Features and Benefits of IPX7 Diving Test Chamber

1. Precise simulation of IPX7 standard 1 meter water depth immersion environment, equipment is equipped with an accurate water level control system, so that product testing conditions standardized.

2. Monitoring can be installed in the stainless steel water tank to directly observe the state of the product in the water, including whether there are bubbles, whether the product structure is deformed, etc.

3. In addition to standard pressure immersion test equipment, custom immersion can be provided according to the size of the test piece and the required pressure, for example, to simulate water pressure up to 100 meters deep.

4. Cylindrical water tank, strong pressure capacity, three M8 hole Z-shaped tripod at the bottom, good grip. Users need to fasten the equipment with screws to ensure safety.

Specifications of IPX7 Diving Test Chamber

Model | R78-600 |

Internal Dimension (mm) | Diameter 600mm * Height 1500 mm |

Overall Dimension (mm) | Diameter 800mm * Height 1800 mm |

Pressure | 50m water depth pressure |

Open mode | Pneumatic lid |

Material | A3 steel plate, wall thickness 15mm |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water Supply System | Storage water tank, Automatic water supply |

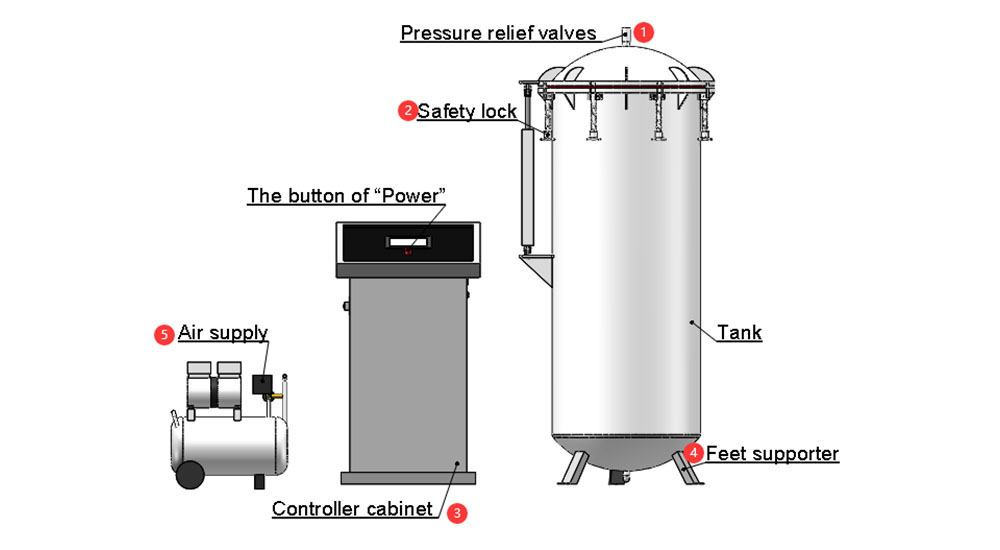

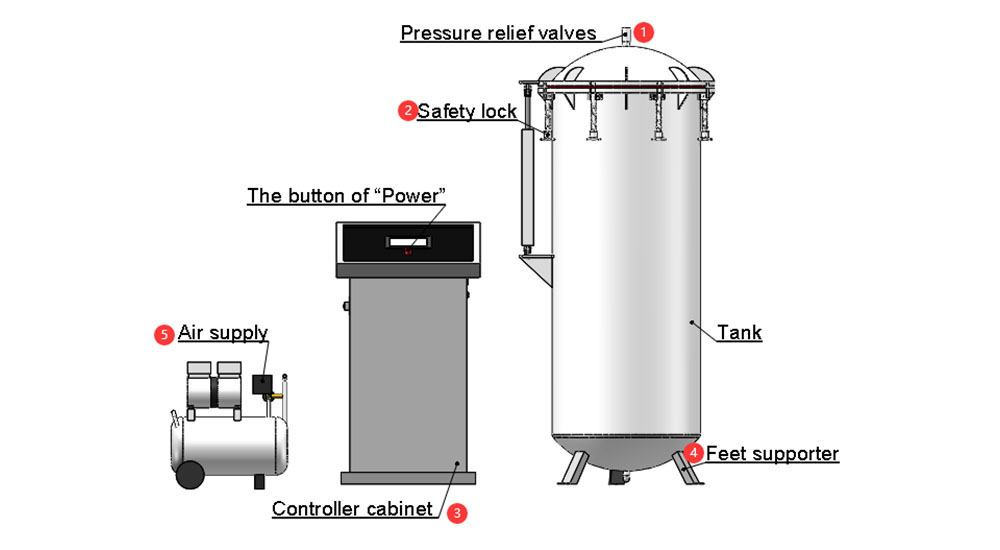

Configuration of IPX7 Diving Test Chamber

① Pressure relief valve | When the pressure in the IPX7 diving test chamber exceeds the set safe value, the release pressure is opened to prevent damage to the equipment and internal samples caused by excessive pressure. |

② Safety lock | 12 manual safety locks. To prevent the test chamber from opening accidentally during the test, to ensure the stability of the pressure in the test chamber, the safety of the operator and the accuracy of the test results. |

③ Controller cabinet | Centrally control the operation and parameter setting of the test chamber, such as controlling the test time, pressure regulation, temperature control, etc., and have the function of displaying the working status and parameters. |

④ Feet supporter | Three M8 hole Z-shaped tripod with good grip to keep equipment stable. |

⑤ Air supply | Air supply for the pneumatic rod. |

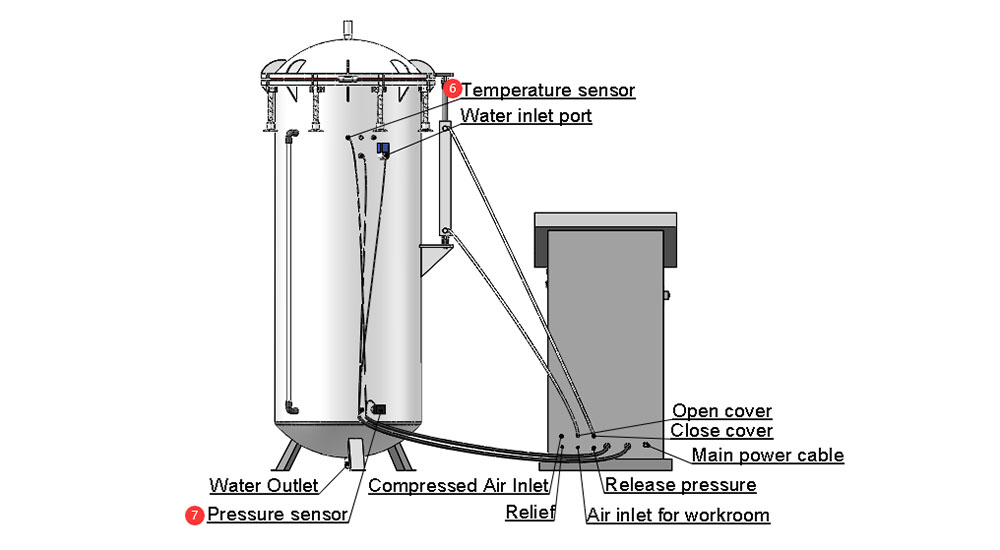

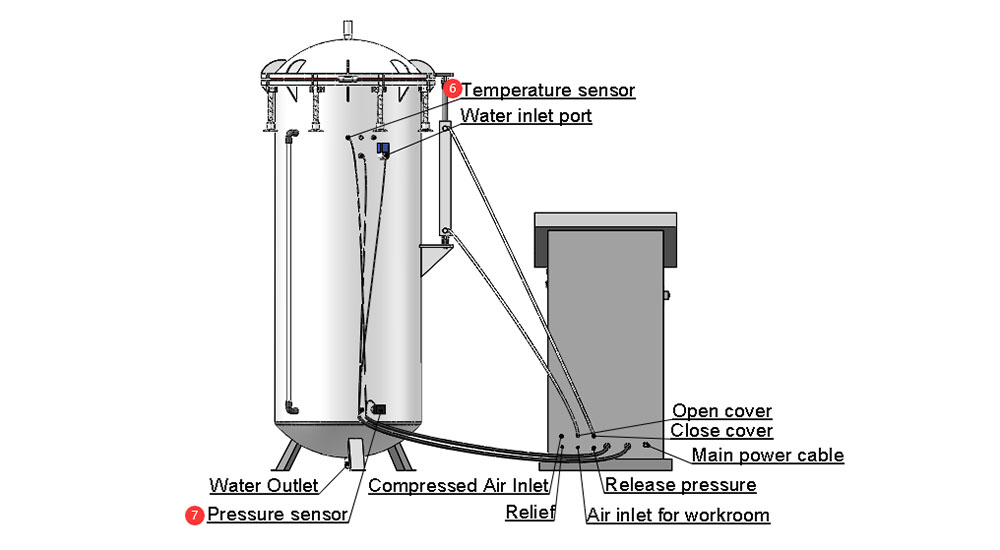

⑥ Temperature sensor | Monitor the internal temperature of the test chamber in real time. |

⑦ Pressure sensor | In the IPX7 test, when the product is subjected to underwater pressure testing, the pressure probe provides real-time feedback pressure data. |

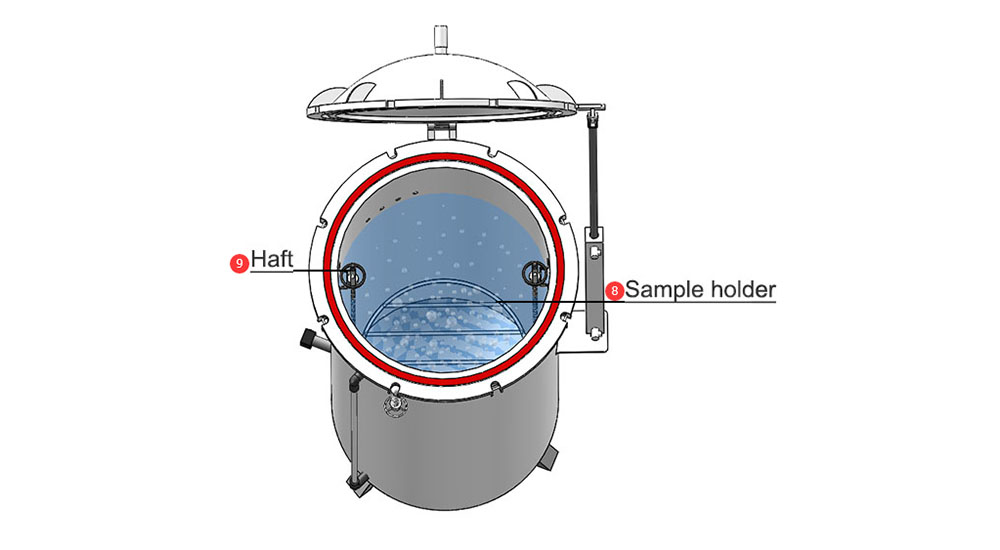

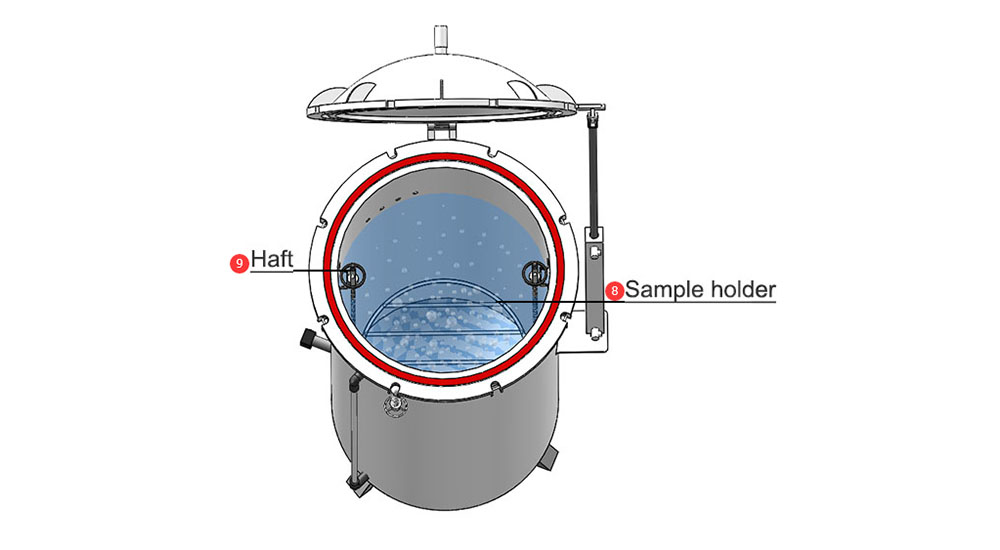

⑧ Sample holder | fix and place the product sample to be tested,It can be customized according to different product shapes, sizes and test requirements, and the height in the test chamber can be adjusted, bearing 50KG. |

⑨ Haft | Sample holder can aligned on both sides of the haft.

|

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español