Large Environmental Chamber Features and Benefits

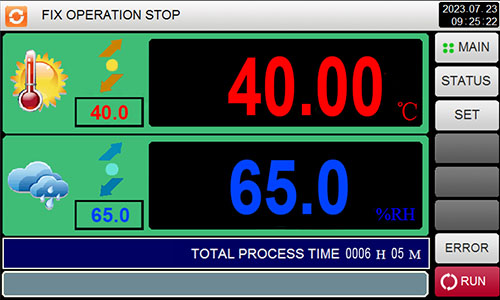

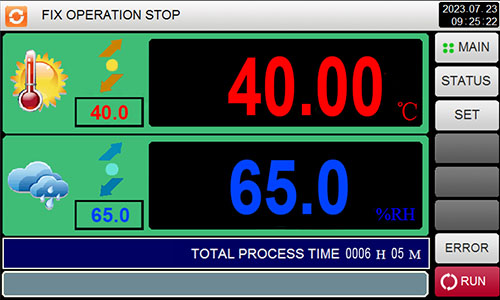

1. Temperature control accuracy can reach ±0.5℃, humidity control accuracy can reach ±2%RH, so as to truly simulate a variety of complex natural environment and specific working environment.

2. The internal space is large enough to accommodate a larger volume and a larger number of test samples, and can carry out overall testing of large electronic equipment, auto parts and other components.

3. In addition to temperature and humidity control, it can also customize a variety of environmental functions such as lighting, rain, dust, gas, etc., to meet the test needs of different products.

4. Simulate a variety of harsh environments that the product may experience in a short time, greatly improving the detection efficiency.

Large Environmental Chamber Specifications

Model | TH-100 | TH-225 | TH-500 | TH-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 1000L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

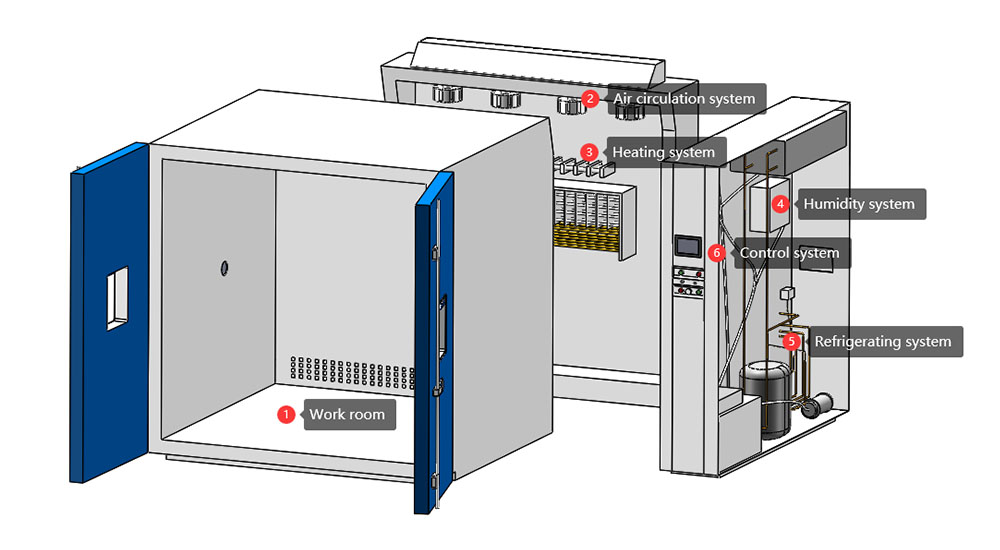

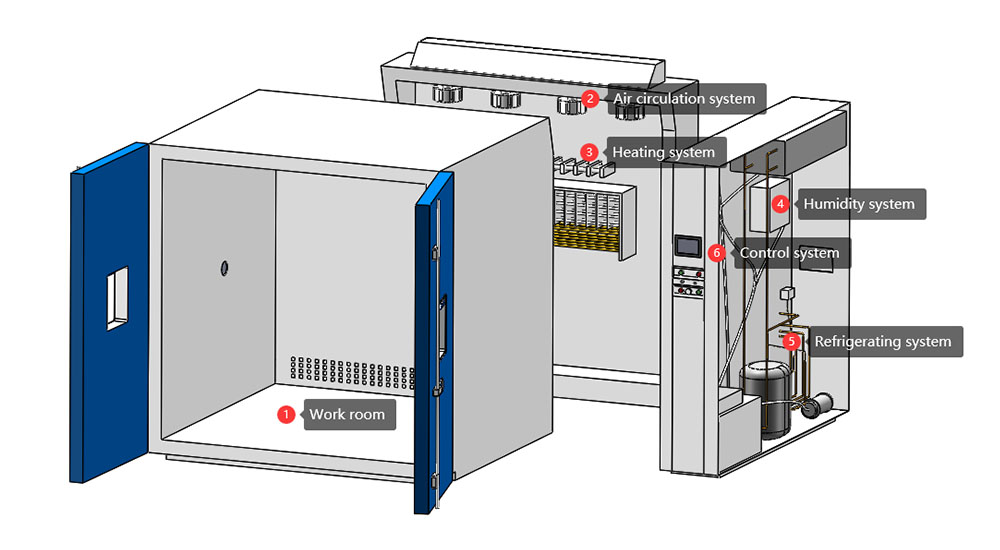

Configuration of Large Environmental Chamber

| 1. Workroom | SUS304 mirror stainless steel, high temperature and humidity resistance, corrosion resistance. Equipped with a high-precision temperature and humidity sensor. The large capacity of the workroom allows for the overall testing of the test pieces.

|

|

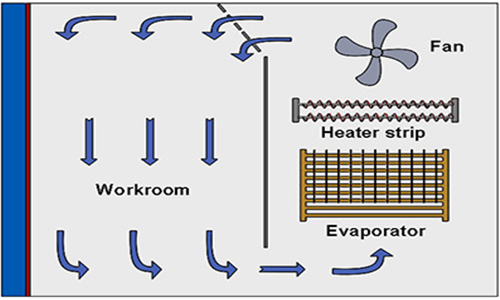

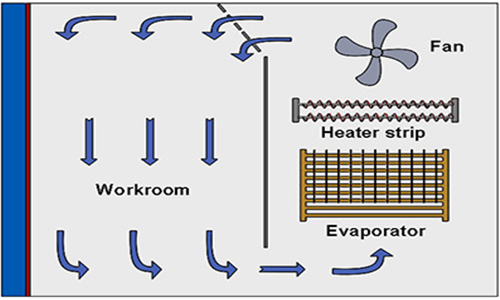

| 2. Air circulation system | Including fan and ventilation duct. The fan promotes the circulation of air in the chamber to ensure that the temperature and humidity are evenly distributed throughout the inner space. |  |

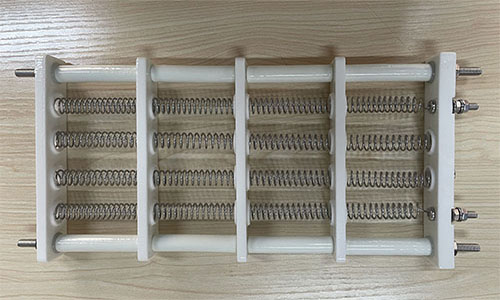

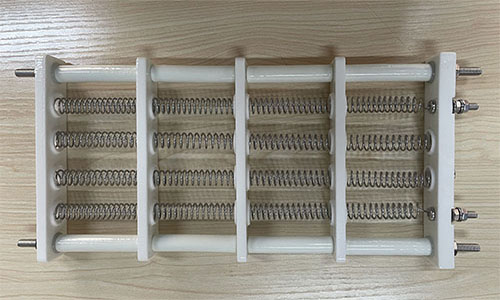

| 3. Heating system | Composed of heating wires, installed on the side of the workroom. |  |

| 4. Humidity system | Steam humidification is done by heating water to produce steam, which is then introduced into the workroom. |  |

| 5. Refrigerating system | Compressor refrigeration, including compressor, condenser, evaporator and other components. Through the circulation of refrigerant, heat is absorbed to achieve cooling. |  |

| 6. Control system | According to the set parameters and sensor feedback data, the controller can accurately control the heating, cooling, humidification and other systems. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español