Thermal Humidity Chamber Features and Benefits

1. A variety of temperature and humidity change modes are supported, such as linear rise cooling/humidity, step jump cooling/humidity, etc., to meet different test requirements.

2. The use of high-quality insulation materials, reduce the loss of heat and humidity, reduce energy consumption and keep temperature and humidity stable.

3. Users can accurately set temperature, humidity, time and other parameters according to different test requirements to ensure the consistency and repeatability of test conditions.

4. It has overload protection, short circuit protection, pressure protection, etc., and also has fault self-diagnosis and alarm function to ensure the safety of equipment and personnel.

Thermal Humidity Chamber Specifications

Model | TH-100 | TH-225 | TH-500 | TH-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 1000L |

Heat load | 1000W |

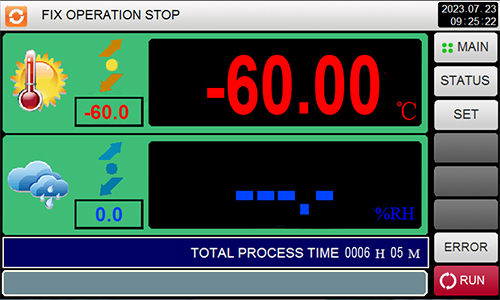

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

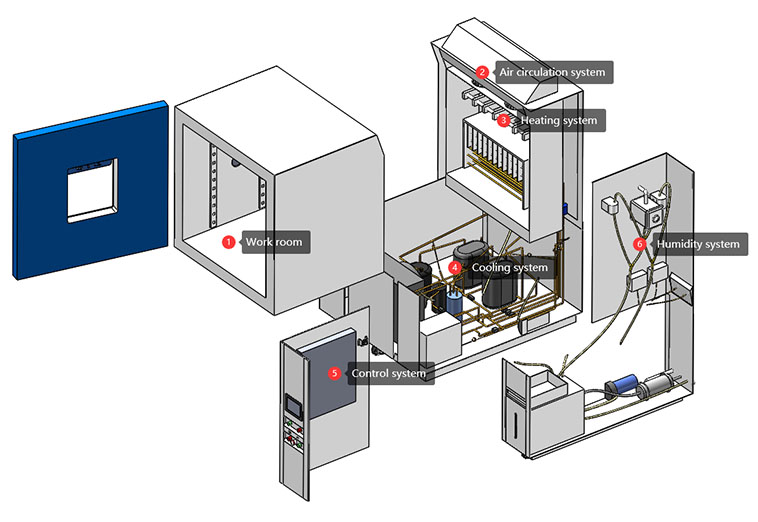

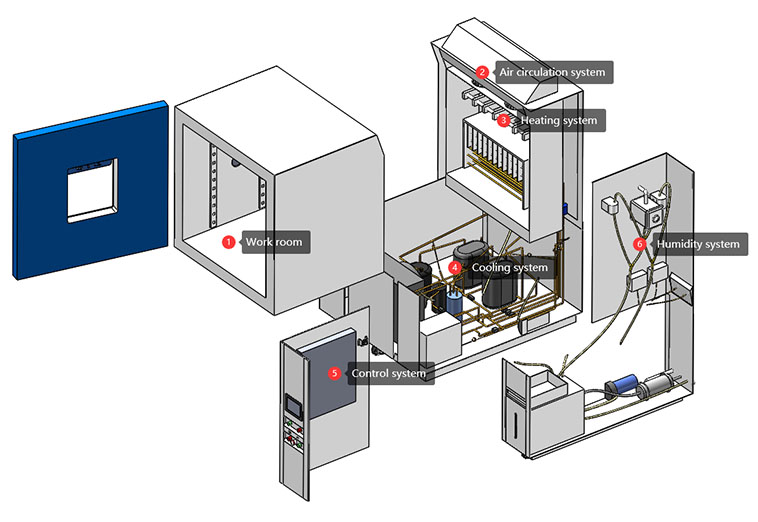

Configuration of Thermal Humidity Chamber

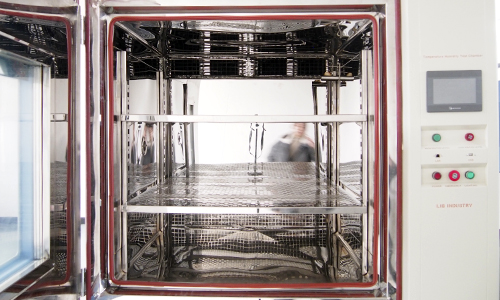

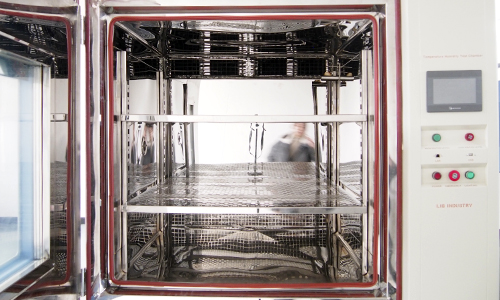

① Workroom |

Made of high-grade stainless steel (SUS304) mirror board, smooth surface is easy to clean, and strong corrosion resistance,

Observation window with a layer of hollow tempered glass, good heat insulation and anti-fog performance.

|  |

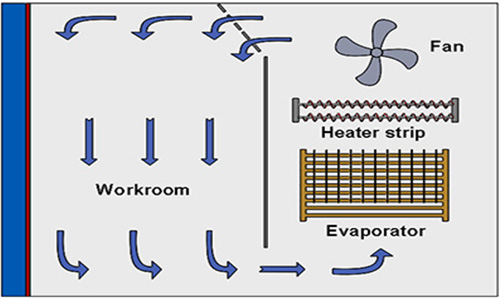

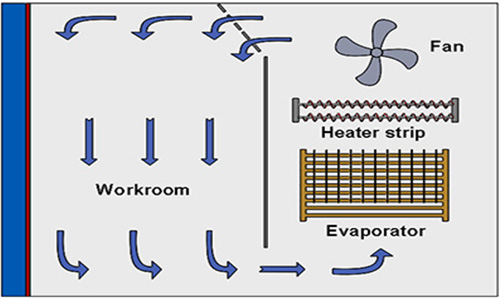

② Air circulation system

|

It is composed of temperature-resistant and low-noise air-conditioned motor and vane centrifugal wind turbine, etc., and ensures uniform distribution of temperature and humidity through forced convection.

|  |

③ Heating system | |  |

④ Cooling system | It is mainly composed of a compressor, a condenser, a throttling device (capillary) and an evaporator to form a refrigeration cycle. |  |

⑤ Humidity system | |  |

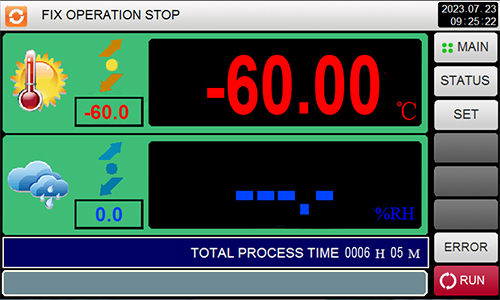

⑥ Control system | To achieve the precise control and monitoring of temperature and humidity, and with display, setting, programming and other functions. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español