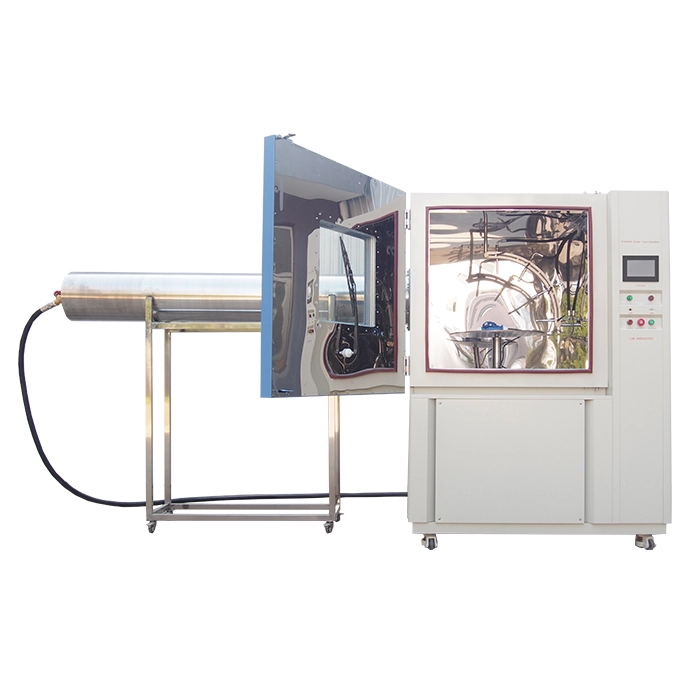

Features and Benefits of IP69K Test Chamber

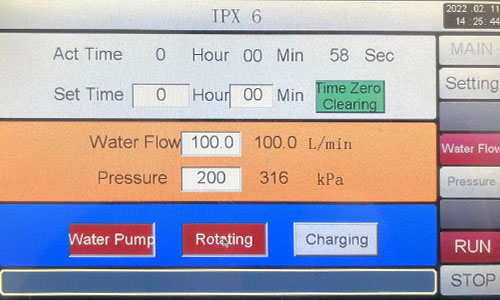

1. Through the advanced pressure regulator, solenoid valve and other devices, precise control of water pressure and flow, for IPX6K test, can stably provide 1000kPa water pressure, for IPX9K test, can reach 8000kPa-10000kPa high water pressure.

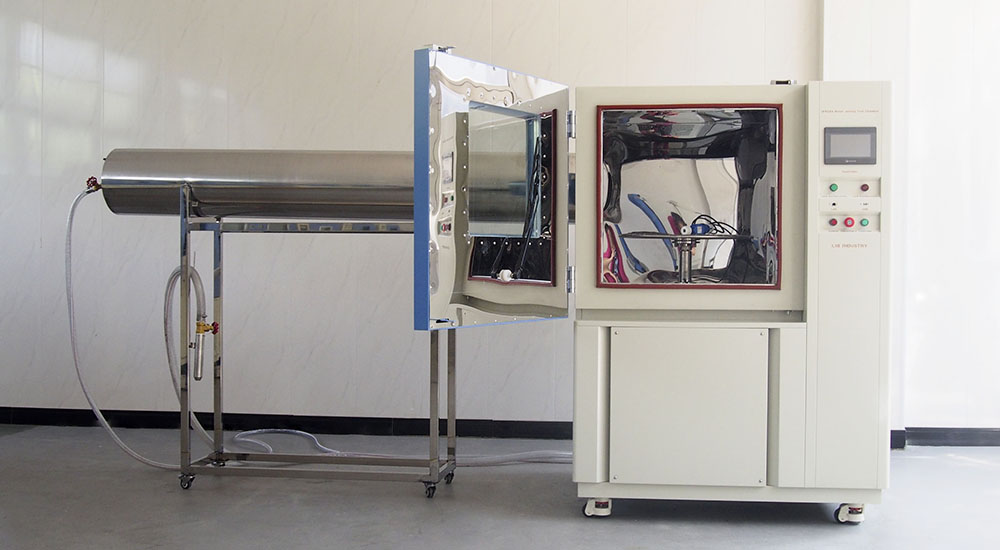

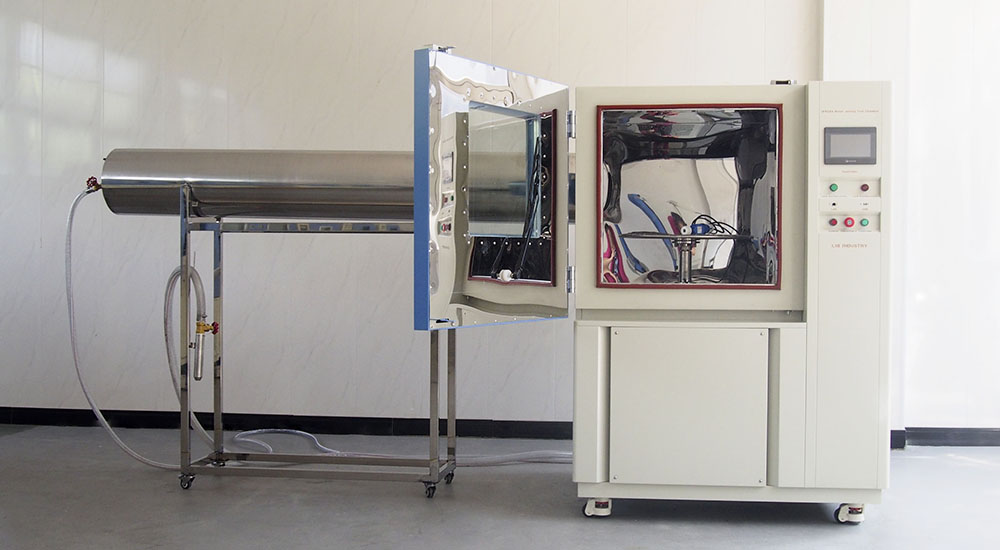

2. Cover a variety of waterproof levels: one chamber can meet the IPX5, IPX6, IPX6K, IPX9K at the same time, there is no need to buy multiple different test equipment, saving procurement costs and test site space.

3. The overall structure is firm, and the outer chamber is made of 4MM A3 steel plate. The workroom uses SUS304 stainless steel, good corrosion resistance, easy to clean and maintain.

4. Rubber sealing materials are used to seal the test chamber between the door and the chamber, the pipe joints and other places where there may be gaps to ensure that water does not leak during the test.

Specifications of IP69K Test Chamber

Model | R6K9K-1200 |

Internal Dimensions (mm) | 1000*1200*1000 D*W*H |

Overall Dimensions (mm) | 1150*3550*2100 D*W*H |

Interior Volume (L) | 1200 |

Parameter | Testing Platform Diameters | 600mm |

Testing Platform Speed | 5±1 r.p.m |

Turntable loads | 50kgs |

Testing Platform Height | 200-400 mm (adjustable) |

IPX6K | Internal Diameter of Nozzle | 6.3mm |

Water Flow Rate | 75 L/min +/- 5% |

Water pressure | 1000 Kpa |

Distance fromWater Spraying to Specimens | between 2.5 m and 3 m. |

IPX9K | Water Spray Angle | 0°, 30°, 60°, 90° |

Water Spray Temperature | Ambient ~ +88℃ (Adjustable) |

Spray Nozzle | Four, 30 Seconds each position |

Distance fromWater Spraying to Specimens | 10~15cm |

Water Pressure | 8000-10000 Kpa (Adjustable) |

Water Flow Rate | 14L-16L/min |

Temperature Sensor | PTR Platinum Resistance PT100Ω/MV A-class |

Heater Elements | Nichrome heater |

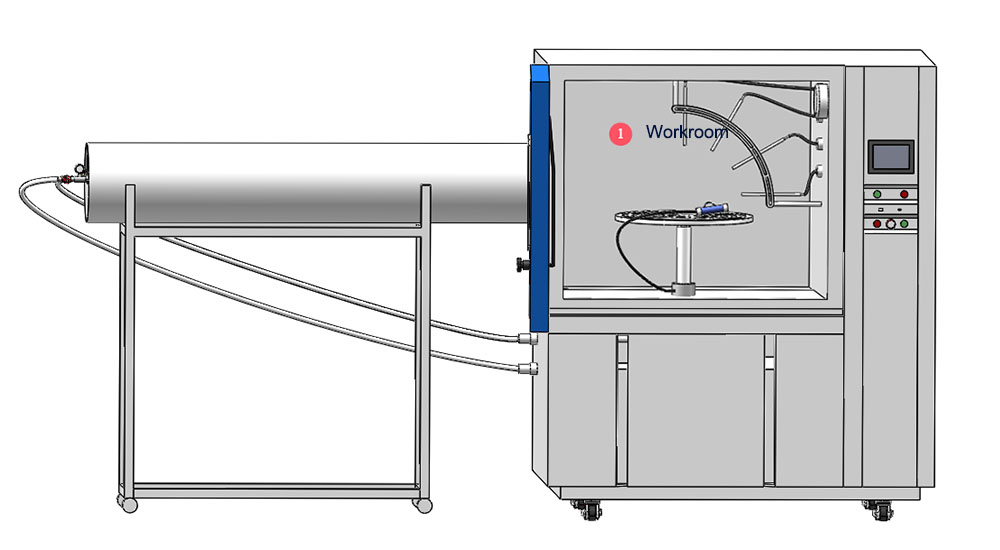

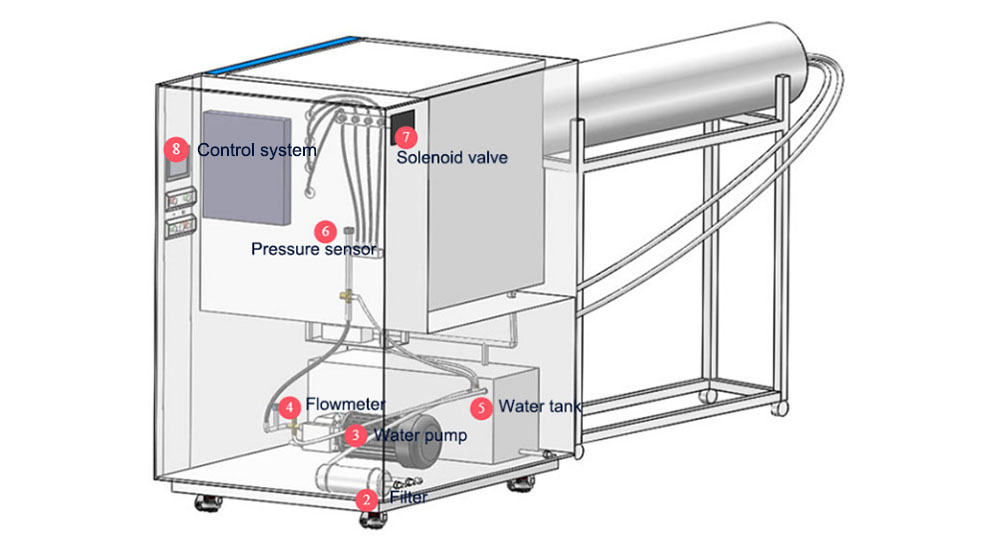

Configuration of IP69K Test Chamber

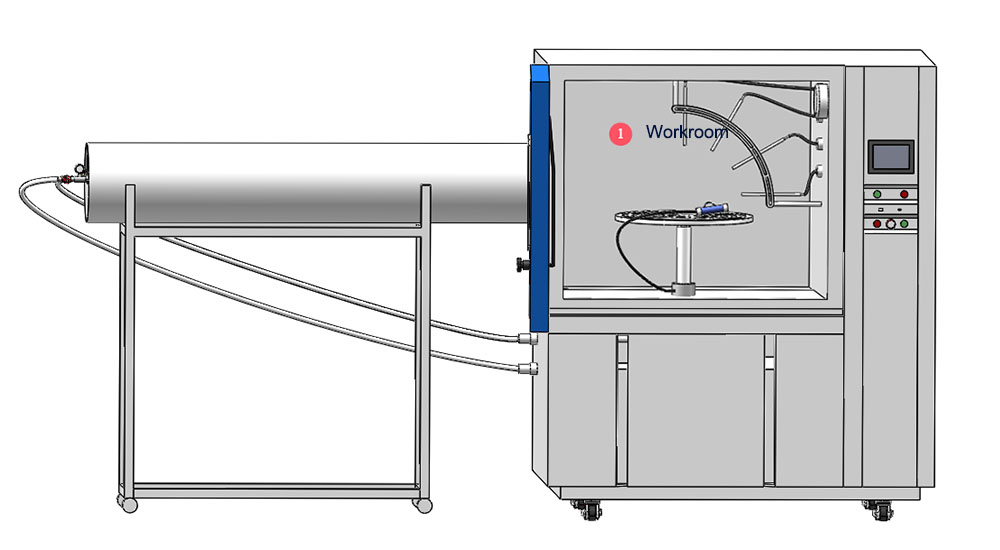

① Workroom | Turntable adjustable speed, adjustable height, bearing 50kg, with waterproof power supply. 4 nozzles for IPX9K test, 4 nozzle angles are 0°, 30°, 60°, 90°. A hole is opened on the left side of the workroom for IPX6K testing, and the spacing between the nozzle and the test piece is 2.5m ~3m.

|  |

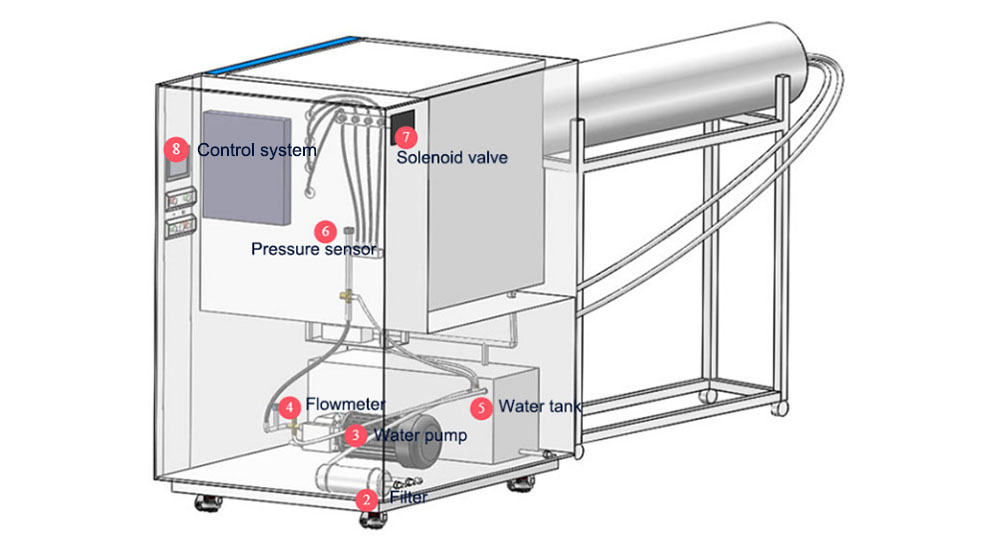

② Filter | Automatic inlet filter, can filter out 0.03MM diameter of impurities, to ensure the smooth flow of spray. A complete water recycling system to save water.

|  |

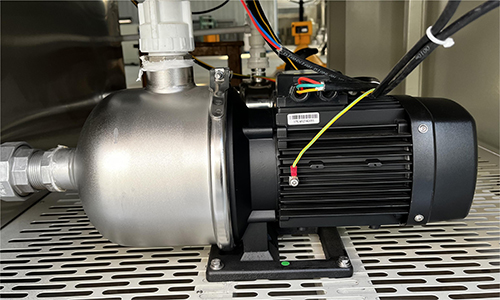

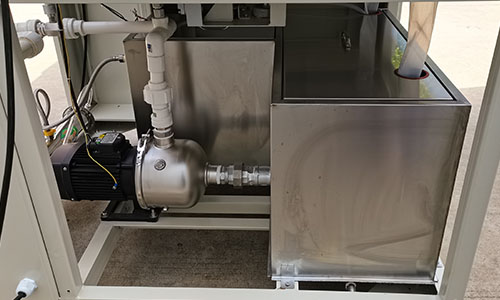

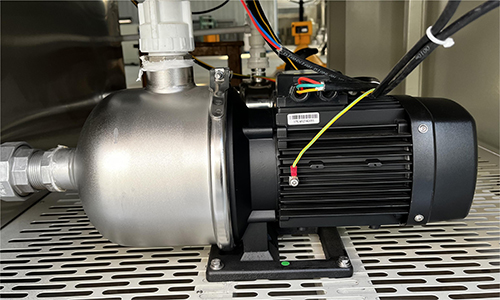

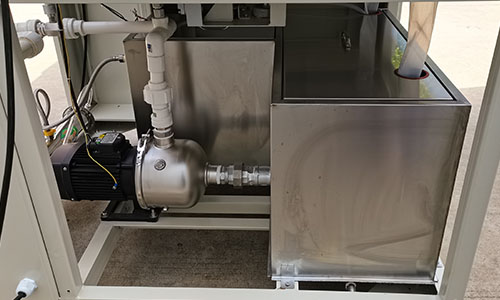

③ Water pump | For the core components that produce high-pressure water spraying, 1000kPa water pressure is required for IPX6K testing; For IPX9K tests, the water pressure should reach 8000kPa-10000kPa. |  |

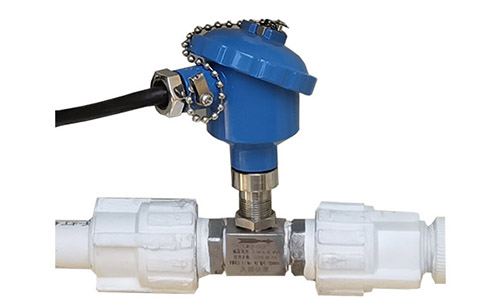

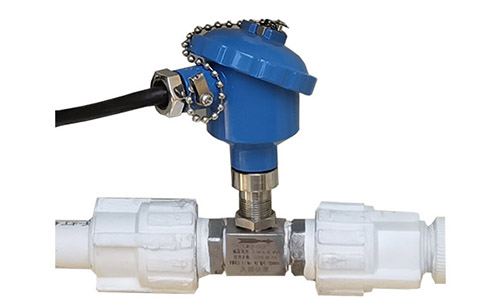

④ Flowmeter | To measure the water flow during the test, the IPX9K water flow is required to be 14-16L /min, and the IPX6K water flow is 75 ± 5L/min. |  |

⑤ Water tank | The water tank is the water storage device of the test chamber, which provides water source for the water jetting test. |  |

⑥ Pressure sensor | The actual water pressure is measured and the data is transmitted to the control system. |  |

⑦ Solenoid valve | Control water flow off. |  |

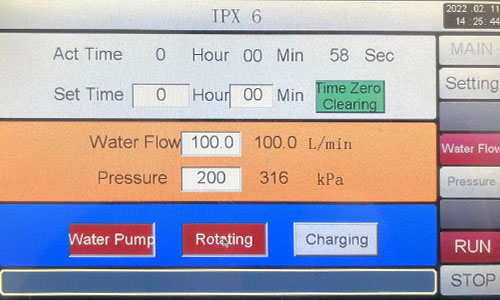

⑧ Control system | Touch screen intelligent control system, you can set the test parameters, such as spray pressure, test time, sample table speed. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español