-time and precise feedback. |  |

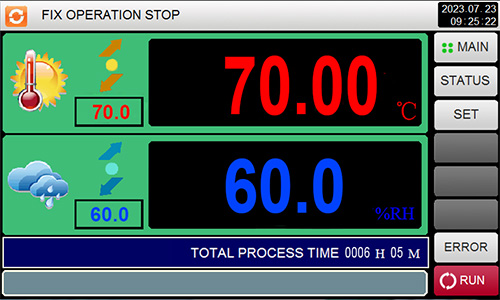

②Control system | Touchable PID screen controller. Settings like temperature and humidity test time and cycle times can be made on the controller. Data can be downloaded as well. |  |

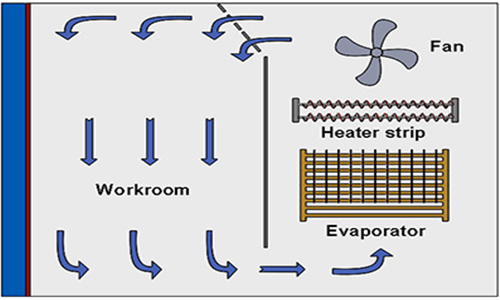

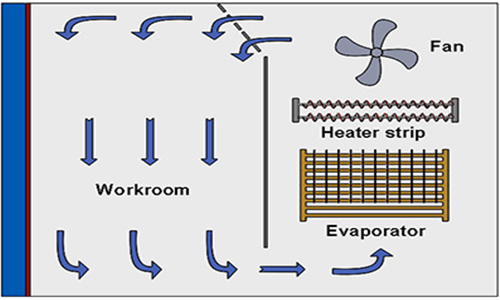

③Air circulation system | The core part is the fan positioned above the back of the workroom. Air is discharged from the top and returned from the bottom, ensuring even distribution of temperature and humidity. |  |

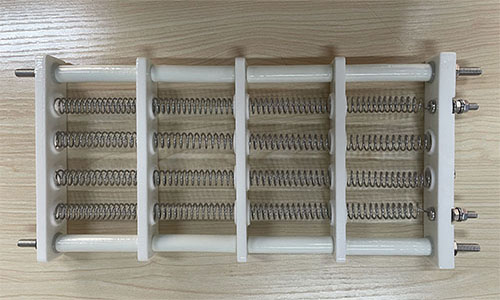

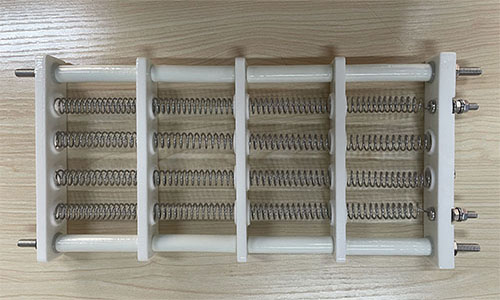

④Heating system | Heating system adopts nichrome heater having high-efficiency heating speed. |  |

⑤Water system | Water is heated to boiling via the steam generator to produce water vapor. It has high humidification efficiency and precise humidity control. |  |

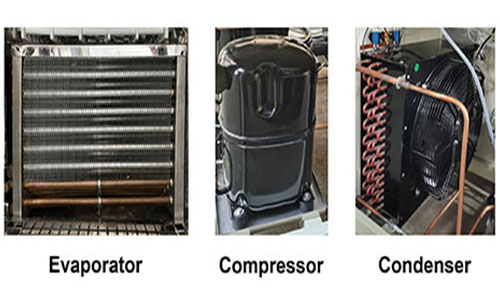

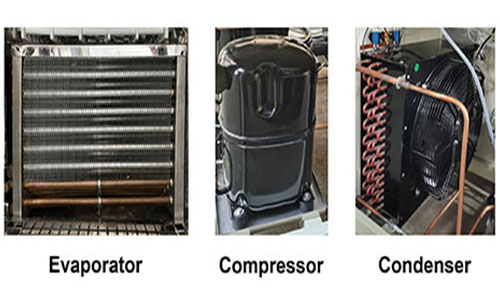

⑥Cooling system | The refrigeration system consists of compressor, condenser, throttling element and evaporator. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español