Features and Benefits of Thermal Cycle Testing Chamber

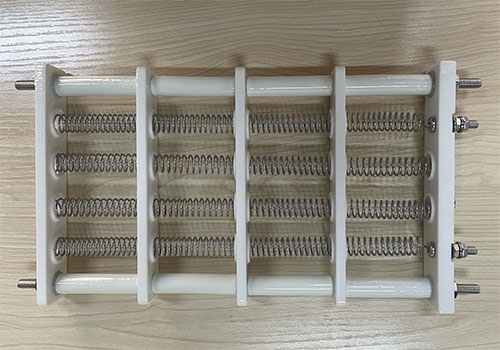

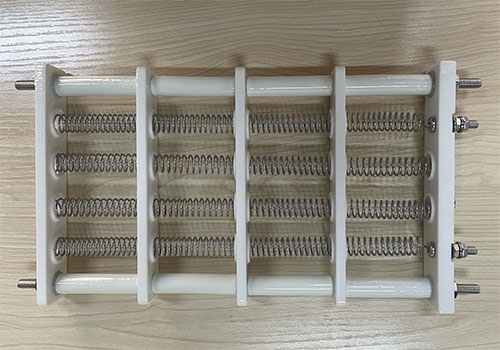

The heating system uses nickel chromium gold wire electric heater, the heating speed is fast, and the temperature can be quickly raised to the set high temperature value.

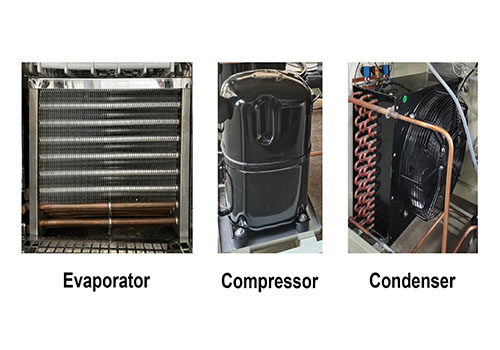

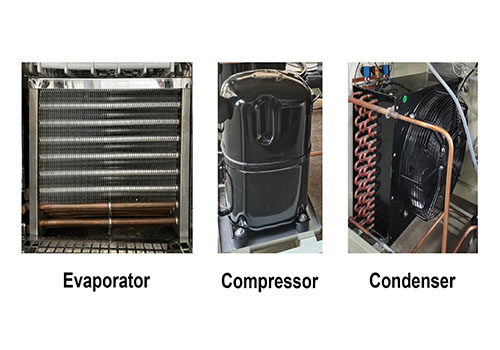

TECUMSEH refrigeration compressors and the use of cascade air cooling refrigeration system, R404A (high temperature cycle) and R23 (low temperature cycle) to improve the refrigeration efficiency and cooling speed.

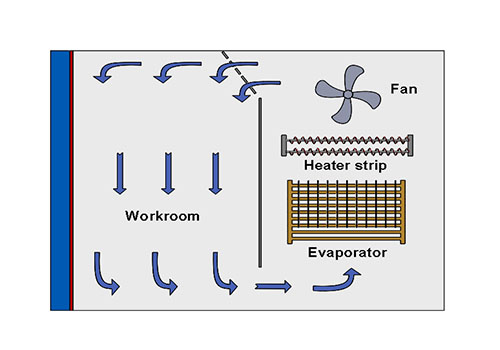

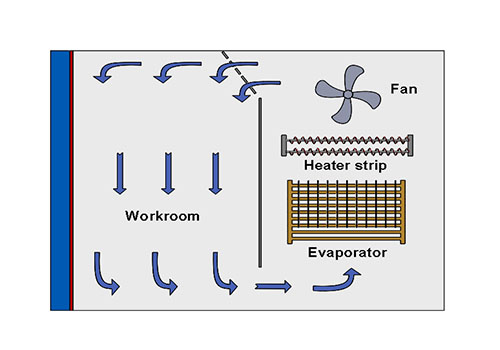

Air circulation system,air fan is located in the back of workroom, the air in the workroom can fully flow to ensure that the temperature uniformity of each corner, and the temperature deviation is within ±0.5 ° C.

PT-100 Class A temperature sensor, accuracy at 0.001 degrees. temperature sensor, real-time and accurate monitoring of temperature changes is fed back to the control system.

The chamber body of LIB Industry thermal cycle testing chamber is made of 4mm A3 steel panel with 2mm protective coating and SUS 304 stainless steel respectively for exterior and interior material.

Specifications of Thermal Cycle Testing Chamber

Model | TR5-100 | TR5-225 | TR5-500 | TR5-800 | TR5-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 800*1000*1000 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1300*1540*2120 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 800L | 1000L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Cooling Rate | 5 ℃ / min |

Heating Rate | 5 ℃ / min |

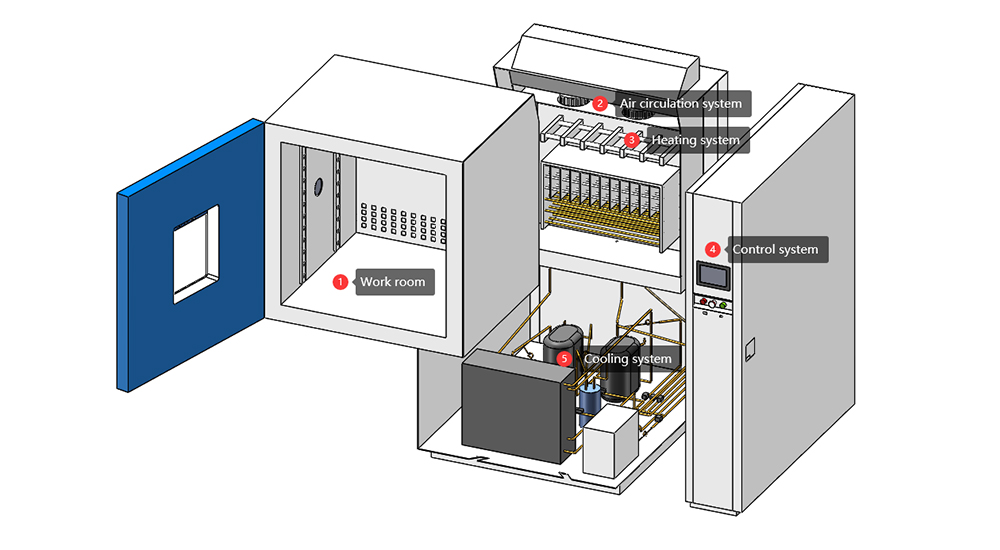

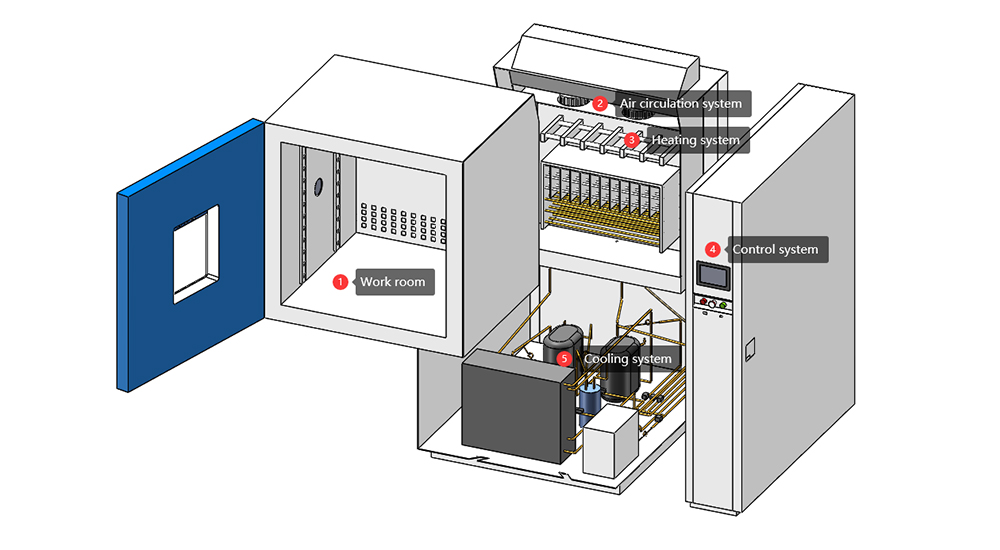

Configuration of Thermal Cycle Testing Chamber

The air circulation system, workroom, control system, refrigeration system and heating system in the rapid temperature change test chamber are interrelated and interact with each other to ensure the normal operation of the test chamber and the accurate conduct of the test.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español