Features and Benefits of IPX4 Test Equipment

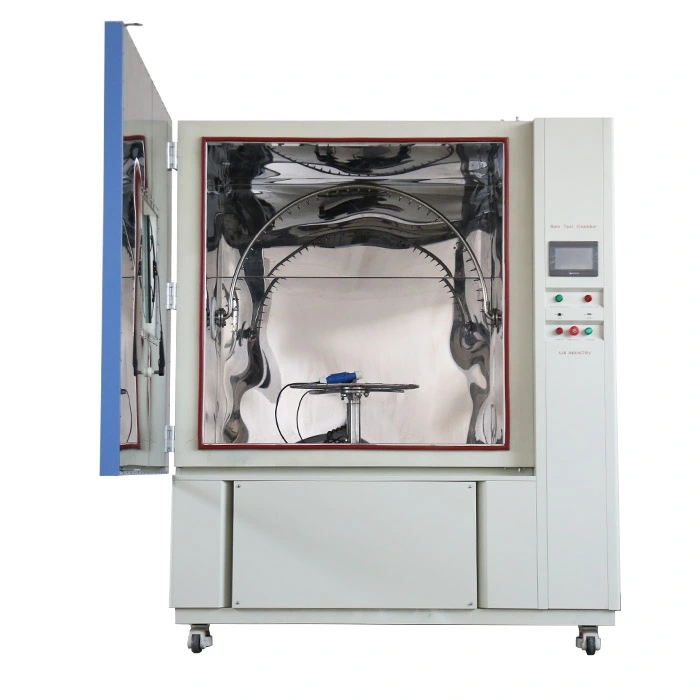

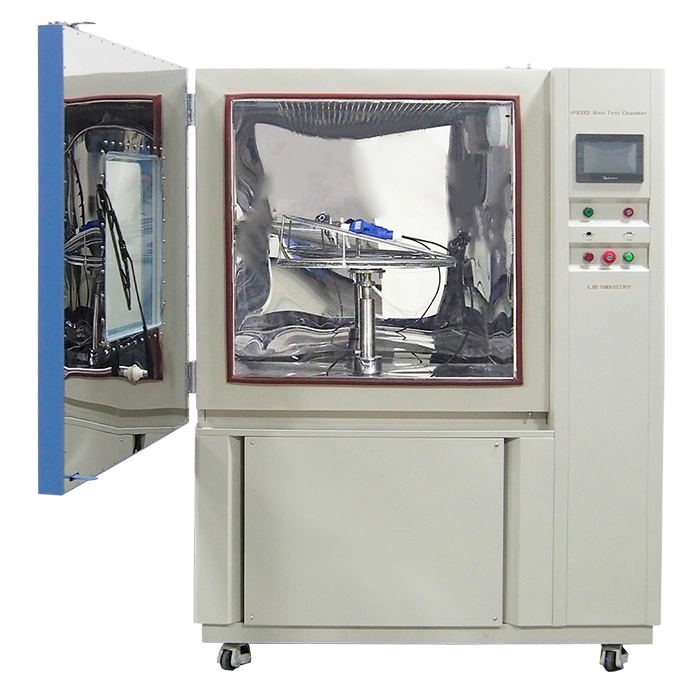

1. The shell is A3 steel plate, the surface is sprayed and painted, beautiful and water vapor resistant; The inner workroom and turntable are made of SUS304 stainless steel plate, which is not easy to rust.

2. The oscillating tube radius can be selected, 400mm, 600mm, etc. The drip aperture has ø0.4mm, ø0.8mm optional, the nozzle angle is 180°, and the oscillating angle is 350°and other parameters can be flexibly adjusted according to the specific test needs.

3. The equipment comes with water tank, can realize automatic circulation of water, water, high degree of automation, easy operation, can quickly complete the test process, improve the test efficiency.

4. Widely used in electronic products, communication equipment, household appliances, auto parts, lamps and other products waterproof performance test, to meet the testing needs of different industries and fields.

Specifications of IPX4 Test Equipment

Model | R-800C | R-1200C |

Internal Dimensions (mm) | 900*950*950 | 1300*1350*1370 |

Overall Dimensions (mm) | 1180*1420*1920 | 1540*1820*2200 |

Useful Volume (L) | 810 | 2400 |

Oscillating Tube Radius | 400mm | 600mm |

Spraying Hole Diameter | φ0.4mm |

Hole Spacing | 50 mm |

Swing angle of Oscillating Tube | 0 ~ ±180° (Adjustable) |

Turntable Rotation Speed | 1r/min (Adjustable speed) |

Water Pressure Control | Flow meter |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water supply system | Water tank, booster pump, Automatic water supply, Water purification system |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Observation Window | Double layer insulating glass with wiper |

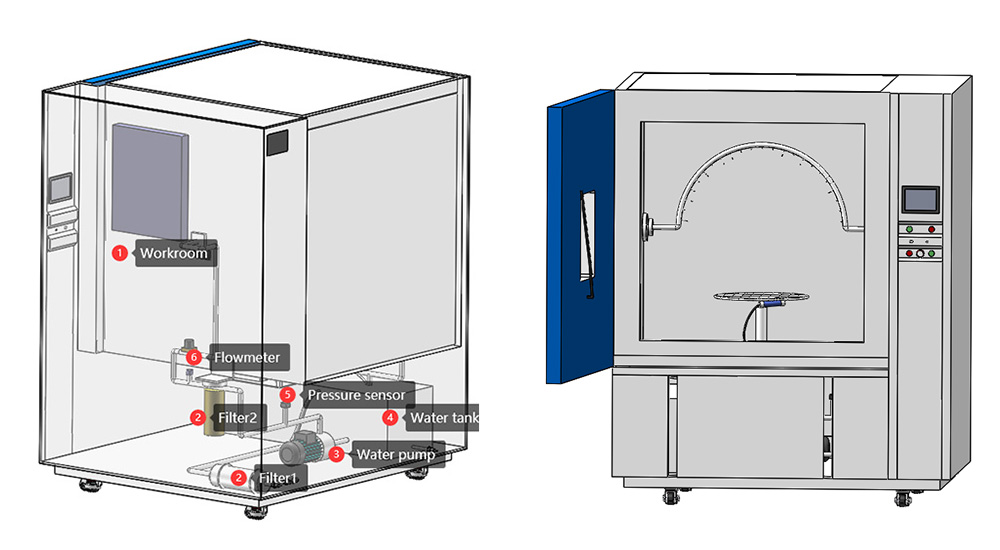

Configuration of IPX4 Test Equipment

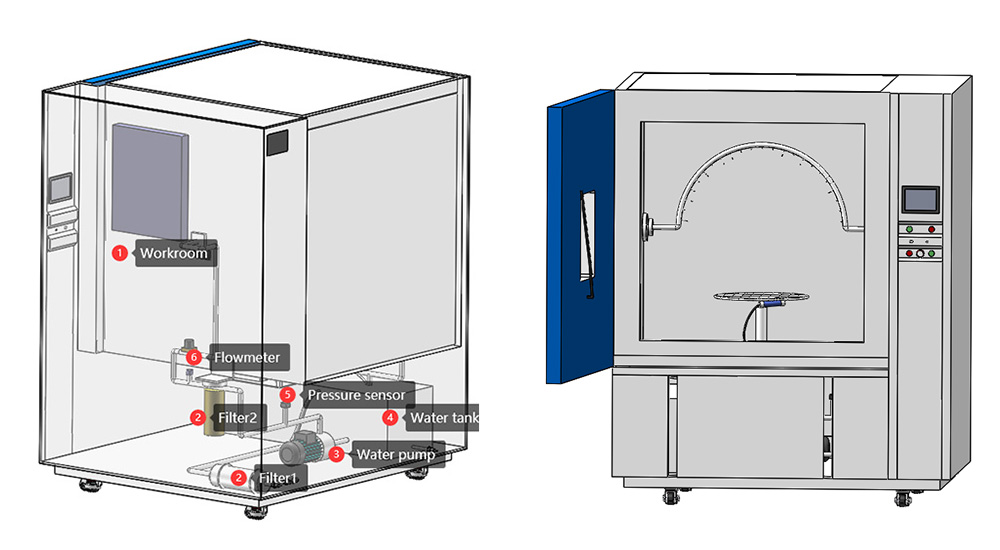

①Workroom | The inner workroom and turntable are made of SUS304 stainless steel plate to prevent rust. The oscillating tube radius specifications are R200mm, R400mm, R600mm, etc. The inner diameter of the pendulum tube is φ15mm to ensure stable water flow through. The size of the blowhole is 0.4mm in diameter, and a 0.8mm blowhole can be selected. The angle of the spray nozzle is 120° during IPX3 test and 180° during IPX4 test. The nozzle adopts a detachable structure for easy cleaning or replacement, and part of the nozzle is also embedded with the ball for easy adjustment of the spray angle. Equipped with transparent window and LED lighting for easy observation of test conditions.

|

|

② Filter | The standard high-precision filter can effectively filter the 0.03mm impurities , prevent it from blocking the blowhole, and the filter element is changed once a year.

|

|

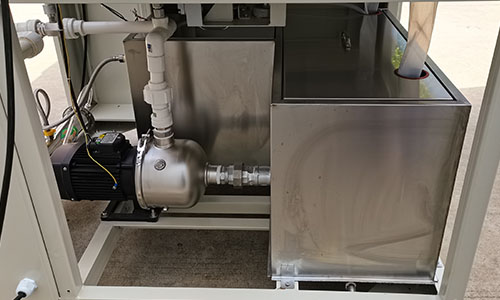

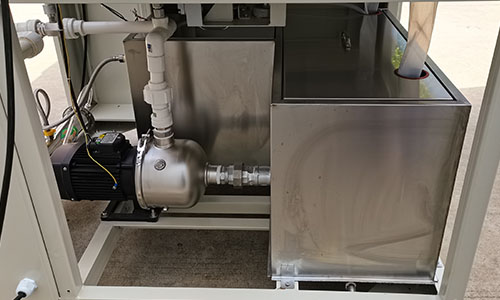

③ Water tank | It adopts the method of circulating water, equipped with liquid level sensor, which can automatically control the water intake, and has low water level alarm detection and protection system. |  |

④ Water pump | A key component to provide water jet power, the pump can achieve a flow rate of 2.6l/min±5 during IPX4 tests. With automatic water control function.

|  |

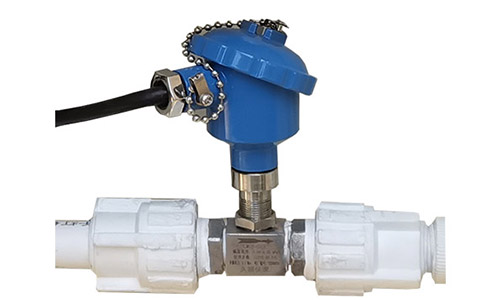

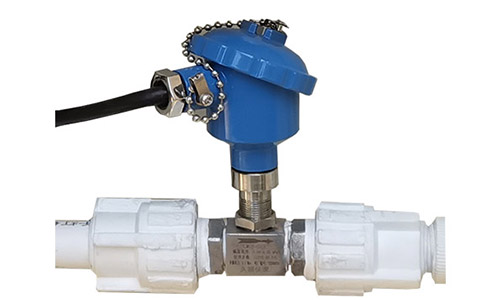

⑤ Pressure sensor | Used to monitor the water spray pressure in real time to ensure that the water spray pressure is within the range required by the IPX4 test to ensure the accuracy and reliability of the test results. |  |

⑥ Flowmeter | The flow rate of IPX3 is required to reach 1.8L/min±5, and the flow rate of IPX4 is required to reach 2.6L/min±5. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español