As a specialized piece of testing equipment, the salt fog machine plays a vital role in assessing the corrosion resistance of a material or product. By simulating high salinity environments, the salt fog machine can provide us with accurate data on the corrosion resistance of materials, helping companies and R&D organisations to make more informed decisions. In this article, we will delve into how the salt fog machine can help assess corrosion resistance, and it is divided into the following four sub-headings for elaboration.

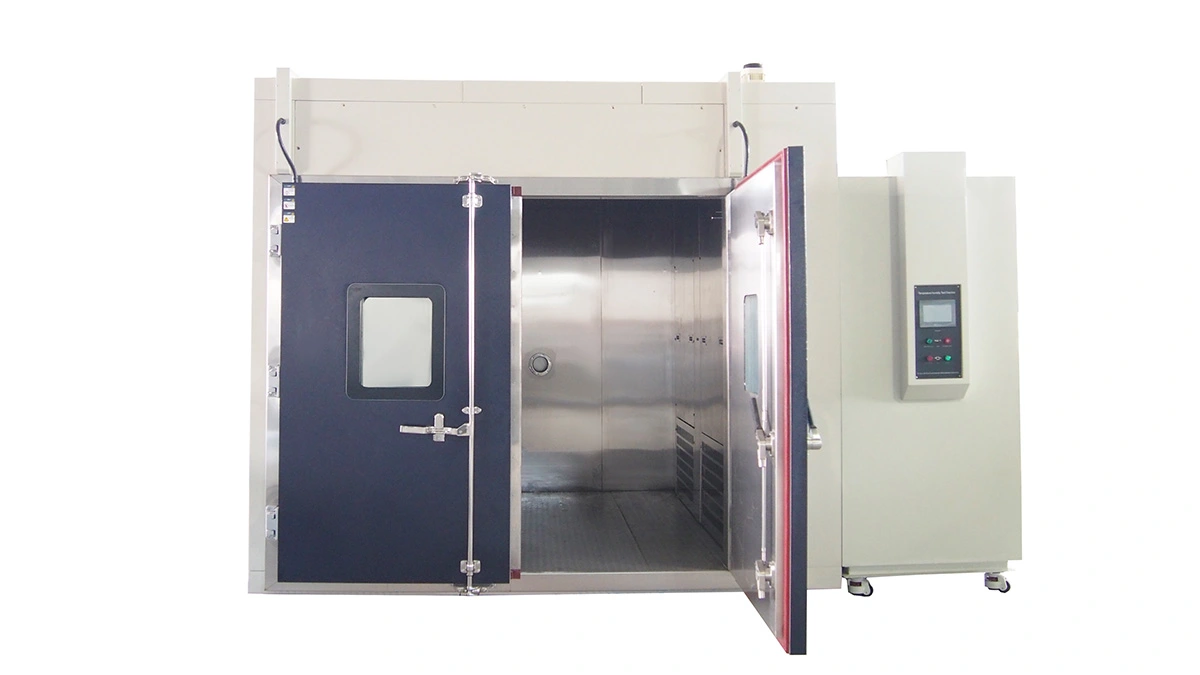

As for salt spray chamber working principle, the salt fog machine works by spraying atomized gas containing a certain concentration of sodium chloride solution, simulating the ocean, coastal areas, and other high salinity environments, subjecting the tested material or product to continuous, stable corrosion. This simulated environment can closely replicate the corrosion conditions in actual usage scenarios, making the test results more valuable for reference.

In the testing process, the salt fog machine will strictly control the temperature, humidity, salt fog concentration, and other parameters in the test chamber to ensure the consistency and repeatability of the test environment. At the same time, the salt fog machine can also be customized according to different test cycles and spray methods to meet the test requirements of different materials and products.

The salt fog machine has a wide range of applications in corrosion resistance assessment, involving metal materials, coatings, plastics, electronic products, and other fields. By placing the test sample in the salt fog machine for a certain period, we can observe and analyze the sample's corrosion in a simulated high salinity environment, to assess its corrosion resistance.

In practical application, the salt fog machine can also be used in conjunction with other testing equipment, such as electrochemical workstations, metallurgical microscopes, etc., to conduct more in-depth research and analysis of the corrosion behaviour of the sample. Furthermore, the salt fog machine can be used to compare the corrosion resistance of different materials or coatings, providing robust support for product design and material selection.

After the completion of the salt fog machine test, we need to interpret and apply the test results. Firstly, by observing and analyzing the sample's corrosion, we can determine the corrosion resistance level of the sample in the simulated high salinity environment. This helps us to understand the corrosion resistance performance of the sample in actual usage scenarios and provides guidance for the use and maintenance of the product.

Secondly, we can also integrate the salt fog machine test results with other test data for comprehensive analysis and comparison. For example, comparing electrochemical test data, and metallurgical analysis data with the salt fog machine test results to obtain a more comprehensive understanding of the corrosion behaviour and mechanism of the material. This supports in-depth studies of material corrosion resistance, providing strong support for product development and improvement.

With the continuous progress of science and technology and the ongoing development in the industrial field, the application of the salt fog machine in corrosion resistance assessment will become increasingly extensive. In the future, the salt fog machine will evolve towards being more intelligent, accurate, and environmentally friendly.

Firstly, intelligence will become an important development trend for the salt fog machine. Through the introduction of advanced sensors and control systems, the salt fog machine will be able to achieve more accurate environmental control and parameter settings, improving the accuracy and reliability of the test. Intelligent salt fog machines will also have data analysis and processing capabilities, automatically recording and analyzing test results, to provide users with more convenient and efficient services.

Secondly, precision is also a significant direction for the development of the salt fog machine. With deeper studies into the corrosion behaviour of materials, there is a need to simulate corrosion conditions in actual usage scenarios more accurately. Therefore, the salt fog machine will continue to improve the precision and stability of its simulation environment to better meet users' testing needs.

Finally, environmental protection is also an important trend for the future development of the salt fog machine. In the testing process, the salt fog machine will produce a certain amount of waste liquid and exhaust gas, causing some environmental impact. Hence, future salt fog machines will focus more on environmental protection design, using more environmentally friendly reagents and emissions treatment to minimize environmental pollution.

In summary, as an important tool for assessing corrosion resistance, the salt fog machine will play an increasingly significant role in the future. With the advancement of science and technology and the expansion of applications, the salt fog machine will continue to evolve and improve, providing robust support for the development of industrial sectors.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español