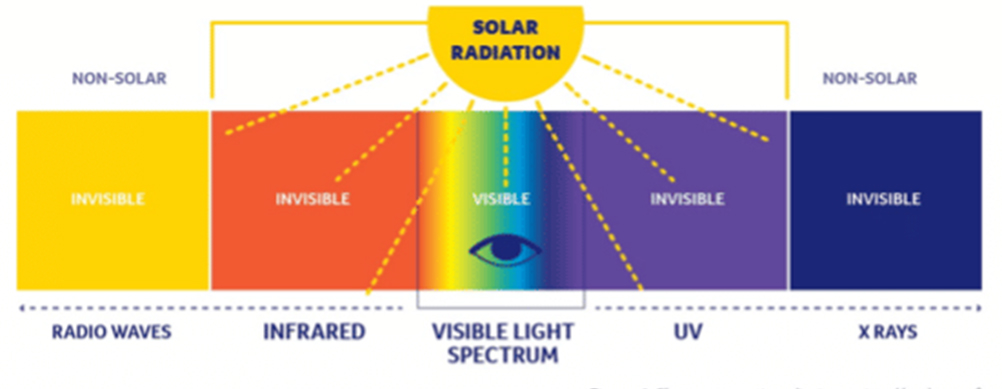

Sunlight is one of the main factors leading to the aging of materials. Ultraviolet, visible light and infrared rays destroy the chemical structure of the material, resulting in surface color fading, brittleness, yellowing, cracking and other phenomena. The effect of ultraviolet light is particularly obvious because it has a high energy, which is easy to trigger chemical reactions and accelerate the aging of materials.

UV aging is the abbreviation of Ultraviolet (ultraviolet), which is usually used to evaluate the speed of product aging under ultraviolet light. UV weathering tester can simulate this destructive environment. Sun irradiation aging is the main aging damage to outdoor materials. For indoor materials, It will also be subjected to a certain degree of solar radiation aging or aging caused by ultraviolet light in artificial light sources (such as ultraviolet lamps, ultraviolet bands in fluorescent lamps, etc.).

Wavelength: 320-400 nm, also known as long-wave blackspot effect ultraviolet rays. It has strong penetration ability and can penetrate most transparent glass and plastic. More than 98% of the long-wave ultraviolet rays in sunlight can penetrate the ozone layer and clouds to reach the Earth's surface.

Wavelength: 280-320 nm, also known as medium-wave erythema effect ultraviolet rays. It has moderate penetration ability, and its shorter wavelengths are absorbed by transparent glass. Most of the medium-wave ultraviolet rays in sunlight are absorbed by the ozone layer, with only less than 2% reaching the Earth's surface, especially strong in summer and early afternoon.

Wavelength: 200-275 nm, also known as short-wave germicidal ultraviolet rays. Its penetration ability is the weakest and cannot penetrate most transparent glass and plastic. Almost all of the short-wave ultraviolet rays in sunlight are absorbed by the ozone layer. Ultraviolet germicidal lamps emit UVC short-wave ultraviolet rays.

Wavelength: 100-200 nm, also known as vacuum ultraviolet rays.The longer the wavelength, the lower the energy. The radiation energy can cause the molecular bonds within the material to break, resulting in the material showing signs of aging such as decreased gloss, powdering, and breaking.

By installing different types of lamps, the uv aging test equipment can achieve irradiation in different bands.

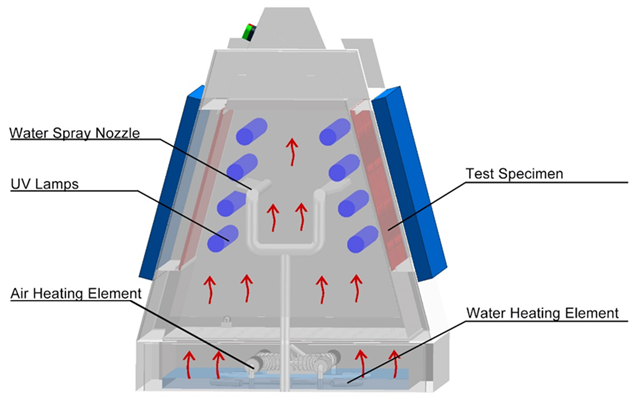

Besides the UV portion of sunlight, temperature and humidity are also important factors to consider. High temperatures can cause increased molecular movement within materials, leading to chemical reactions, thermal expansion, material softening, and other phenomena. Over time, the performance of materials exposed to high temperatures will gradually deteriorate.

High humidity can increase the interaction between materials and water molecules, in the form of rain, dew, and humidity, which can cause erosion, thermal shock, and other effects on materials. At the same time, moisture can also accelerate chemical reactions within materials.

Both of these factors can be achieved in the uv aging test equipment, and multiple factors such as temperature and humidity and UV light create a more complex and realistic test environment

UV weathering tester can set three aging modes: light, condensation and spray. Under the UV test chamber, there are heating components, including air heating components to control the temperature, and water heating components. When water is heated, a large amount of mist can be generated to simulate a high humidity environment. Near the UV lamp, nozzles are also provided on both sides to spray the test components. At the same time, the temperature in the working room can be controlled to adjust the humidity.

The scope of application of UV weathering tester is quite extensive, mainly including but not limited to the following materials and products:

such as plastics, rubbers, fabrics, etc. These materials are used outdoors and exposed to sunlight for a long time, which will accelerate aging due to ultraviolet radiation.

such as paints, coatings, dyes, etc. These materials may be affected by ultraviolet radiation when used outdoors or indoors, causing changes in their performance.

The outer shell, interior trim parts, and tires of a car all need to pass UV aging testing to ensure stability and durability during use.

Packaging materials such as paper, plastic film, etc., may also be exposed to ultraviolet radiation during storage and transportation, thus affecting their service life.

Building materials such as roofing materials, windows, etc., will be exposed to strong ultraviolet radiation when exposed to the outdoors for a long time, so UV aging tests are needed to evaluate their weatherability.

With UV aging testing, manufacturers can identify problems in product design and material selection in time for improvement and optimization. At the same time, this kind of testing can also help manufacturers predict the service life of products, and provide strong support for product quality control and after-sales service. Therefore, UV aging test has important application value in product development, quality control and after-sales service.

The above is the introduction of UV weathering tester, if you want to know more information, click here to view the more details.

If you need professional help and solutions, please contact us inquiry@libtestchamber.com , professional team is online to provide you with tailor-made solutions.