For many products used in harsh environments, they face a dusty and rainy environment, especially products that need to work outdoors, such as auto parts, outdoor electronic equipment, industrial machinery, etc., with good protective performance is essential. The IP6K9K test chamber has become an important tool to verify the protection performance of these products in harsh environments.

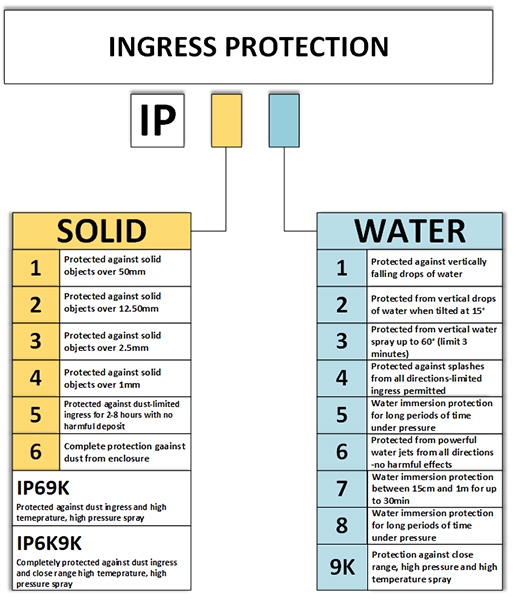

IP Protection (Ingress Protection) is used internationally to define the level of protection of electrical equipment enclosures against foreign body intrusion. Among them, IP6K9K represents the highest level of protection, able to withstand the impact of high temperature, high pressure water jets and dust intrusion. This level of protection is extremely strict, designed to ensure that the product can still work properly under extremely harsh conditions, without interference and damage from external environmental factors.

IP6K9K is a class of protective construction specified by DIN40050 Part 9. 6K waterproof: not affected by strong water jet impact, 9k waterproof: not affected by the harmful effects of high temperature and high pressure water jet erosion.

Before officially introducing the IP6K9K test chamber, we must first clarify the concept that IP6K9K is not a standard IP protection level. IP6K9K is a general concept of the common IPX6K and IPX9K collections. The IP protection level is composed of two numbers, the first number indicates the level of protection for solid particles, and the second number indicates the level of protection for liquids. For example, IP67 means that the device has a protection level that is completely dust-proof and can be immersed in water for a short period of time without damage.

So, what does "K" mean? In fact, the "K" in ip6k9k is not part of the IP protection level. In the IP protection level, "K" usually appears in some specific test standards, such as IPX9K, indicating that the equipment can withstand water spray tests under high temperature and pressure. The "K" here stands for "supercharge."

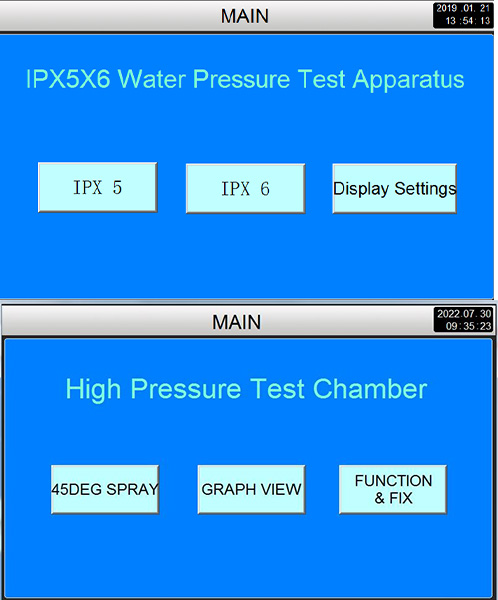

The IPX6K test chamber of LIB brand can carry out strong water spray test on the product, the range is 2.5m ~ 3m, and the water flow is (100±5) L/min. Simulate high intensity water impact environment to ensure the waterproof ability of the product shell in severe weather conditions such as heavy rain. The water pressure of the sprinkler system is adjusted according to the water flow. ipx6k and ipx6 compared to ipx6k, ipx6k has an additional booster water strengthening function.

The internal space of IPX6K test chamber is reasonably designed, and the models are diverse, which can accommodate products of different sizes. The turntable and fixture inside can firmly fix the products to ensure the stability and accuracy of the test.

Model | R56-800 |

Workroom dimension (mm) | 800*800*800 |

External dimension (mm) | 950*3150*1800 |

Interior Volume (L) | 510 |

Diameter of Turntable (mm) | 600 |

Turntable Rotation Speed | 0~7r/min (Adjustable) |

Internal Diameter of IPX5 Nozzle | 6.3mm |

Internal Diameter of IPX6 Nozzle | 12.5mm |

Water Flow Rate IPX5/ IPX6 | 12.5L/min ±5% / 100L/min ±5% |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water Supply System | Water tank, booster pump, Automatic water supply, Water purification system |

| |

The IPX9K test chamber focuses on high temperature and high pressure water spray testing. Activate the sprinkler system in the laboratory. The temperature of the water jet is heated to around 80 ° C and the pressure can be as high as 1000 kilopascals. Water jets continuously spray products from different angles such as 0°, 30°, 60°, 90°. The spraying time at each Angle is usually not less than 30 seconds to fully inspect all parts of the product housing. In the process of spraying, it will closely observe whether the product has water leakage, seepage phenomenon, and whether the appearance of the product is deformed and damaged. The test chamber is equipped with an advanced temperature and pressure control system, which can monitor and adjust test parameters in real time to ensure that the test conditions meet the standard requirements.

Model | R9K-1200 |

Internal Dimensions (mm) | 1000*1200*1000 |

Overall Dimensions (mm) | 1250*1700*2050 |

Interior Volume (L) | 1200 |

Water Spray Angle | 0°, 30°, 60°, 90° |

Water Spray Temperature | Ambient ~ +88℃ (Adjustable) |

Spray Nozzle | Four, 30 Seconds each position |

Distance from Water Spraying to Specimens | 10~15cm |

Water Pressure | 8000-10000 Kpa (Adjustable) |

Water Flow Rate | 14L-16L/min |

Testing Platform Speed | 5±1 r.p.m |

Testing Platform Height | 200-400 nm (Adjustable) |

Testing Platform Diameters | 600mm |

| |

A wide range of industries benefit from the rigorous testing of the IP6K9K test chamber. In the automotive industry, engine components, sensors and lights are all required to pass IP6K9K testing to ensure proper operation in all weather and road conditions. Especially in some extreme climate areas, the protective performance of auto parts is directly related to the safety and reliability of cars.

Outdoor electronic equipment field: such as outdoor lighting, surveillance cameras, solar power generation equipment, etc., are often exposed to wind, sun, rain and dust in the environment. The IPX6K9K test chamber can simulate these harsh conditions and verify the protection performance of the product.

Industrial automation and machinery manufacturing industry: In industrial production lines, many equipment are faced with high temperature, high pressure water cleaning and dust pollution. Such as industrial robots, automation control equipment, motors, etc., the IPX6K9K test chamber can help enterprises ensure that these equipment operate normally in harsh industrial environments, reduce the downtime caused by environmental factors, and improve production efficiency and product quality.

The IP6K9K test chamber is rated according to DIN 40050-9:1993, ISO 20653:2013, IEC 60529:2013 and other standards. With the advancement of technology, the LIB IP6K9K upgraded test chamber is more intelligent, can automatically test and collect data, improve efficiency and accuracy, and can also be combined with other environmental test equipment for more complex comprehensive performance tests.

If you are struggling with the harsh environmental protection performance testing of your product, the IPX6K9K test chamber of the LIB brand will be the ideal choice for you. Please contact us inquiry@libtestchamber.com for more details about the test chamber and we will give you the best plan and quotation.