A thermal shock chamber is used to test a product's ability to withstand extremely high and low temperature environments and to quickly observe the chemical or physical changes caused by the thermal expansion and contraction of the test sample.

To meet different market demands, thermal shock test chambers can be categorized into the following three types based on the temperature shock method used:

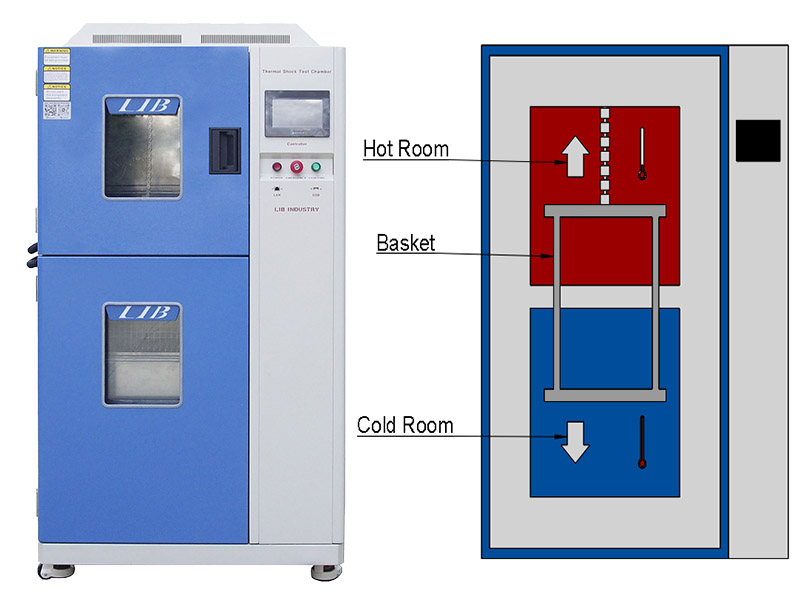

Two-zones method: The thermal shock test chamber is divided into two parts: the high temperature chamber and the low temperature chamber, which are connected through the hanging basket or track and other devices in the middle, so as to transfer the sample quickly. The LIB two-zones thermal shock test chamber hanging basket can move to achieve the temperature conversion within three seconds. The temperature of the high temperature chamber can reach +220℃, and the low temperature chamber can reach -75℃.

Test method: The sample is first subjected to a high temperature environment in a high temperature chamber for a certain period of time, such as at 150 ° C for 1 hour, and then quickly transferred to a low temperature chamber, placed in a low temperature environment of -40 ° C for 1 hour, so that it can withstand drastic temperature changes from high to low temperature in a short time, and vice versa.

For example, the chip test of electronic products, after running in a high temperature environment for a period of time, immediately enter a low temperature environment, can detect the stability of the chip when the temperature changes, to see whether there will be short circuit, open circuit or performance parameter drift and other problems. The temperature conversion time of the two-zones method is measured in seconds, and the temperature shock can be realized quickly, but the temperature change is more drastic and harsh.

Model | TS-162 | TS-340 | |

Internal Dimensions (mm) | 300*300*250 | 450*450*360 | |

Overall Dimension (mm) | 1560*870*1545 | 1710*1020*1845 | |

Interior Volume (mm) | 22L | 72L | |

Loading Capacity | 20kg | 30kg | |

Pre-heat Room | Upper limit Temperature | +220℃ | |

Heating Time | Ambient ~ + 200℃, within 30 minutes | ||

Pre-cool Room | Lower limit Temperature | -75℃ | |

Cooling time | Ambient ~ -70℃, within 30 minutes | ||

Test Room | High Temperature Exposure Range | Ambient +20 ~ +200°C | |

Low temperature Exposure Range | –65 ~ -5°C | ||

Temperature Fluctuation | ≤±0.5℃ | ||

Temperature Deviation | ≤±3 ℃ | ||

Temperature Recovery Time | Within 5 minutes | ||

| |||

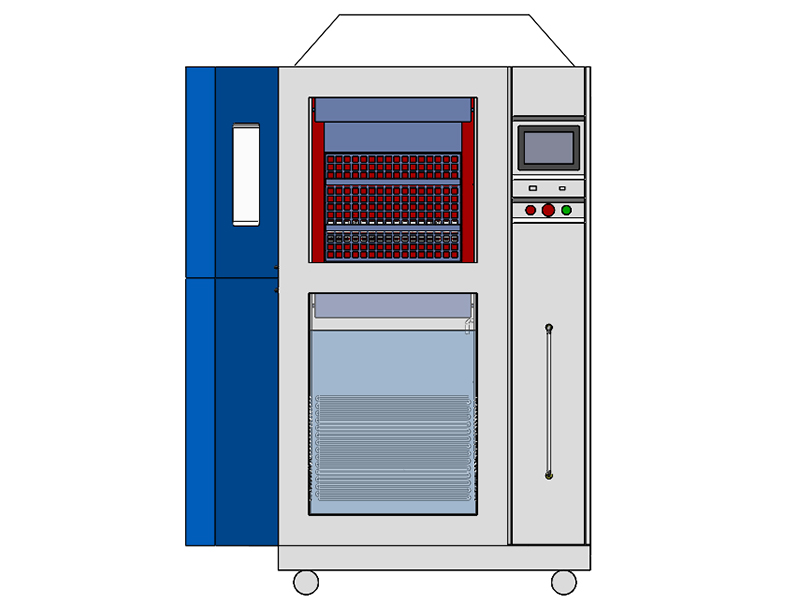

three-zones method: more refined than two-zones method. In addition to the high temperature and low temperature chambers, there is a normal temperature chamber as a transition, which circulates hot and cold air through pneumatic dampers on the left and right sides. The sample is kept still in the room temperature chamber, and the cold and hot air are circulated to realize the cold and hot shock test. Unlike the two-zones type, because the sample is static in the room temperature, the circulation of hot and cold air takes a certain time to raise or lower the temperature, so the temperature change of the sample is not so drastic and harsh. Its temperature curve is relatively flat.

.jpg)

Model | 3TS-100 | 3TS-210 | ||

Internal Dimension(mm) | 500*500*400 | 700*600*500 | ||

Overall Dimension(mm) | 1150*1950*2100 | 1350*2100*2200 | ||

Interior Capacity | 100L | 210L | ||

Loading capacity | 10KG | 15KG | ||

Pre-heat Room | Upper Limit Temperature | +220℃ | ||

Heating time | Ambient ~ +200℃,within 30 minutes | |||

Pre-cool Room | Lower Limit Temperature | - 70 ℃ | ||

Cooling time | Ambient ~ -70 ℃,within 30 minutes | |||

Test Room | High Temperature Exposure Range | Ambient + 20 ℃ ~ 200℃ | ||

Low Temperature Exposure Range | -65 ~ -5 ℃ | |||

Temperature Fluctuation | ≤±0.5℃ | |||

Temperature Deviation | ≤±3 ℃ | |||

Temperature recovery Time | Within 5 minutes | |||

| ||||

Liquid medium method: liquid at different temperatures is used as a heat transfer medium. The temperature of the high temperature liquid tank can reach +150℃, and the low temperature liquid tank can reach -80℃. After the sample is immersed in the high-temperature liquid for a period of time, such as 30 minutes, it is quickly transferred to the cryogenic liquid, where it is left for 30 minutes.

The advantage of this method is that the temperature transfer speed is fast, the uniformity is good, suitable for small and sensitive to temperature changes of the sample, like some precision small sensors, through the rapid thermal shock of the liquid medium, can quickly detect the change in its measurement accuracy when the temperature changes. However, the liquid medium method needs to consider the compatibility of the liquid and the cleanliness of the sample.

Different temperature shock methods have their advantages and disadvantages and their scope of application. In practical applications, appropriate thermal shock methods should be selected according to the characteristics of products or materials to be tested, industry standards and research purposes, so as to ensure the accuracy and effectiveness of test results and provide strong support for product quality improvement and material performance optimization.

LIB company's thermal shock test chamber, a complete range, two boxes, three boxes optional, hot and cold air impact, liquid to liquid impact, air to liquid impact, all kinds of impact test chamber can be customized to meet your various requirements for thermal shock test. Its precise temperature control system and efficient conversion device realize the rapid transfer of samples in different temperature zones, and high-quality thermal insulation materials not only save energy and reduce consumption, but also provide a stable environment for the test.

Choosing LIB thermal shock test chamber is to protect the quality of your products. Contact us now inquiry@libtestchamber.com , our team will give you the most professional solution and the best quotation.