Features and Benefits of Blowing Dust Test Chamber

Features and Benefits of Blowing Dust Test Chamber

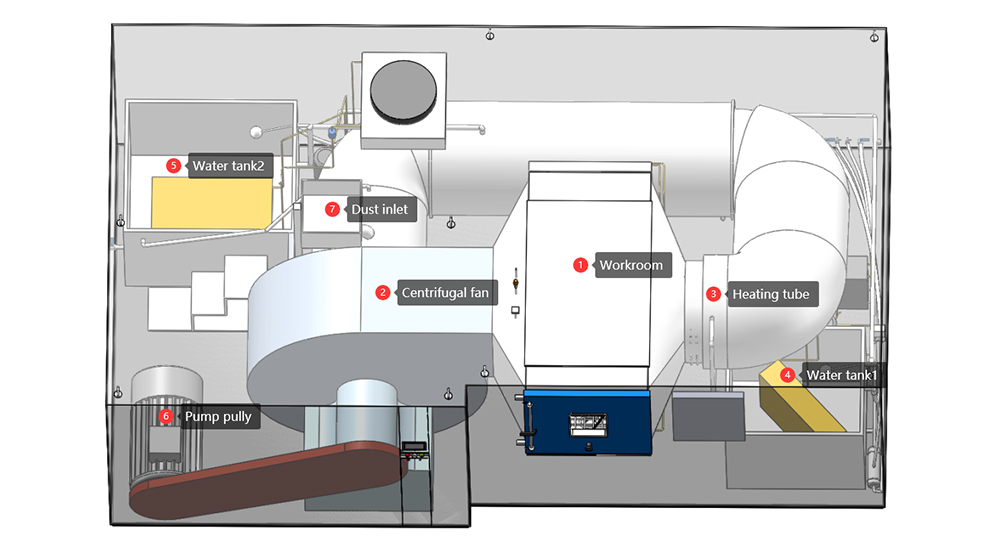

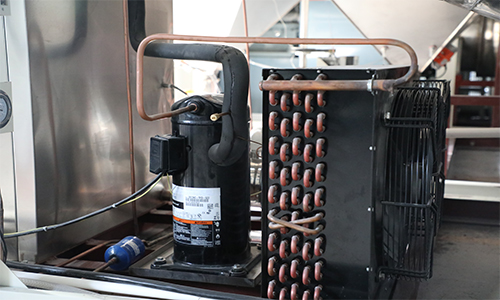

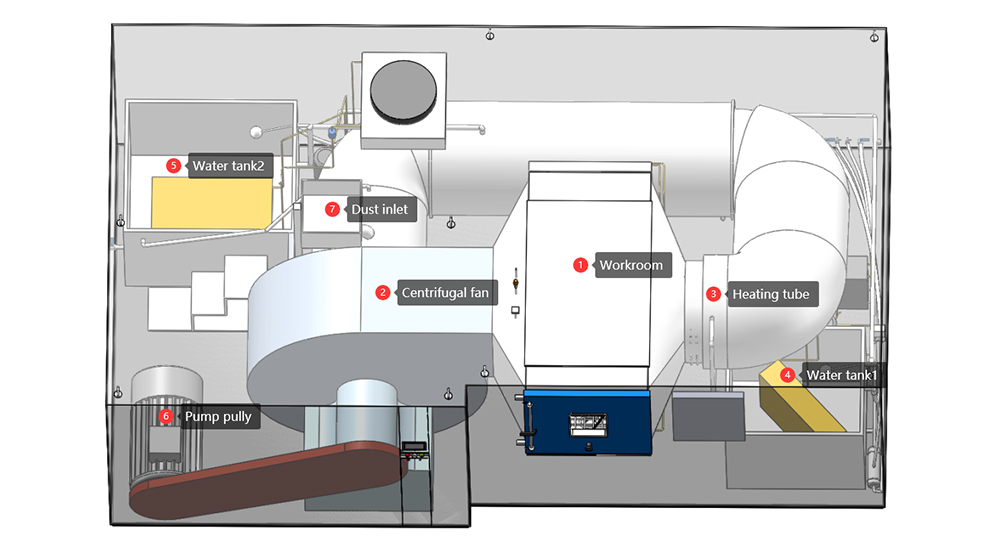

1. The workroom, air duct, etc., use strong and corrosion-resistant SUS304 to resist the wear and erosion of sand and dust, and choose high-quality double-layer rubber seals to prevent sand and dust leakage and ensure a stable dust environment inside the blowing dust test chamber.

2. Accurately control the amount and speed of dust injection. 10.7±7g/ m³ blowing dust and

0.18+0.2g/m³; 1.1+0.3g/m³; 2.2+0.5g/m³ blowing sand can be injected to simulate a variety of different dust environments.

3. The sand particles spin at high speed in the workshop and the pipeline, and friction with the inner wall of the pipeline to generate a lot of heat. Set up a tank outside the pipe to allow water to flow around the pipe and absorb the heat from the pipe.

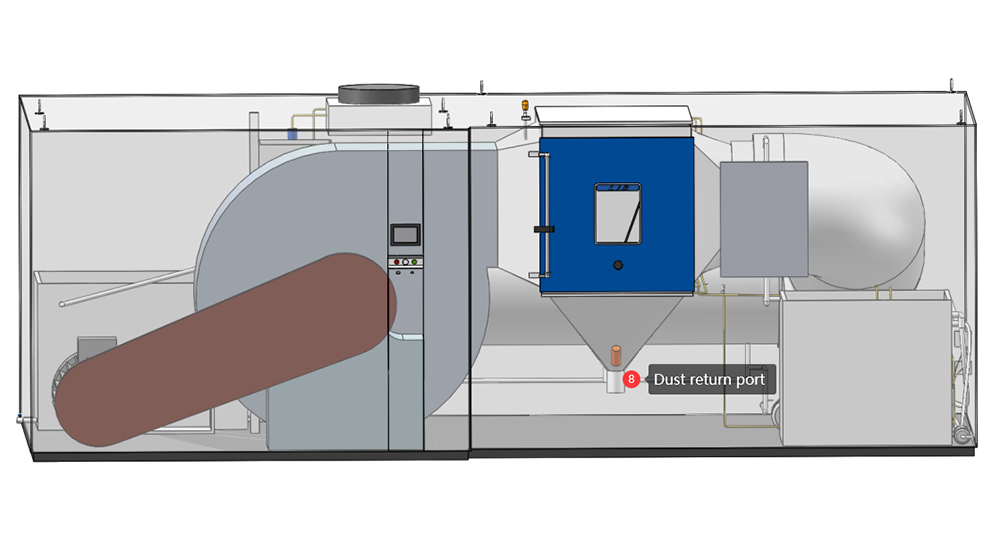

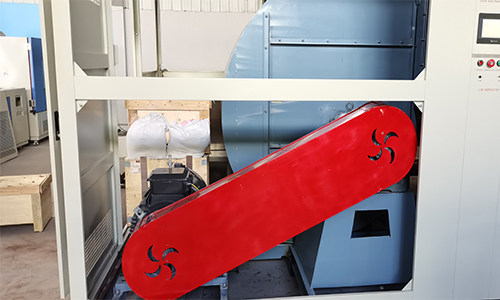

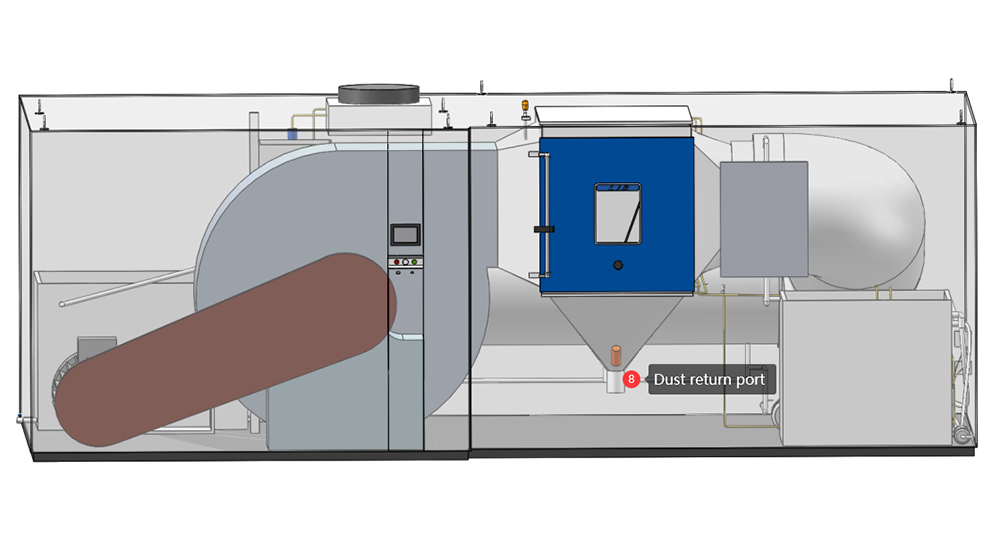

4. The dust cycle is to collect the falling dust through the bottom funnel-shaped structure, and after filtering through the mesh screen of the collection port, the fan is inhaled again and lifted to the upper space of the test chamber to achieve the repeated recycling of dust.

Specifications of Blowing Dust Test Chamber

Model | DIM-1000 |

Internal Dimension | 1000*1000*1000mm D*W*H |

Overall Dimension | 3000*6100*2200mm D*W*H |

Interior Volume | 1000L |

Blowing Dust |

Air velocity | 1.5 -8.9m/s |

Concentration of dust | 10.7±7g/ m³ |

Dust particles | < 150μm |

Blowing sand |

Air velocity | 18.0 -29.0m/s |

Concentration of sand | 0.18+0.2g/m³; 1.1+0.3g/m³; 2.2+0.5g/m³ |

Sand particles | 149μm - 600μm, 600μm - 850μm |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Testing Platform Diameter | 600mm |

Door Lock | Electromagnetic lock |

Testing Platform Speed | 1-7 r.p.m |

Dust Detector | Integrated dust detector |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Standard | MIL-STD- 810 |

Configuration of Blowing Dust Test Chamber

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español