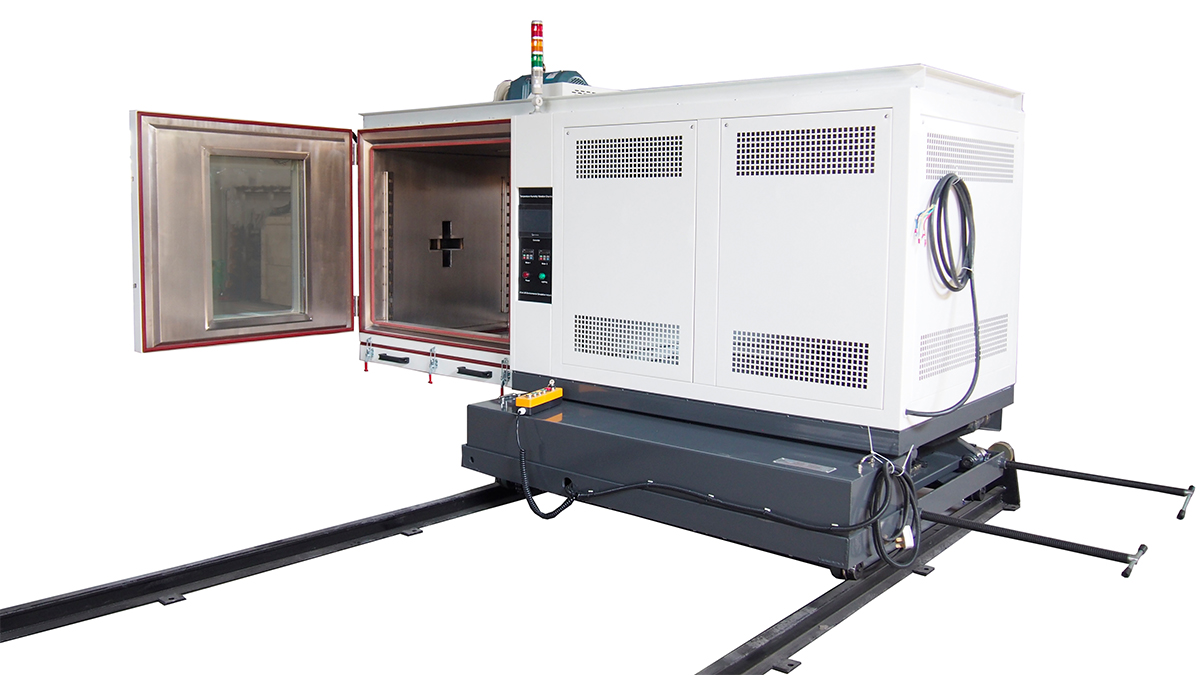

A vibration chamber, also known as a vibration test chamber or vibration table, is a device used to simulate and test the performance and reliability of products or structures in a vibrating environment. Here are the basic working principles of a vibration chamber:

Vibration Table: The core part of the vibration chamber, responsible for generating vibrations.

Controller: Used to control the vibration parameters of the vibration table, such as frequency, amplitude, and vibration mode.

Fixtures and Mounting Devices: Used to secure the product to be tested on the vibration table.

Monitoring and Recording Equipment: Used to monitor vibration parameters and record test results.

Vibration Table: Usually consists of one or more exciters, which can be electric, hydraulic, or pneumatic. Electric exciters generate vibrations through electromagnetic forces, while hydraulic or pneumatic exciters are driven by fluid pressure.

Vibration Generation: When the exciter is activated, it produces vibrations that are transmitted through the vibration table to the test sample mounted on it.

Parameter Control: Through the controller, the operator can set the vibration frequency (speed of vibration), amplitude (intensity of vibration), and vibration mode (e.g., sinusoidal, random vibration, shock). The controller precisely adjusts the output of the exciter to achieve the desired vibration conditions.

Environmental Simulation: The vibration chamber can simulate various vibration conditions that might be encountered in real environments, such as transportation vibration, operational vibration, seismic vibration, etc.

Test Execution: The test sample is fixed on the vibration table, and the vibration table begins to vibrate according to the preset program. During the test, monitoring equipment records the sample's response, such as structural integrity, functional performance, and fatigue life.

Data Analysis: After the test is completed, the collected data is analyzed to evaluate the sample's performance in the vibrating environment and to determine whether it meets the design requirements.

Vibration chambers are widely used in aerospace, automotive, electronics, military, construction, and many other industries for product design and quality assurance.

Through testing in a vibration chamber, potential defects in products under vibrating conditions can be revealed, leading to improved design and increased reliability and durability of the products.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia