Photovoltaic systems are widely used all over the world. To generate energy, PV modules are installed on the ground, in industrial buildings, private homes, charging stations, cars, and airplanes. This makes it even more important for these components to function perfectly in all climates. With the rapid rise of the photovoltaic industry today, the quality and reliability of photovoltaic modules have become key factors in determining their market competitiveness and long-term performance. In order to ensure that photovoltaic modules can operate stably in a variety of harsh environments, pv environmental chambers play a vital role.

Ⅰ.The background and importance of pv environmental chamber

With the growing global demand for clean energy, the photovoltaic industry has ushered in unprecedented development opportunities. However, photovoltaic modules are faced with complex and changeable environmental conditions in practical applications, such as extreme temperature changes, high humidity, strong winds, sand and dust, etc. These factors may lead to the deterioration of component performance, aging of packaging materials, circuit failures and other problems, thereby shortening the service life of components and reducing power generation efficiency.

In order to evaluate the tolerance and performance stability of photovoltaic modules in different environments in advance, the test chamber has become an essential testing equipment. By simulating various harsh environmental conditions, strict testing of photovoltaic modules can effectively screen out products with reliable quality, and provide guarantee for the long-term stable operation of photovoltaic power stations.

Ⅱ. Three tests performed in pv environment chamber

PV environmental chamber meets the test index

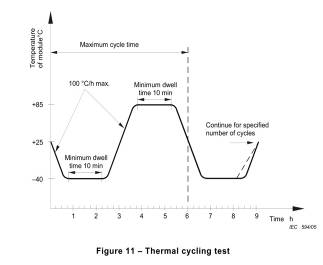

1. Thermal cycling test:

In the test space with wind speed of not less than 2m-S-1, the temperature cycles between -4O0C±2℃ and 85℃+2'C, the change rate between high and low temperature does not exceed 100C/H and remains stable for at least 10min at each extreme temperature, and each cycle time does not exceed 6 hours.

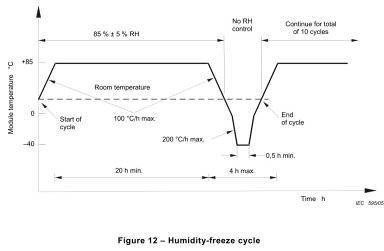

2. Humidity - freeze test:

Put the photovoltaic module into the pv environmental chamber at room temperature, so that its inclination is not less than 5 degrees with the horizontal plane. Close the door and complete 10 cycles as shown in the picture below. And the temperature should be within ±2C of the set value, and the relative humidity should be maintained within ±5%R-H of the set value at all temperatures above room temperature.

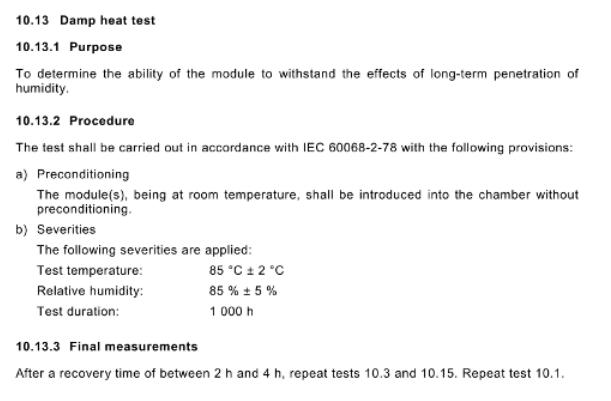

3. Damp - heat test

Put the photovoltaic module into the environmental test box at room temperature, so that its inclination is not less than 5 degrees with the horizontal plane. Close the door and test under the following harsh conditions: Test temperature :85 ° C ±2° C

Relative humidity :85% ± 5%

Ⅲ. The innovative design of the combined pv environmental chamber

The pv environmental chamber, which combines the high and low temperature cycle test chamber and the wet and hot test chamber, realizes the simulation of a variety of complex environmental conditions in the same equipment. Its innovative design is mainly reflected in the following aspects:

1. Control system

Using advanced intelligent control system, it can accurately control the temperature, humidity change curve and cycle mode. For example, you can set up a high and low temperature cycle and then switch to a hot and humid environment at a specific temperature point to achieve a seamless complex test flow.

2. Air duct design

The optimized air duct structure ensures the uniformity of temperature and humidity distribution in the box, so that the environmental impact of each part of the photovoltaic module is consistent during the test. The temperature uniformity can be controlled within ±2℃, and the humidity uniformity within ±5%RH.

3. Heat insulation seal

Good thermal insulation and sealing performance, reduce heat and moisture leakage, improve energy efficiency, reduce operating costs.

4. Observe the window

Equipped with a large size observation window, it is convenient to observe the appearance changes of photovoltaic modules in real time during the test process, without affecting the test environment.

Ⅳ. The performance advantages of the combined test chamber

(1) Performance advantages

1. Efficient and energy saving

The use of advanced cooling and heating technology, as well as optimized insulation structure, compared to the traditional separate test chamber, energy consumption is reduced.

2. Precise control

Advanced sensors and controllers ensure industry-leading temperature and humidity control accuracy, improving the accuracy and repeatability of test results.

3. Respond quickly

When the temperature and humidity change, it can quickly reach the set value, reduce the test waiting time, and improve the test efficiency.

4. Strong compatibility

It can adapt to different specifications and types of photovoltaic modules to meet diverse test needs.

Ⅴ . Conclusion

The high and low temperature cycle test will further test the thermal expansion and contraction characteristics of photovoltaic modules, the weatherability of packaging materials and the solid reliability of electrical connections. A prolonged, continuous test of a component's moisture resistance, potential corrosion, and electrical stability and tendency to change in wet environments. Wet freezing test is of great significance to photovoltaic modules. It assesses weather resistance and package reliability, verifies electrical performance stability, exposes defects in advance, improves product quality, and helps it comply with industry standards to ensure that components can adapt to complex environments for long-term stable operation. pv environmental chamber, as the core equipment to ensure quality in the photovoltaic industry, plays an irreplaceable important role in the research and development, production, quality testing and other key links of photovoltaic modules. At the same time, when using the test chamber, it is necessary to strictly follow the standard operating procedures and maintenance specifications to ensure the accuracy and reliability of the test results.