Features and Benefits of MIL STD 810 Test Chamber

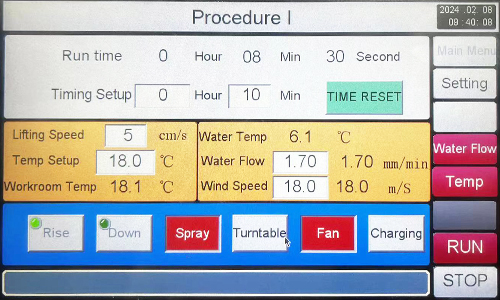

1. Simulate rainfall of various intensity, including light rain, moderate rain, heavy rain and even heavy rain, to test the waterproof performance of the product under different rainfall conditions. Such as continuous rainfall, intermittent rainfall and so on.

2. Precise control of rainfall, rainfall rate, wind speed and other parameters. Rain rate ≥1.7mm/min, raindrop size range between 0.5mm-4.5mm, wind speed can reach ≥18m/s, wind and rain collaborative simulation.

3. Equipped with an automatic water recirculation system, the workroom has a drain, which can recover and treat the used water and recycle it, thus reducing the waste of water resources and reducing the complexity of manual water control.

4. The MIL-STD-810H test standard is highly authoritative and widely accepted in the global military field as well as in the civilian field with high reliability requirements (such as aerospace, high-end electronics, etc.).

Specifications of MIL STD 810 Test Chamber

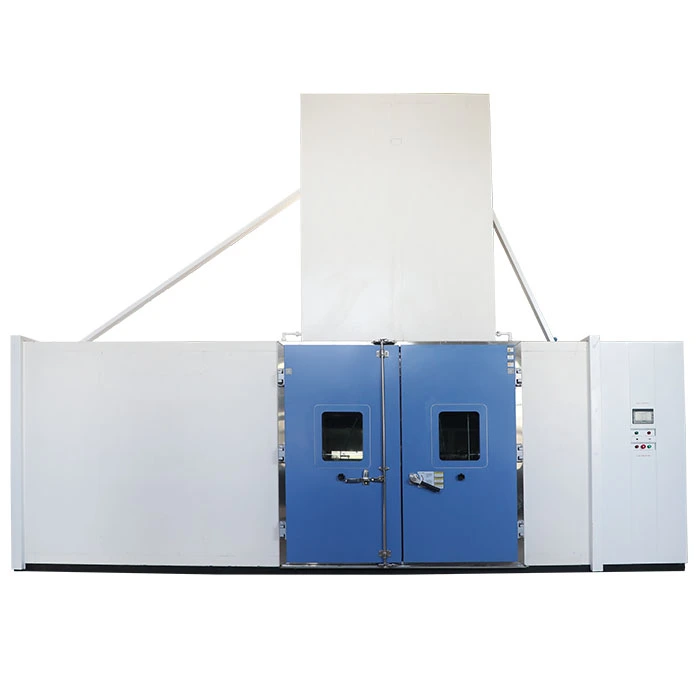

Model | RM-1000 |

Internal Dimension | 1000*1000*1000 mm D*W*H |

Overall Dimension | 2600*5400*4100 D*W*H |

Interior Volume | 1000L |

The load Turntable | 50kg |

The diameter of Turntable | 800mm |

Rain and Blowing Rain |

|

Final rain droplet velocity | 9m/s on test item |

Rainfall rate | ≥ 1.7 mm/min |

Droplet size | 0.5mm ~ 4.5mm |

Test specimen heating range | Water temperature +10°C (max +55°C) |

Test time | 0 ~ 999min. adjustable |

Exaggerated |

|

Nozzle pressure | 276kpa |

Rainfall rate | 20.8L/min |

Nozzle amount | One nozzle for each 0.56m2 of surface area and position each about 48cm from in the test surface |

Droplet size | 0.5mm ~ 4.5mm |

Test time | 0 ~ 999min. adjustable |

Drip |

|

Drip area dimensions | 1600*1000mm , height can be adjustable |

Drip holes | 20 to 25.4mm |

Distance between hole | 25mm |

Volume of water | ≥280L/m2/h |

Test specimen heating range | Water temperature +10°C (max +55°C) |

Door Lock | Electromagnetic lock |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Standard | MIL-STD- 810H |

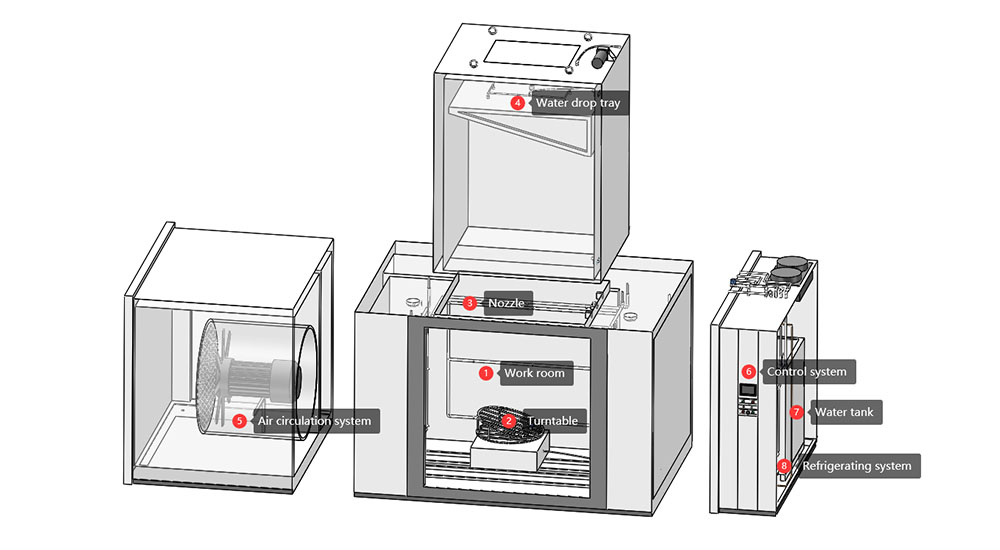

Configuration of MIL STD 810 Test Chamber

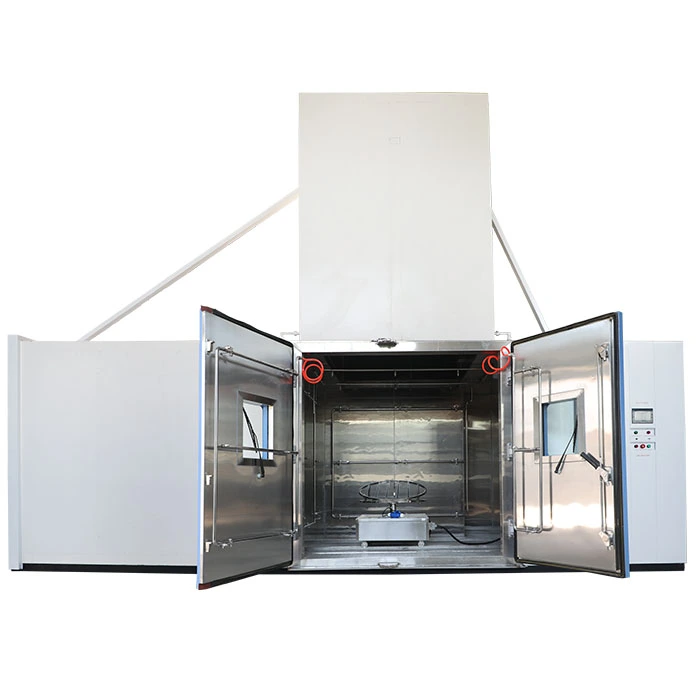

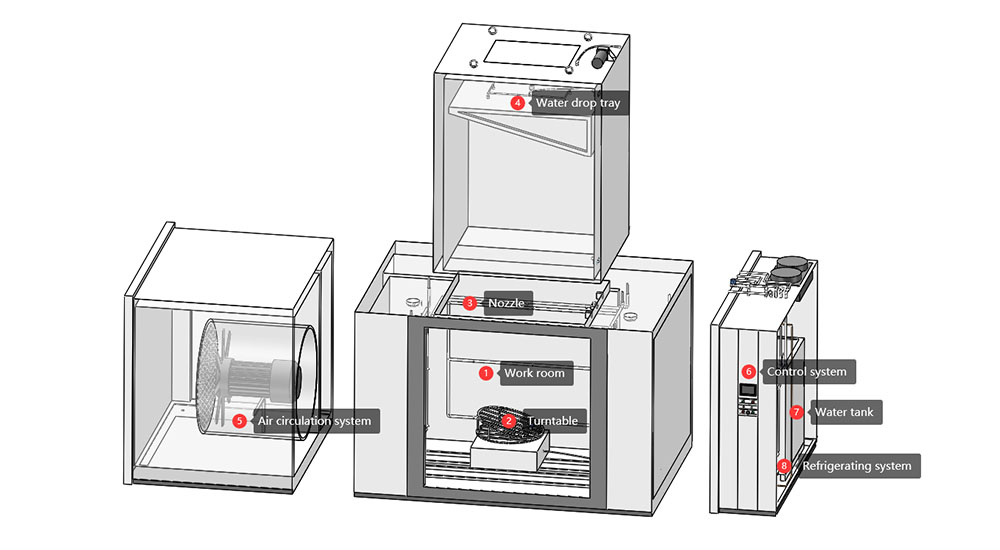

① Workroom | SUS304 stainless steel material, with good corrosion resistance, to prevent rain erosion and rust. The workroom is equipped with a wind speed probe. The shell of the test chamber is made of A3 steel plate with protective coating, which has good structural strength and corrosion resistance.

|  |

② Turntable | Adjustable speed turntable, the speed is 1-7r/min, the turntable can move left and right along the track. Turntable equipped with waterproof power supply.

|  |

③ Nozzle | The workroom is equipped with 360 rotating nozzles on the front, rear, left and right sides, which can spray water at different angles to the product, and strengthen the test through the nozzles. |  |

④ Drip tray | Located at the top of the workroom. The drip tray can be adjusted by the upper screw reducer, and the limit device limits the drip pan. In order to accommodate different sizes and types of product testing requirements.

|  |

⑤ Air circulation system | The axial fan is located on the left side of the workroom. Generates airflow that, combined with rainfall conditions, more realistically simulates wind and rain conditions.The air is continuously circulated through the air duct.

|  |

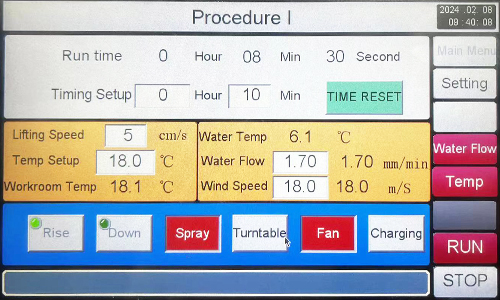

⑥ Control system | Programmable color touch screen controller can set and adjust various test parameters, such as rainfall time, rainfall intensity, wind speed, temperature, turntable speed, etc. At the same time, the monitoring and recording function is perfect. |  |

⑦ Water tank | Store the water required for the test with a high-low water float to ensure a continuous supply of water during the test. The difference between the rain water temperature and the measured part temperature should be 10 ° C, and the water temperature should be adjusted. The water tank is equipped with heating tube and evaporator to cool the water supply.

|  |

⑧ Refrigerating system | Adopt mechanical compression refrigeration method. Including compressor, condenser, evaporator, throttling device. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español