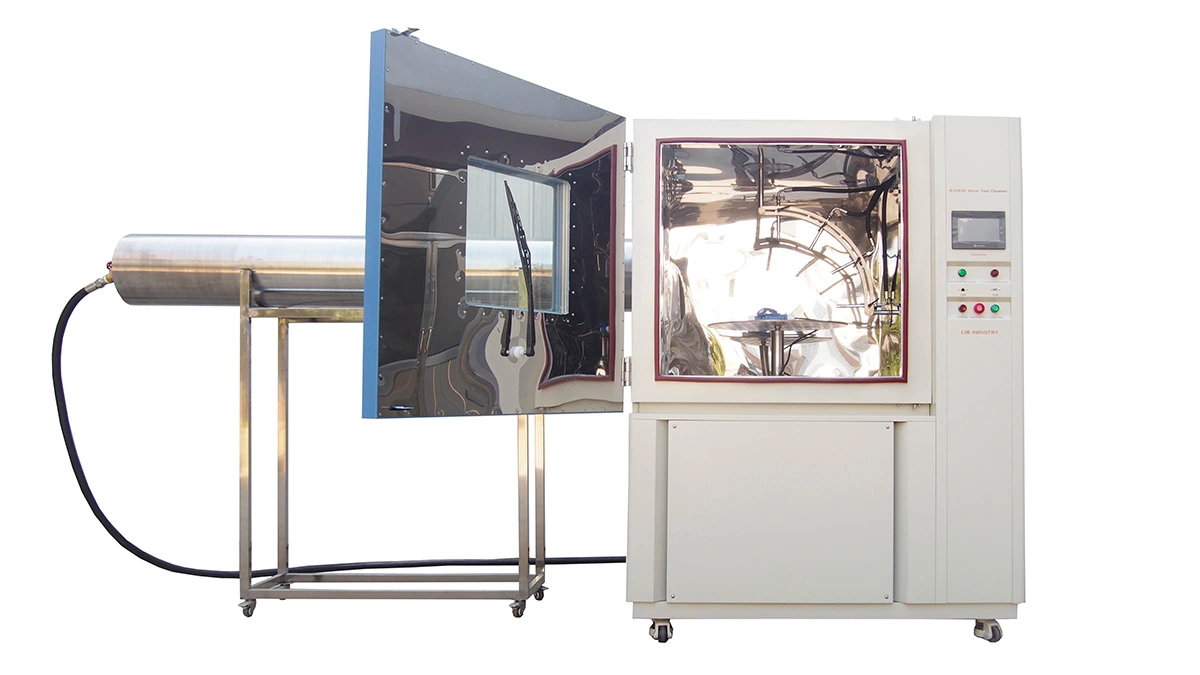

Assessing the weatherability of materials is critical to their application for materials science. The accelerated weathering test can quickly simulate natural aging, and the xenon arc chamber complying with ASTM G155 standard has become the core equipment of the test because it can accurately reproduce a variety of environmental factors.

(1) The mystery of xenon arc lamp

Xenon arc lamps can emit light similar to the natural light spectrum, its spectral range is usually 300-400 nm, in which the ultraviolet part (such as 290-400 nm UVA and UVB band) can trigger the photochemical reaction of the material, which is the "catalyst" of the material aging. Its stable and adjustable lighting provides a reliable light source basis for the test, and the light intensity can be adjusted between 35 and 150W/m² to meet the needs of different material testing.

(2) The exquisite control of temperature and humidity

The ASTM G155 test chamber uses a complex sensor and control system to accurately set and adjust temperature and humidity in real time. This not only simulates day and night and seasonal temperature differences (ambient to +100°C ), but also creates a variety of humidity environments (50%-98% RH relative humidity), allowing the material to be tested under different temperature and humidity combinations, as if it were in a real climate change.

(3) The synergistic effect of spray and condensation

The spray system can simulate rainfall.The condensation system cleverly creates condensation on the surface of the sample, like morning dew. The two cooperate with each other to further aggravate the aging process of materials, especially water-sensitive materials will face more severe challenges.

(1) Ultraviolet radiation: the "invisible killer" of material aging

The ultraviolet radiation generated by the xenon arc lamp can destroy the chemical bonds within the material molecules, reduce the mechanical properties of plastics, rubber and other materials, fade the pigment, and powder the coating. After prolonged exposure to this simulated UV light, the material rapidly exhibits aging characteristics that would take years to appear in the natural environment. For example, under a specific ultraviolet intensity, a certain plastic sample after 500 hours of xenon arc test chamber irradiation, tensile strength decreased by 30%, color difference reached 5 units.

(2) Temperature change: "regulator" of material properties

The temperature of the natural environment is variable, and the xenon test chamber can simulate this characteristic. High temperature can make thermoplastic materials soften and deform, and metal materials expand; Low temperatures make rubber brittle and plastics less ductile.

(3) Humidity and condensate: silent "erosion"

Humidity plays a key role in material weathering, and high humidity can make porous materials absorb water and expand, and metal materials accelerate corrosion. Condensation water carries impurities and the material reaction, such as building exterior wall paint in high humidity and condensed water environment, after 800 hours of test, the surface foaming, peeling phenomenon, coating adhesion decreased by 60%.

(4) Rain: the "sander" of the material surface

The spray system simulates the rain, the raindrop impact force and the chemical composition of the rain to erode the surface of the material. For metal materials, acid rain can speed up the surface corrosion rate, such as a certain aluminum alloy after 1000 hours of simulated acid rain spray, the corrosion depth reaches 0.5mm.

(1) The automobile industry

Automotive coatings and components need to withstand a variety of weather conditions. Xenon arc test chamber can simulate different regions and seasons, after the test, gloss retention rate, color change, adhesion and other indicators become the key to evaluate the quality and life of automotive coatings. For example, after 1500 hours of xenon arc test, the gloss retention rate is more than 80%, and the color difference is controlled within 3 units, which meets the industry's weather resistance standards.

(2) Construction industry

Building materials such as exterior wall coatings and roofing materials are exposed outdoors for a long time. Through xenon arc test chamber simulation, after 2000 hours of test, the degree of powder, fading grade, cracking condition are the basis to judge its weather resistance. For example, a high-quality exterior wall coating after the test, the degree of powder is less than 10%, the fading grade is less than 2, and the service life of more than 10 years can be guaranteed.

(3) Plastics and rubber industry

Plastic and rubber products are widely used, and their weather resistance affects product performance. In the xenon arc test chamber, the change of plastic tensile strength and elongation at break reflects the degree of aging. For example, after 1000 hours of test for a plastic pipe, the tensile strength retention rate is 70%, which meets the relevant pipe application standards. Rubber products are evaluated by hardness changes and cracks, such as rubber tires after simulated aging test, the hardness change does not exceed 20%, no obvious cracks, which can ensure driving safety and life.

(4) Textile industry

The color fastness and fiber strength of textiles are affected by the environment. After simulated lighting in xenon arc test chamber, textile color fastness rating (such as 1-5, above 4 is qualified) and fiber strength retention rate are important indicators. For example, after 500 hours of testing, the color fastness of an outdoor clothing fabric reaches 4-5 levels, and the fiber strength retention rate is above 75%, which can meet the needs of long-term outdoor use.

Xenon arc test chamber plays a key role in accelerated weathering test. It plays a key role in multi-industry material testing by accurately simulating natural environmental factors. Compared with other test methods, it has obvious advantages. Although the accuracy of test results is affected by many factors, strict control of parameters, attention to data quality and reasonable evaluation of life, combined with correct operation and maintenance, can provide strong support for the research of material weather resistance, and promote the development and progress of materials science and technology in various industries.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia