The JIS D0203 standard is a widely recognized Japanese industrial specification for rain testing, offering detailed guidance on rainfall intensity, droplet size, and water impact. It applies across industries including electronics, automotive components, aerospace equipment, and outdoor devices.

By adhering to this standard, manufacturers can reliably simulate real-world rain conditions, ensure consistent product quality, and confidently demonstrate waterproof performance to customers and regulatory bodies.

|

|

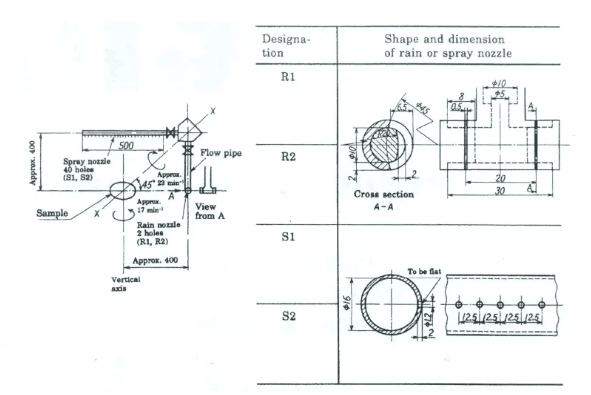

- Spray pipe inner diameter: 16 mm, length: 500 mm

- Spray hole diameter: φ1.2 mm, number: 40, spacing: 12.5 mm

- Adjustable spray flow: 1.9–3.2 L/min, spray pressure: 0.1–3 kg/cm²

- Rotating pipe axis: 45º, pendulum tube speed: 23 r/min

- Sample support rotation: 5 r/min, adjustable

- Water pressure: 0.1–3 kg/cm², spray flow: 24.5–39.2 L/min

- Spray nozzle meets R1/R2 specifications

- Rotating shaft angle: 45º, rotation speed: 23 r/min

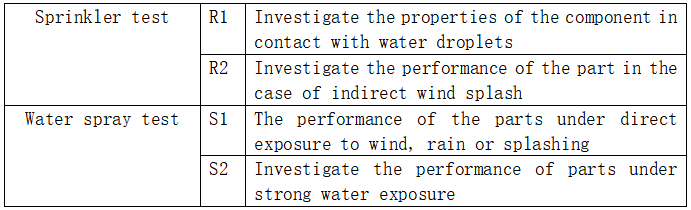

R1 Test | R2 Test | S1 Test | S2 Test | |

Water spray pressure | 0.3kgf/cm² (about 4.3psi) | 0.1kgf/cm² (about 1.4psi) | 1kgf/cm² (about 14.2 psi) | 3kgf/cm² (about 42.7 psi) |

Flow rate | 0.8 gal/min (about 3.2 L/min) | 0.5 gal/min (about 1.9 L/min) | 6.5 gallons/min (about 24.5L /min) | 10.3 gal/min (about 39.2 L/min) |

Test duration | 10 minutes | 10 minutes | 30 minutes | 60 minutes |

Nozzle | 2 | 2 | 40 | 40 |

The core principle of the JIS D0203 rain test chamber is to simulate the natural rainfall environment through a well-designed system to apply different intensity and form of rain impact to the product under test. The common ways of rain mainly include spraying and dripping rain.

Test method for moisture and water resistance of automotive parts in JIS D0203 standard:

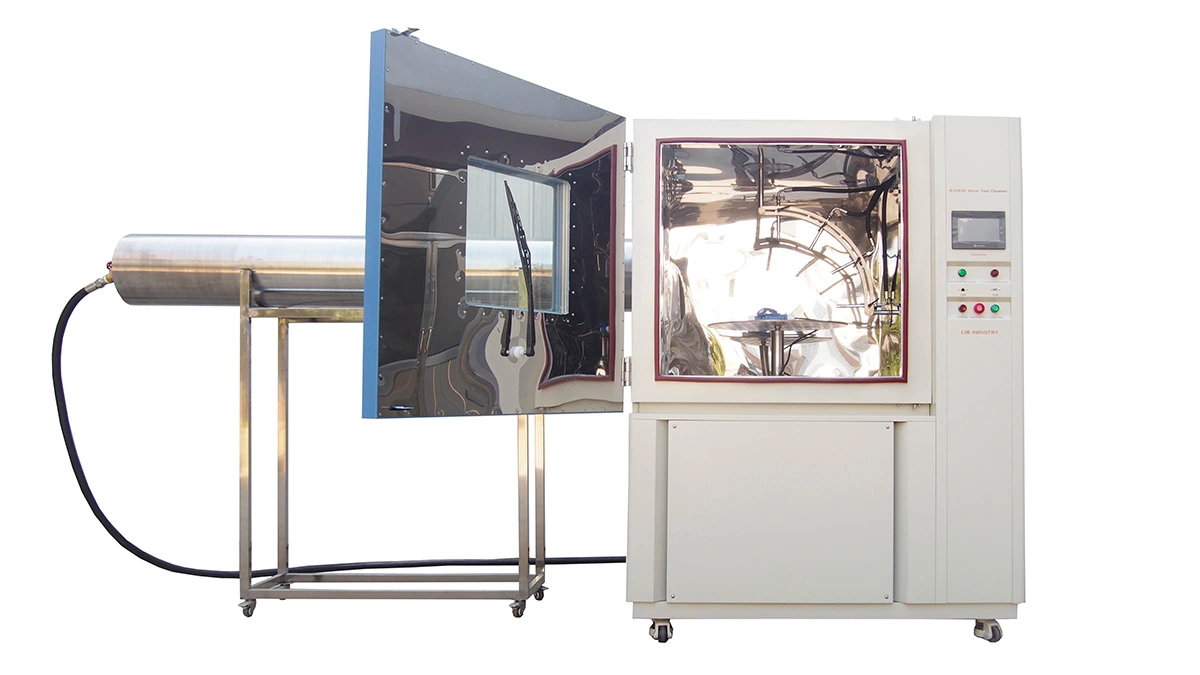

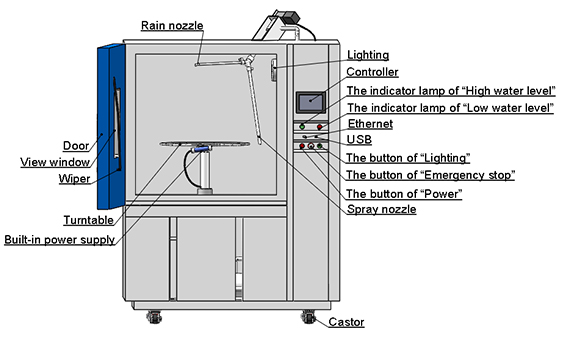

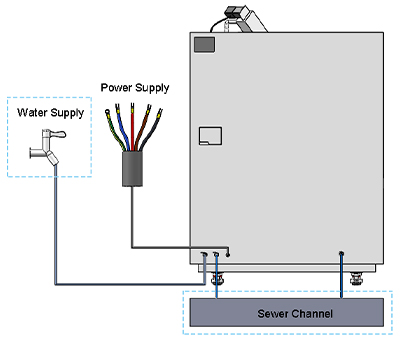

This waterproof test equipment is designed and manufactured according to the four test types of R1, R2, S1 and S2 in JIS D 0203-1994 "Test method for moisture and water resistance of automobile parts"

Equipped with high-sensitivity flow sensors and precision pressure valves, the system maintains rainfall intensity with exceptional accuracy. During heavy rain simulations, water pressure remains stable between 0.03–0.3 MPa, ensuring repeatable and reliable test results.

Integrated fans and wind regulation technology simulate wind speeds from 0–18 m/s with ±0.5 m/s accuracy. This replicates real-world conditions where wind alters droplet trajectory and impact, providing a comprehensive assessment of waterproof performance.

Evenly distributed nozzles, optimized chamber layout, and advanced sealing materials guarantee uniform rain coverage (±5%) and prevent leakage. This design ensures a controlled and stable testing environment, critical for accurate, reproducible results.

Customizable Sample Fixtures: Accommodates various product sizes and shapes.

Energy-Efficient Operation: Advanced water circulation and fan systems reduce energy consumption.

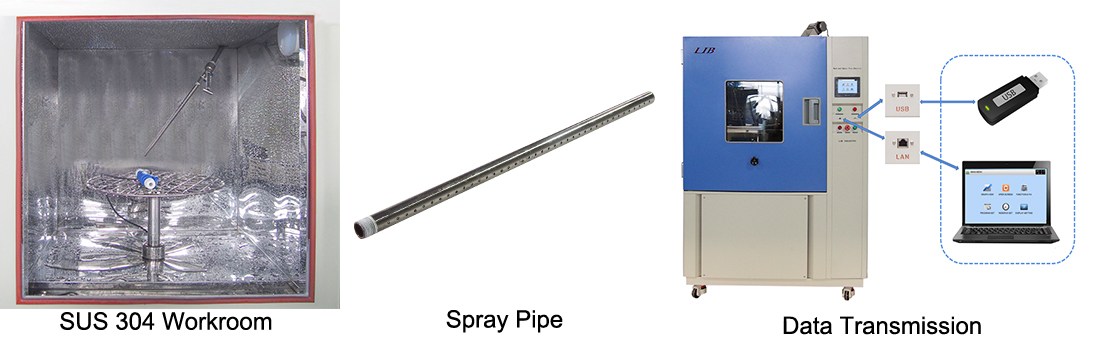

Remote Monitoring & Control: Supports networked control for real-time monitoring and data logging.

Compliance Assurance: Fully conforms to JIS D0203 requirements and supports documentation for certification purposes.

Durability & Reliability: Built with corrosion-resistant materials(SUS304 workroom) and robust construction(thickened A3 steel plate) for long-term, maintenance-friendly operation.

Model | R-1000JIS |

Interior Volume (L) | 1000 |

Distance from Specimen to Nozzle | Approx.400mm |

Rain Nozzle | 2 holes |

Rain Nozzle Hole | Φ0.5mm |

R1 Water Flow Rate | 1.9L/min. |

R2 Water Flow Rate | 3.3L/min. |

Spray Nozzle | 40 holes |

Spray Nozzle Hole | Φ1.2mm |

S1 Water Flow Rate | 24.5L/min |

S2 Water Flow Rate | 39.2L/min |

Water Pressure at Nozzle | 0.03 ~ 0.30MPA |

Turntable Rotation Speed | 17r/min |

| Water Pressure Control | Flow meter |

|  |

Industry | Test Objective | Simulation Condition |

Electronics | Smartphones, tablets, smart TVs | Heavy rain 5 mm/min for 30 min to verify device sealing and circuit protection |

Automotive | Car windows, lights, antennas | Rain combined with 80 km/h wind for 1 hour to assess component sealing and safety |

Aerospace | Aircraft shell, avionics | High-altitude rainfall at -50°C, 8 mm/min, 60 min to ensure operational reliability in extreme conditions |

Marketing Insight: By simulating real-world wet conditions across diverse industries, LIB industry’s JIS D0203 rain test chamber empowers companies to improve product durability, enhance safety, and gain a competitive edge

.

Precision Engineering: Adjustable rain intensity, droplet size, and wind speed ensure consistent and repeatable results.

Custom Configurations: Chambers tailored to your product size and testing requirements.

Rapid Support: Receive personalized quotations and preliminary test plans within 1–3 hours.

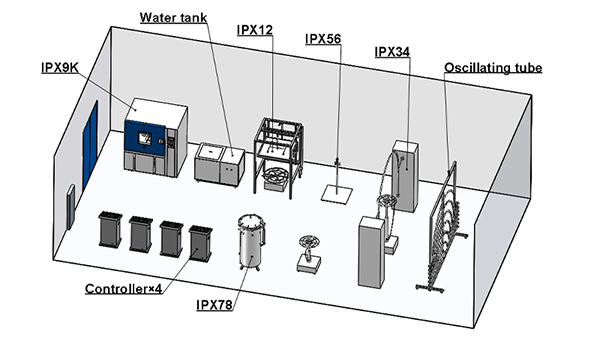

Lifetime Assistance: 3-year warranty and lifetime technical support, with comprehensive IPX testing solutions including IPX1–IPX6, IPX7,IPX8 and IPX9K, plus dust test chambers.

Customer Promise & Next Steps: LIB industry combines engineering excellence with responsive support to help you build a dedicated waterproof testing lab that meets your exact needs. Ensure your products perform reliably under real-world wet conditions. Contact LIB industry today inquiry@libtestchamber.com to design your lab, safeguard your product’s reputation, and demonstrate superior quality to your customers.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia