ASTM G155 is one of the most widely used xenon laboratory accelerated burn-in testing standards in the world and has been updated many times. This test method is referenced in many other standards.

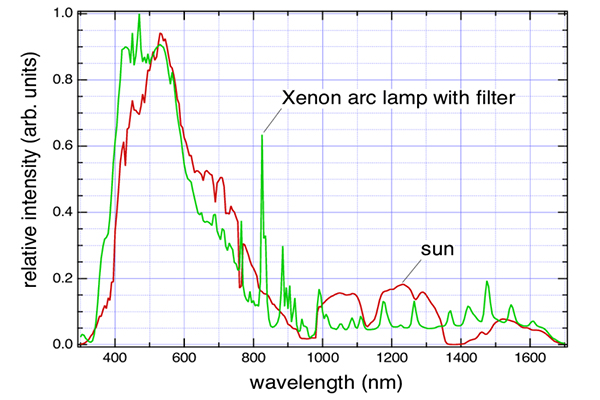

The ASTM G155 test chamber is a xenon lamp test chamber that meets the standard. Xenon arc lamps with a high convergence with the full sunlight spectrum in nature are used to simulate natural sunlight and reproduce the destructive light waves of sunlight in different environments, so that the material can be well tested for light resistance and weather resistance.

It can be used for screening new materials, improving existing materials or evaluating changes in durability after changes in material composition, and is widely used in plastic and rubber materials, coatings and coatings, textiles and other fields.

This standard describes that the testing samples exposed to xenon arc lamps simulating natural sunlight (directly or through glass) and spray devices used or simulating dew or raindrops in a humid environment, as required by the characteristics of the material or product.

Model | XL-S-750 |

Internal Dimension (mm) | 950*950*850 mm |

Overall Dimension (mm) | 1400*1400*1950 mm |

Specimen Holder Size(mm) | 95*200 |

Specimen Capacity | 42pcs |

Chamber Type | Rotating Holder |

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Humidity Deviation | ± 5% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

| |

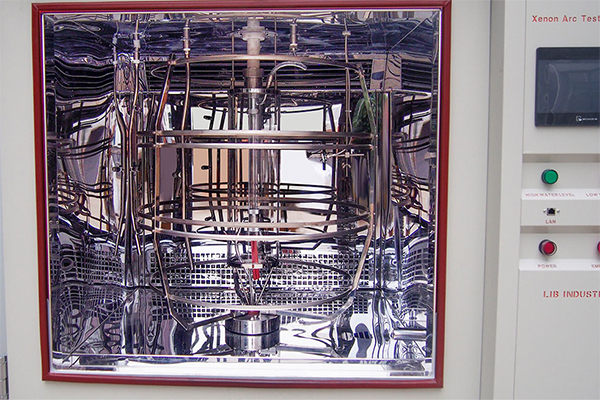

ASTM G155 test chamber uses high-quality xenon arc lamp as light source, which can produce high intensity and stable light to meet the requirements of irradiation test, and can be exposed to various shapes and sizes of samples. The irradiation range is 35~150 W/㎡. LIB ASTM G155 test chamber can directly set and automatically control the irradiation energy (340nm, 420nm, 300nm ~ 400nm, 300nm ~ 800nm) through the PID controller and the controllable range is wide, and the system automatically monitors and adjusts the irradiation energy deviation caused by the aging of the lamp and other reasons.

Using advanced water-cooled xenon lamps, the cooling speed is fast, and the average service life can reach 1600h.The operator can set the total test time or the total irradiation energy to end the test.

The ASTM G155 test chamber is equipped with heating and cooling system, which can accurately control the temperature according to the need, the temperature range is from room temperature to 100℃, and directly set and automatically control the temperature of the studio and the blackboard. Humidity control is usually achieved through a humidity regulator or evaporator to maintain a specific humidity level, ranging from 50% to 98% RH. The chamber is equipped with a forced circulation fan system to ensure a uniform distribution of temperature and humidity in the chamber for a more realistic climate simulation.

At the same time, ASTM G155 test chamber is equipped with a spray system, water spray can be sprayed under dark conditions or under light conditions, you can also choose positive spray and back spray, water can be recycled, reducing equipment operation and maintenance costs.

In ASTM G155 test chamber, there are two common types of sample holder, flat sample holder and rotary sample holder.A flat sample holder is usually a flat tray on which the sample can be placed smoothly. Easy to place and secure samples.On the rotating sample rack, the test piece rotates around the xenon lamp, so that the irradiance received by the test piece is relatively uniform, the test error caused by the position difference is reduced, and the test piece is stretched to a certain extent.

In practical applications, users can choose the right type of sample holder according to the characteristics of the test parts and test requirements to ensure accurate and reliable test results.

ASTM G155 test chamber studies the aging rate, elastic loss, cracking and other phenomena of rubber products such as tires and seals in simulated natural environment to improve rubber formulation and production process. In the field of coatings and coatings, the weather resistance, fading, adhesion changes of coatings are detected to help select high-quality coatings suitable for outdoor use and determine their protective properties and service life.

The ASTM G155 test chamber can also be used to test clothing fabrics to determine the ultraviolet resistance of fabrics, color fastness and fiber strength changes, and to develop outdoor clothing and functional textiles with good weather resistance. For example, in the home textiles industry, ASTM G155 test chambers evaluate the fading and durability of home textiles such as curtains and carpets under light and everyday use conditions.

ASTM G155 test chamber is used to test the reliability and stability of the shell materials and packaging materials of electronic components under light and temperature and humidity conditions to ensure the normal operation of electronic equipment in various environments. It also includes testing wire and cable: testing the aging performance of the insulation layer and sheath material of wire and cable to prevent leakage, short circuit and other safety hazards in use.

The ASTM G155 test chamber has irreplaceable advantages in the field of material testing due to its high-precision irradiation control, accurate temperature and humidity simulation, good repeatability and reliability. Its applications in plastics, rubber, coatings, textiles and other industries provide strong support for material quality control and research and development.

The above is the introduction of ASTM G155 test chamber , if you want to know more information, click here to view the more details. If you need professional help and solutions, please contact us inquiry@libtestchamber.com , professional team is online to provide you with tailor-made solutions.