The ozone test machine, as a precision equipment specially used to detect and evaluate the ozone resistance of products, is playing an indispensable role. So, what is the way to ensure the anti-ozone quality of the product? Now, let's delve deeper into the mystery.

The core working principle of the ozone test machine is to accurately simulate the ozone environment. It uses advanced technology to generate a specific concentration of ozone gas and places the product to be tested in this carefully regulated environment. After a specific period of continuous exposure, careful observation and evaluation of the product in terms of appearance, performance and other changes.

In the process of ensuring the anti-ozone quality of the product, the ozone test machine first demonstrated the excellent ability to accurately control the ozone concentration. You know, different types of products often need to be tested in different ozone concentration environments, only in this way, can truthfully reflect their true ozone resistance in practical applications. Typically, ozone test machines are able to reliably and accurately provide a wide range of ozone concentrations, from as low as a few parts per million (ppm) to as high as hundreds of ppm, according to preset parameters. For example, for the testing of certain rubber products, the initial ozone concentration may be set at 50 ppm, and then adjusted appropriately according to the test process and standard requirements.

The two key factors, temperature and humidity, also have a significant impact on the interaction effect of ozone with the product. The ozone test machine has the function of precise control of temperature and humidity at the same time, and can simulate various complex and changeable climate conditions with high fidelity. Taking common plastic products as an example, under the environment of 40 ° C and 65% relative humidity, the erosion effect of ozone will be significantly intensified. By testing in a variety of temperature and humidity combination scenarios, the ozone resistance of the product can be evaluated from a more comprehensive dimension, thus providing valuable data support for the actual use of the product in different regions and seasons around the world. The temperature control range of the LIB ozone test machine is from 0 ° C to 100 ° C, the humidity control range is between 30% and 98%RH, and the control accuracy can reach ±0.5 ° C and ±2%RH.

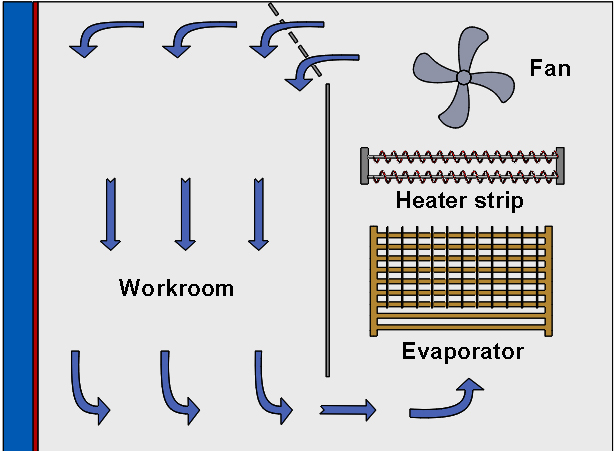

In addition to the fine control of environmental parameters, the ventilation and circulation system inside the test chamber is also an important part of ensuring accurate and reliable test results. A set of excellent performance of the ventilation system can effectively ensure the uniform distribution of ozone in the machine, to minimize the local concentration of too high or too low deviation, to ensure that all parts of the product can be balanced and consistent ozone action. The efficient circulation system helps to maintain a high degree of stability in the temperature and humidity inside the machine, effectively reducing fluctuations. Taking an advanced ozone test machine as an example, its ventilation volume can reach more than 3 times the volume of the chamber per hour, and the circulating wind speed can be stabilized between 1-2 m/s, which significantly improves the repeatability and reliability of the test.

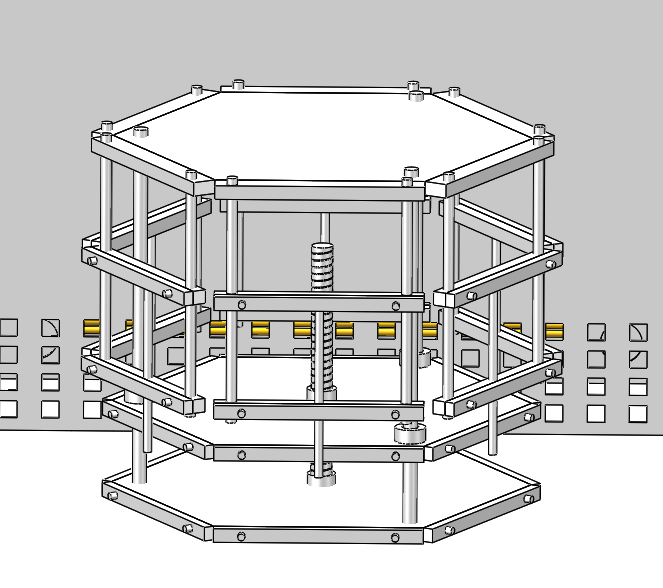

In the use of ozone test machine to carry out testing work, the installation and placement of samples also contains a lot of attention. In order to obtain more representative and accurate test results, the samples should be placed in an orderly manner in strict accordance with the prescribed spacing and specific direction, and resolutely avoid mutual occlusion and interference. At the same time, for different types and shapes of products, it is also necessary to carefully select suitable fixtures and support devices to ensure that the product can always be stably exposed to ozone during the entire test process. For example, for long strips of samples, special hooks or brackets may be used to ensure that they are suspended vertically and fully receive ozone.

The reasonable setting of the test time is also a key point related to the effectiveness of the test. Too short a test time may not fully expose the product's potential ozone resistance defects, while too long a test cycle may cause unnecessary resource consumption and excessive product aging. In general, the determination of the test time needs to take into account the type of product, the intended application area, and the strict requirements of the relevant standards. In the testing process, it is necessary to conduct rigorous observation and professional testing of the product in accordance with the established time interval, and record in detail the changes in its appearance color, trace changes in size, fluctuations in physical properties (such as hardness, tensile strength), and the evolution of chemical properties (such as composition changes) and other key indicators.

In addition, the ozone test machine is equipped with cutting-edge monitoring and control systems. Through high-precision sensors, the ozone concentration, temperature, humidity and other key parameters in the machine are monitored in real time, and the collected data is quickly transmitted to the intelligent control system for in-depth analysis and accurate processing. As soon as the parameters are perceived to deviate from the pre-set ideal value, the control system automatically activates the adjustment mechanism to ensure that the test conditions are always exactly in line with the preset requirements. At the same time, these valuable data will be stored properly, providing a solid data foundation for subsequent detailed analysis and professional report generation.

In order to ensure the accuracy and reliability of the test results, the ozone test machine needs to follow a strict cycle of calibration and careful maintenance. The calibration work focuses on the precision calibration of core components such as ozone concentration detectors and temperature and humidity sensors to ensure that their measurement accuracy perfectly meets the strict requirements of relevant standards. Maintenance work is widely involved in the deep cleaning of equipment, regular replacement of key components, timely lubrication of mechanical parts and other aspects, to ensure that the equipment can be long-term stable and efficient operation.

To sum up, the ozone test machine, as the core weapon to ensure the anti-ozone quality of products, provides enterprises with accurate, scientific and reliable test data through a series of rigorous and scientific means such as accurate regulation of environmental parameters, reasonable planning of sample installation and placement, accurate setting of test time, advanced monitoring and control technology and regular calibration and maintenance. Enterprises should attach great importance to and make full use of this advanced equipment, and continue to promote the optimization and upgrading of product quality, so as to steadily occupy an invincible position in the changeable market competition.