Mini Thermal Chamber Features and Benefits

1. Compact design

Small size, benchtop structure, can be flexibly placed on a variety of work stations, do not take up too much space, especially suitable for limited space laboratory or workplace.

2. Precise temperature control and humidity control

As a type of temp and humidity chamber, Mini thermal chamber can accurately control the temperature, the temperature range is wide, can meet the strict requirements of different tests on the temperature. The low temperature of the test chamber is down to -70℃, and the high temperature can reach 150℃. With humidity adjustment function, mini thermal chamber can simulate different humidity environment, The low temperature of the test chamber can reach -70℃, and the high temperature can reach 150℃.

3. Cost effective

Compared with large test chambers, mini environmental test chamber’s price is more affordable, and it can meet most of the basic test needs, and the cost performance is outstanding. It is suitable for testing and detection in various fields, such as electronics, materials, biology, etc., and has high versatility.

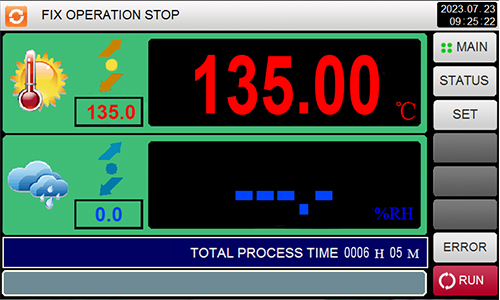

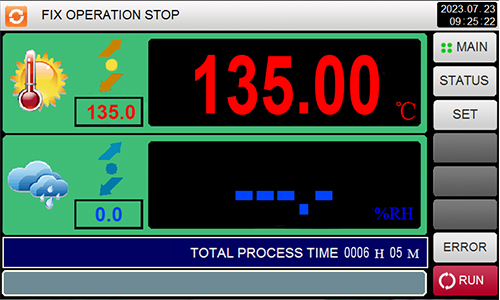

4. Operation interface

Mini thermal chamber is Equipped with intuitive and simple operation interface, PID programmable color touch screen controller, which can clear display, easy to understand parameter setting. Operators can create120 programs 100 segment. LIB also can preset program into the controller based on user testing requirements.

5. Excellent material

The exterior material is made of 4mm A3 steel panel with 2mm protective coating with good durability and corrosion resistance and high and low temperature resistance.

Mini Thermal Chamber Specifications

Model | T-50 | T-80 |

Internal Dimension (mm) | 320*350*450 | 400*400*500 |

Overall Dimension (mm) | 820*1160*950 | 900*1210*1000 |

Interior Volume | 50L | 80L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

Cooling system | Mechanical compression refrigeration system |

Controller | Programmable color LCD touch screen controller Ethernet connection |

Safety Device | Humidifier Dry-combustion protection; Over-temperature Protection; Over-current Protection; Refrigerant High-pressure protection; Water Shortage Protection; Earth leakage Protection |

Exterior Material | Steel Plate with protective coating |

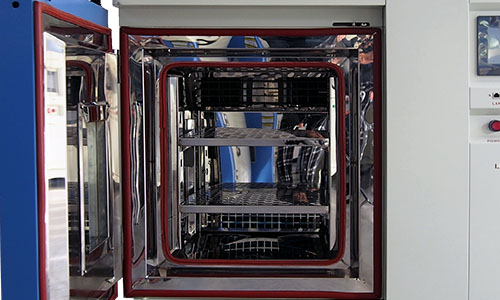

Interior Material | SUS304 stainless steel |

Thermal Insulation | Polyurethane foam and insulation cotton |

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing |

Standard Configuration | 1 Cable hole (Φ 50,) with plug; 2 shelves |

Weight | 190kgs | 220kgs |

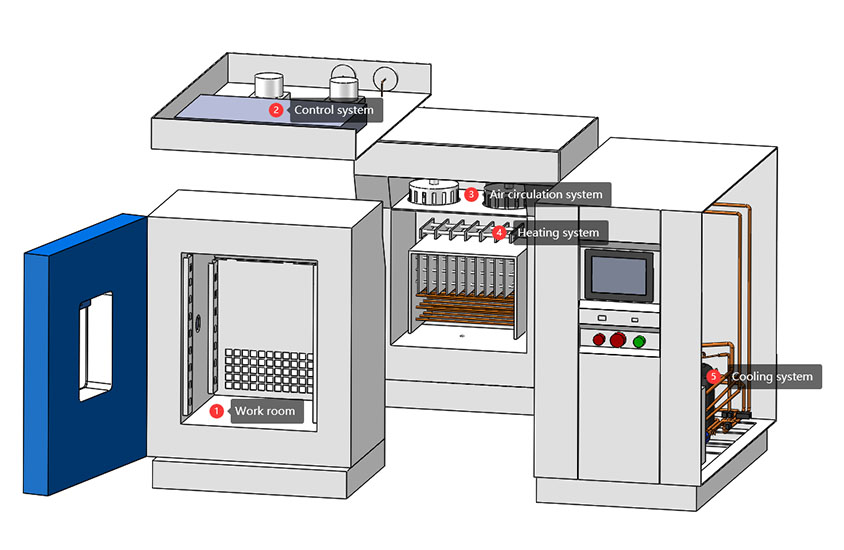

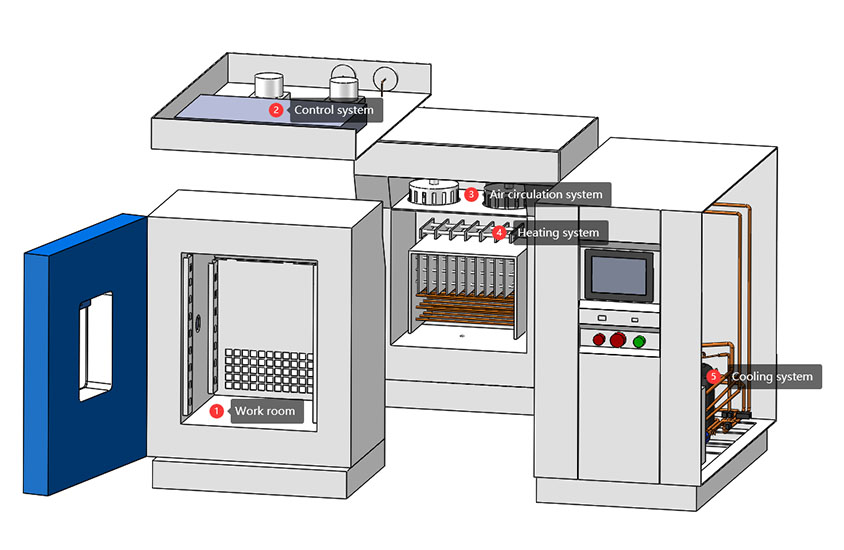

Configuration of Mini Thermal Chamber

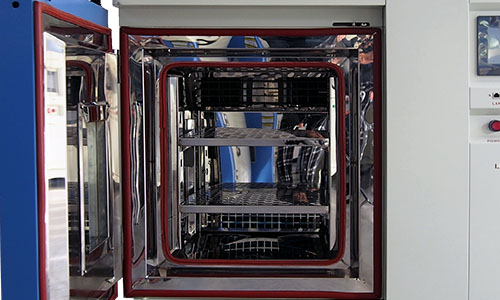

| 1. Workroom | 50L, 80L Made of SUS304 stainless steel and other corrosion-resistant, easy to clean materials. Standard double punch sample holder, bearing capacity 50KG.

|

|

| 2. Control system | set temperature, humidity and other parameters and test procedures, with the display of working status, record data and other functions, using PLC controller with touch screen operation, easy to operate, can achieve accurate control. |  |

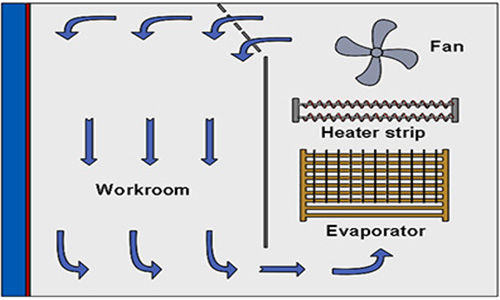

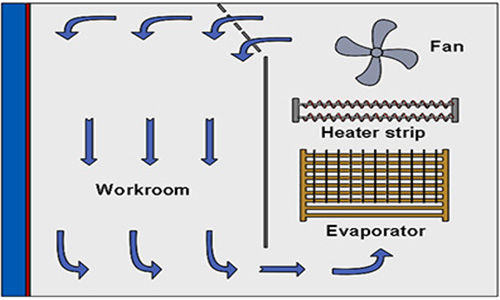

| 3. Air circulation system | Composed of fans, air ducts, etc., and the fans promote the circulation of air in the workroom, so that the temperature of the workroo is evenly distributed. |  |

| 4. Heating system | Composed of heating element such as heating wire and temperature sensor. Installed in the mezzanine, the electricity generates heat to raise the temperature of the workroom. |  |

| 5. Cooling system | It is composed of compressor, evaporator, condenser, expansion valve and other components. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español