Features and Benefits of IP6X Tester

1. The seal is good to ensure that dust will not leak into the external environment during the test, affecting the accuracy of the test results.

2. There is a circulating dust blowing device inside, which can evenly blow the dust to every corner of the tester to ensure a comprehensive test of the sample.

3. Strictly in accordance with the standard requirements of the parameters of the test, including the type of dust, concentration, airflow speed, etc., to ensure the reliability and comparability of the test results.

4. Modern intelligent control system, the operator only needs to set the test parameters, such as test time, dust concentration, pumping speed, etc., the device can automatically run and complete the test process.

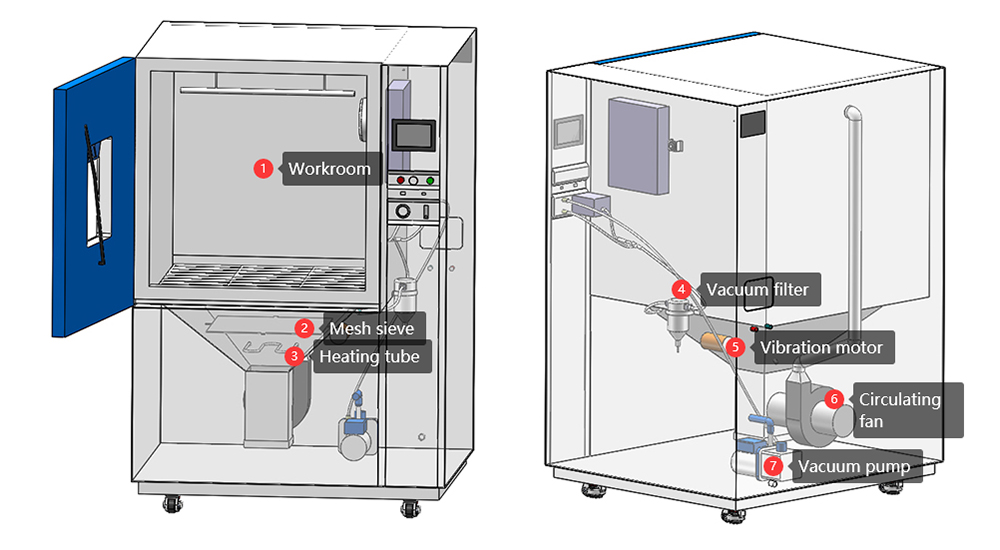

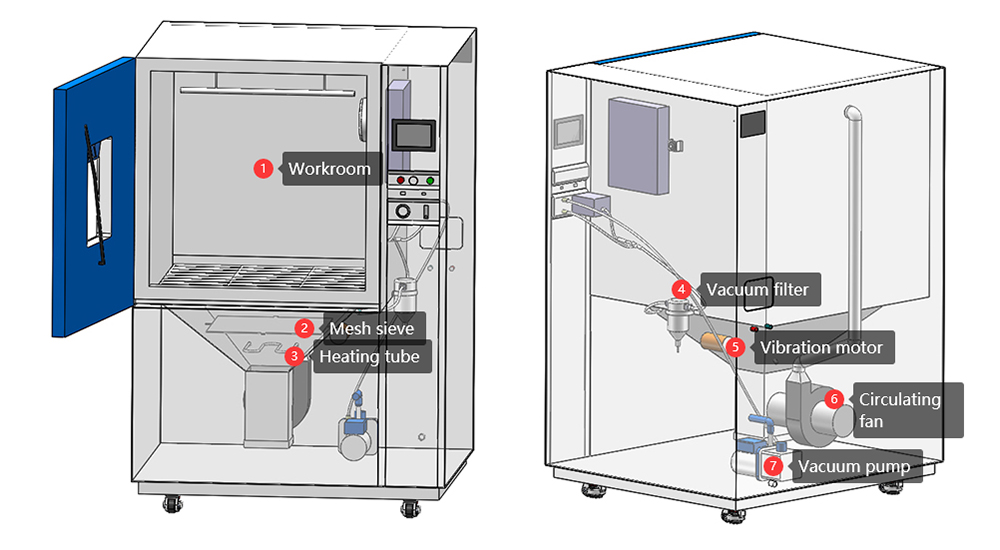

Configuration of IP6X Tester

① Workroom | The inner workroom is made of SUS 304 stainless steel, which can resist dust erosion under high wind speed. Equipped with LED lighting. Hanging sample holder and shelf type sample holder. The dust removal port is at the top of the studio and enters the test chamber through the action of gravity, which is combined with the air circulation system to form a dust circulation system.

|  |

② Mesh sieve |

The dust filtered by metal square hole is of specific specifications, the wire diameter is 50μm, the screen size is 75μm, the dosage is 2~4kg/m³, and the number of uses shall not exceed 20 times.

|  |

③ Heating tube |

Mainly used to prevent dust condensation during the test. It has safe and stable heating performance.

|  |

④ Vacuum filter |

In order to ensure the purity of the dust and the normal operation of the circulation system.

|  |

⑤ Vibration motor |

Shake away the dust that sticks to the inner walls of the workroom and funnel.

|  |

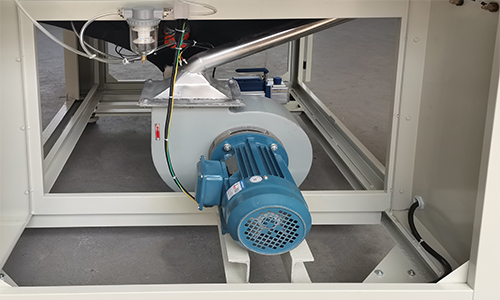

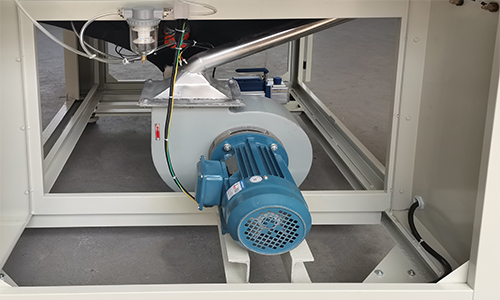

⑥ Circulating fan |

Closed alloy low noise motor provides power for dust cycle. |  |

⑦ Vacuum pump |

It simulates the air pressure difference that the product may encounter in actual use to simulate negative pressure, so as to test the dust resistance of the product more accurately. |  |

...................................................................................................................................................................................................................................................................

Features and Benefits of IPX5 Tester

1. Meet the IPX5 test requirements in IEC60529, simulate the low-pressure spray environment, the inner diameter of the nozzle nozzle is 6.3mm, the water flow rate is 12.5±0.625 (L/min), and the distance from the nozzle to the specimen is 2.5-3 meters.

2. The shell is made of steel plate, and the surface is painting treated, with good corrosion resistance; SUS 304 stainless steel is used in the inner workroom, which can withstand water erosion for a long time and is not easy to rust.

3. Equipped with automatic water circulation system and water filtration system. The studio has a drain, the test process is fully automatic, saving water. The filtration system can filter out impurities within 0.03MM to ensure the smooth spray.

4. Used for various types of product testing, such as outdoor lamps, household appliances, auto parts, electronic and electrical products, smart wearable devices, etc.

Specifications of IPX5 Tester

Model | R6K-1200 |

Internal Dimensions (mm) | 1000*1200*1000 D*W*H |

Overall Dimensions (mm) | 1150*3550*2100 D*W*H |

Interior Volume (L) | 1200 |

Parameter | Testing Platform Diameters | 600mm |

Testing Platform Speed | 5±1 r.p.m |

Turntable loads | 50kgs |

Testing Platform Height | 200-400 mm (adjustable) |

IPX6K | Internal Diameter of Nozzle | 6.3mm |

Water Flow Rate | 75 L/min +/- 5% |

Water pressure | 1000 Kpa |

Distance from Water Spraying to Specimens | between 2.5 m and 3 m. |

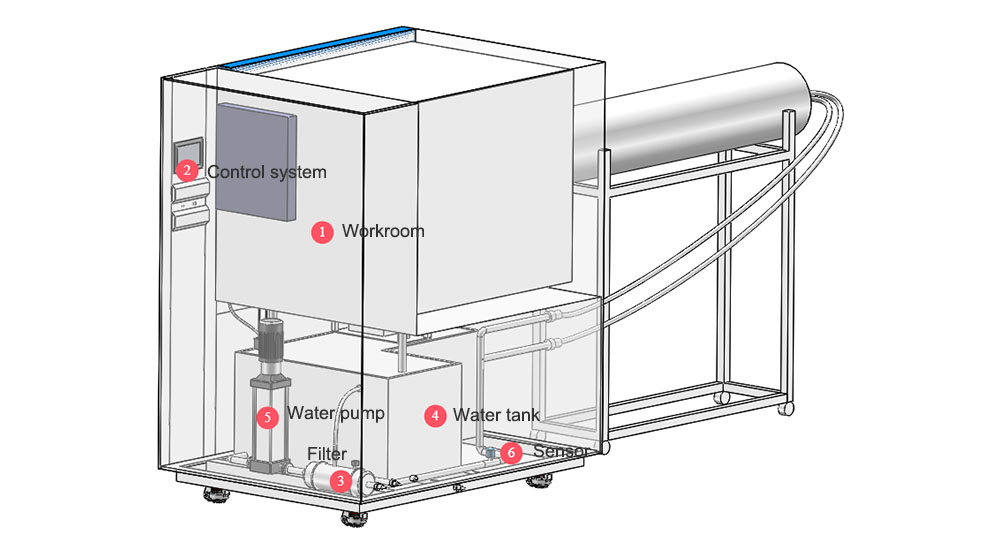

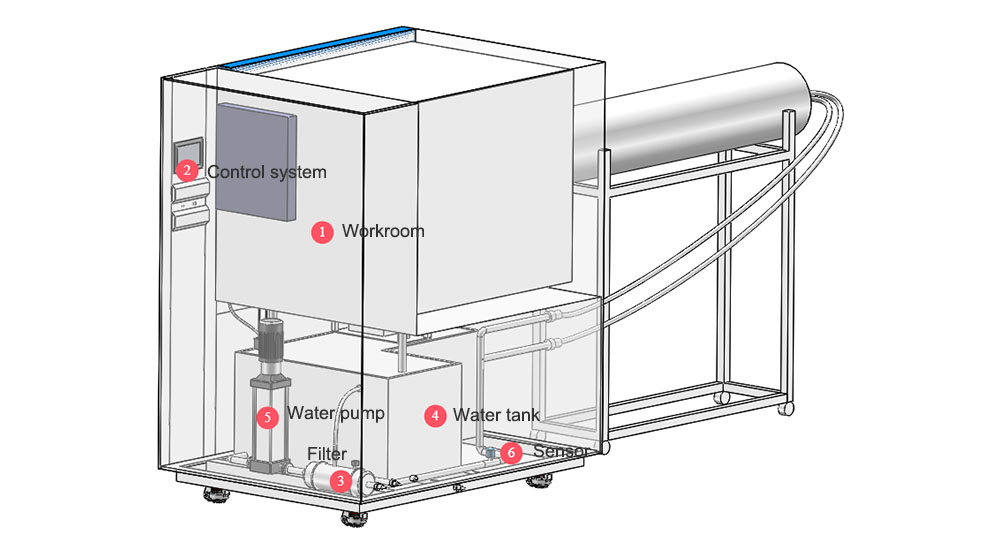

Configuration of IPX5 Tester

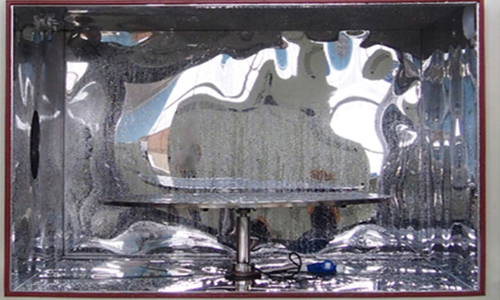

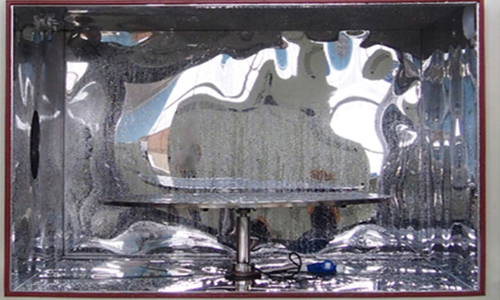

① Workroom | The workroom is made of SUS 304 stainless steel, which has good rust resistance and water resistance. The nozzle is on the left side of the workroom, with an inner diameter of 6.3mm and made of stainless steel, which has good corrosion and wear resistance and can guarantee long-term use. Turntable speed adjustable, height adjustable, equipped with waterproof power supply. Equipped with lighting and large viewing window.

|

|

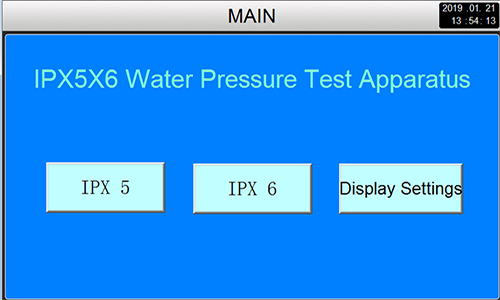

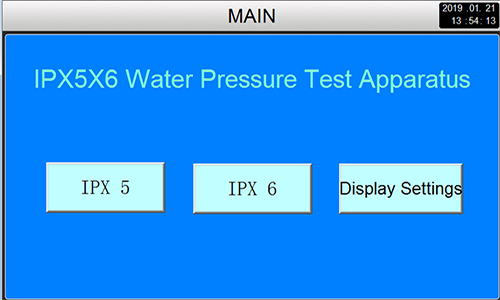

② Control system | Color programmable touch screen, the control interface can set the test time, spray pressure, flow and other parameters, and real-time display of the test process data. |  |

③ Filter | Automatic inlet filter, can filter out 0.03mm of impurities, to ensure the smooth spray. |  |

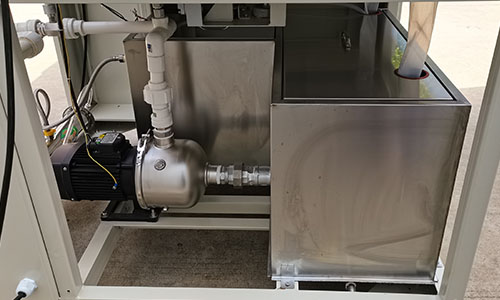

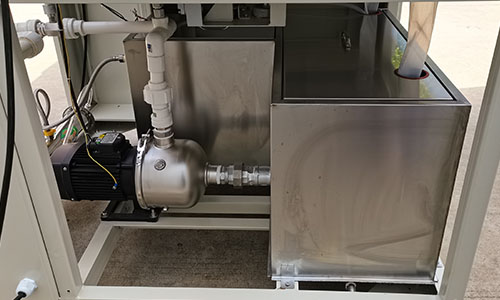

④ Water tank | SUS 304 stainless steel, rust and corrosion resistant, and low water level monitoring to prevent water pump dry turn damage. |  |

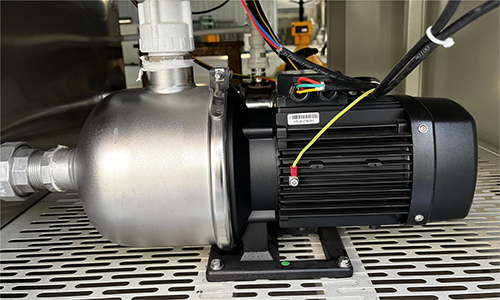

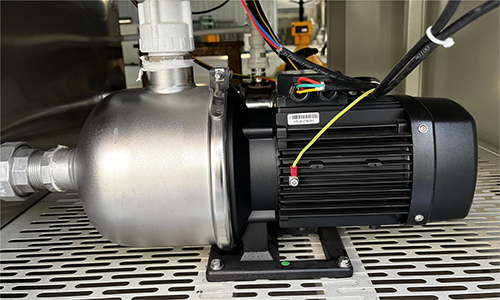

⑤ Water pump | The pump needs to transport water from the storage tank to the nozzle to meet the requirements of the IPX5 test for water flow and pressure. |  |

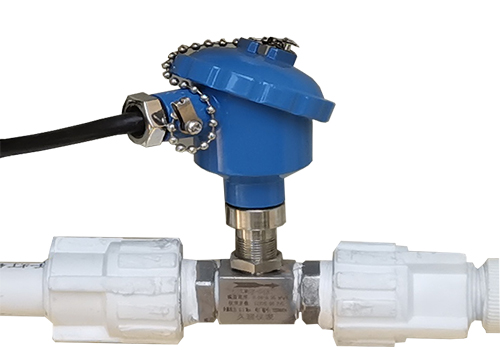

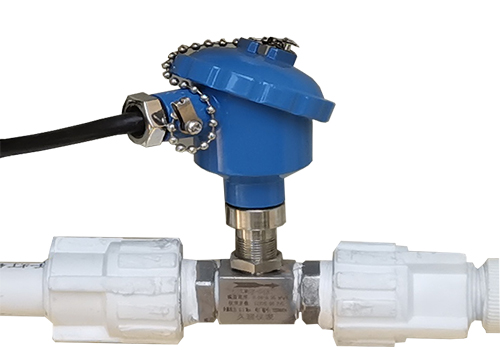

⑥ Sensor | The measuring range of the pressure probe is about 0-0.25MPa, real-time monitoring of the spray pressure to ensure that the water flow pressure in the test process meets the pressure requirements of the water flow specified in the IPX5 standard. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español