In many fields such as materials science, coatings, plastics, rubber, automotive industry, xenon aging test chamber is an important equipment for evaluating the weather resistance and durability of materials. With the continuous development of technology, there are many types of xenon aging test chambers on the market. This article will focus on the analysis of two mainstream models of xenon aging test chamber, discuss their similarities and differences, to help users better understand and choose the equipment suitable for their needs.

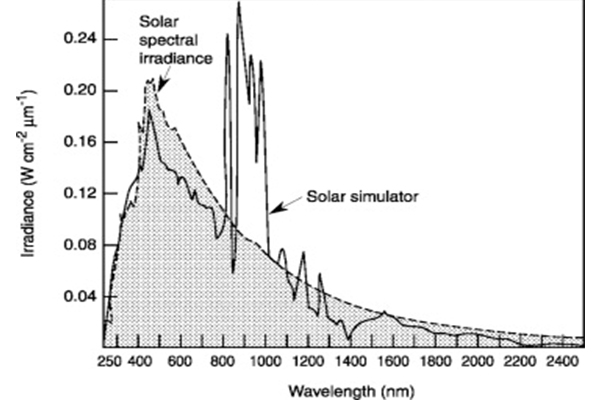

The xenon aging test chamber simulates solar radiation, temperature, humidity and other factors in the natural environment, and evaluates the performance changes of materials in the course of long-term use by accelerating aging. Its working principle is to use xenon lamps to simulate the radiation of the sunlight spectrum, to irradiate the sample, while controlling the temperature and humidity in the chamber to simulate different climatic conditions.

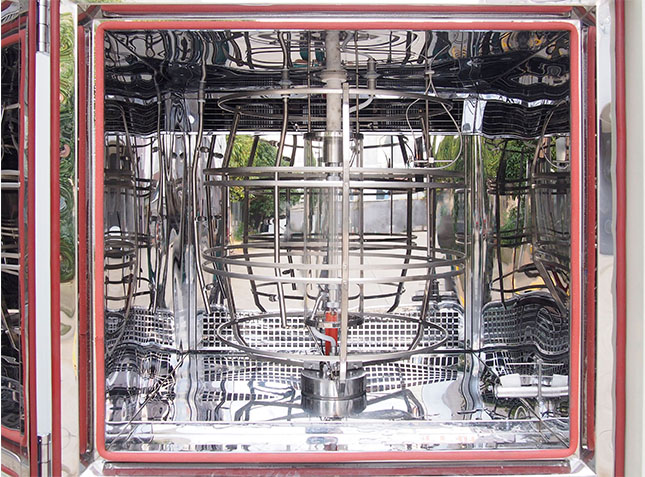

1. Water-cooled xenon aging test chamber

The water-cooled xenon aging test chamber usually uses high-power xenon lamp tube, and the heat generated by the lamp tube is taken away by the circulating water cooling system. This type of equipment has high irradiation intensity and stability, and can meet the requirements of high test accuracy application scenarios.

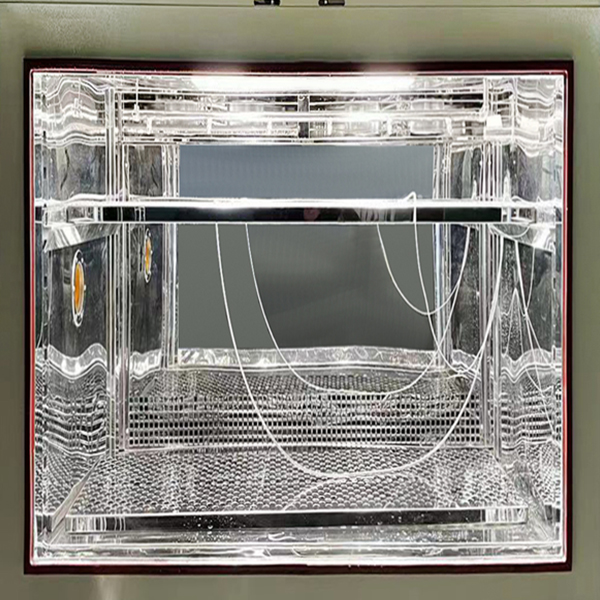

2. Air-cooled xenon aging test chamber

The air-cooled xenon aging test chamber cools the lamp tube and the cabinet by means of fan forced air cooling. Compared with the water-cooled type, its structure is relatively simple, convenient installation and maintenance.

1. Simulate the sunlight spectrum

Both water-cooled and air-cooled xenon aging test chambers are dedicated to simulating the true sunlight spectrum, including ultraviolet, visible and infrared parts. This allows them to reproduce, in a laboratory setting, more accurately the effects of photoageing on materials exposed outdoors.

2. Temperature and humidity control

Both models have precise temperature and humidity control. Specific temperature and humidity conditions can be set according to different test standards and sample requirements to simulate various climatic environments.

3. Data collection and recording

All are equipped with advanced data acquisition system, which can monitor and record various parameters in the test process in real time, such as irradiation intensity, temperature, humidity, sample performance changes, etc. These data are essential for evaluating the aging properties of materials and analyzing test results.

1. Cooling method

As mentioned earlier, the water-cooled type relies on a circulating water cooling system, while the air-cooled type relies on fan forced air cooling. The water-cooled type has a more significant cooling effect and can support the operation of higher power xenon lamps, thus providing stronger irradiation intensity.

However, the installation and maintenance of the water cooling system is relatively complex, and the quality of the water and the operation of the circulation system need to be checked regularly. The air-cooled type does not need a complex water cooling system, but its cooling capacity is relatively weak, and it is suitable for tests where the irradiation intensity is not particularly high. Air-cooled xenon lamp tubes are mounted side by side at the top of the chamber and are protected by circulating air. Water cooled xenon lamp 1 lamp tube installed in the center of the chamber, using circulating water to protect the lamp tube.

2. Irradiation intensity

Due to the difference in cooling methods, the water-cooled xenon aging test chamber is often able to provide higher irradiation intensity, which is suitable for testing where the weather resistance of materials is extremely demanding, such as aerospace, automotive exterior decoration and other fields. The irradiation intensity of air-cooled type is relatively low, and it is more suitable for some general material aging tests.

Air-cooled xenon aging test chamber (plate type) : radiation intensity :≤300W/㎡, relatively suitable for "indoor products"; Water-cooled xenon aging test chamber (rotary drum xenon lamp) : radiation intensity :≤1200W/㎡, relatively suitable for "outdoor products".

3. Sample frame structure

The sample shelf of the air-cooled argon lamp aging test chamber is pallet type, and the height can be adjusted manually. The distance between the sample shelf and the lamp is 230~280mm, and there is no requirement for the shape of the tested product, as long as it can be placed on the sample tray.

The sample shelf of the water-cooled argon lamp aging test chamber is a rotating drum type rotating disk, which can be rotated 360°, but the shape of the product to be tested is required, which must be thin, the standard template size is 75mm×150mm, and is hung on the rotating disk for test.

4. Maintenance costs

Water-cooled maintenance costs are higher, including water replacement, water quality treatment, cooling system maintenance, etc. The maintenance of air-cooled type is mainly concentrated on the fan, lamp and other components, which is relatively simple and economical.

When choosing a water-cooled or air-cooled xenon aging test chamber, the user should consider the following factors:

1. Test requirements

If the test standard or product application environment has high requirements for irradiation intensity and test accuracy, water-cooled type may be a better choice. If the test requirements are relatively loose, the air-cooled type can meet the needs.

2. Budget

With a sufficient budget, water-cooled models can provide superior performance and more accurate test results. When the budget is limited, air-cooled is a more cost-effective option.

3. Laboratory space

The laboratory space is large enough to accommodate large equipment and there are conditions to install water cooling systems, water cooling is feasible. If space is limited, air-cooled compact design is more suitable.

4. Maintenance capability

If the user has strong equipment maintenance ability and technical support, the water-cooled complex maintenance work can be dealt with. Otherwise, simple air-cooled maintenance may be more appropriate.

In summary, the water-cooled and air-cooled xenon aging test chambers are similar in working principle, but there are differences in cooling methods, irradiation intensity, equipment volume, price and maintenance costs. Users should be based on their own testing needs, budget, laboratory conditions and other factors in the selection of comprehensive consideration, in order to choose the most suitable equipment.