The IP in the protection test refers neither to the patent nor to the network IP. In the definition of dust and water, the term IP stands for International Protection, and the following two numbers are the levels of protection established by the IEC 60529 standard.

These two numbers represent the protective capacity of "solid" and "liquid" respectively. The two digits after the IP, the first digit is the solid state protection level, that is, the dust level we are subjected to, the grade range is 0-6; The second number is the liquid protection level, that is, we often say that the waterproof level test, the grade division range is 0-8. So in fact, the IP56 waterproof test chamber is not accurate, and the IPX5X6 waterproof test chamber is more accurate.

level | Description | Waterproof protection level |

IPX0 | no waterproof | no waterproof ability and protection. |

IPX1 | drip-proof type (I) | the normal operation [stationary state] to prevent water droplets from entering, and can provide waterproof protection of 3 to 5 mm per minute of rainfall for 10 minutes |

IPX2 | drip proof type (II) | provides the same water protection as the IPX1, but passes four point water resistance tests up to 15 degrees. |

IPX3 | rainproof type | prevents water from entering, provides a flow rate of 10 liters per minute, and a flow pressure of 80~100KN/m2, and waterproof protection with 60 degrees of internal splashing for 5 minutes.

|

IPX4 | anti-splash type | prevents water from entering, which is equivalent to the waterproof protection ability of IPX3, but also passes the waterproof splash test at various angles. |

IPX5 | anti-jet type | provides a nozzle with a 6.3 cm opening at 3 meters away and shoots water pressure equivalent to 12.5 liters per minute and 30 kN /m2, which can resist the water column of the low-pressure spray gun for 3 minutes. |

IPX6 | wave proof type | provides a nozzle with a 12.5cm opening at a distance of 3 meters and shoots water pressure equivalent to 100 liters per minute and 100 kN /m2, which can resist the water column of the high-pressure spray gun for 3 minutes. |

IPX7 | intrusion resistant | provides water protection up to 1 meter underwater for 30 minutes. |

IPX8 | underwater model | provides water protection up to 1.5 meters underwater for 30 minutes. |

With the continuous progress of science and technology, the application scenarios of various electronic products, auto parts and communication equipment are more and more extensive, from indoor to outdoor, from dry environments to wet and even harsh climate conditions. In these different environments, the waterproof performance of the product is directly related to its reliability and service life. If the waterproof performance of the product is poor, it may lead to internal circuit short circuit, component damage and other problems, thus affecting the normal use of the product. Therefore, improving the waterproof performance of products is one of the key links to ensure product quality.

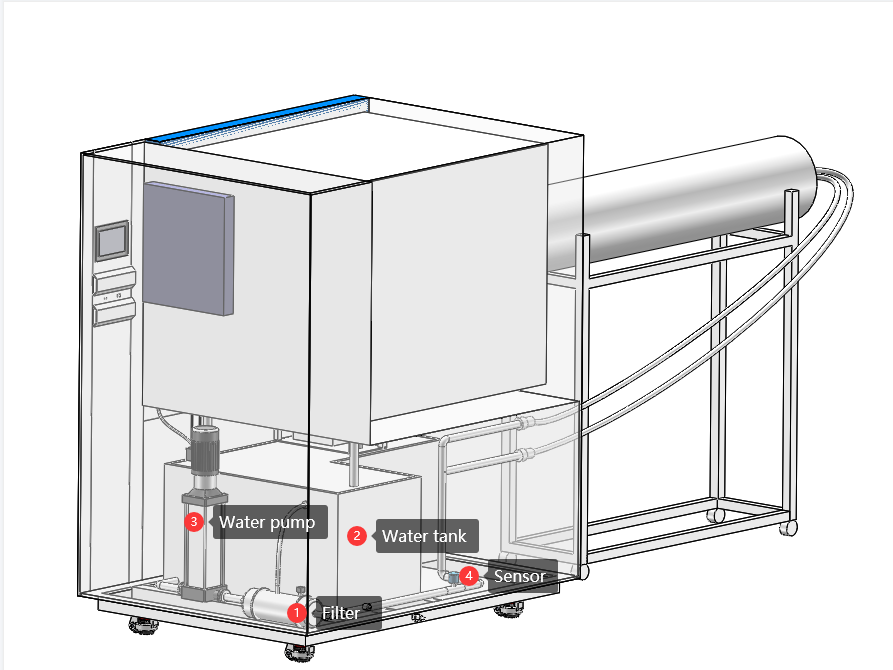

a. Equipment component 1:

IPX56 strong water spraying device

Functional parameters:

Suitable for IPX5, IPX6 testing of products;

Aperture: Phi 6.3mm (IPX5), Phi 12.5mm (IPX6);

IPX5, IPX6 nozzle threaded connection, quick replacement.

Water flow rate: 12.5±0.625L/min(IPX5), 100±5L/min(IPX6) Users set flow parameters on the touch screen, frequency conversion automatic adjustment mode;

Test time: Test time: 0-9999H59M can be set;

Nozzle distance from the shell: 2.5-3m;

Test pressure: IPX5 about 30KPa,IPX6 about 100KPa. (Note: test pressure is for reference only, subject to flow control);

b. Equipment components 2:

Tilting rotary stage

1. rotary table diameter: aboutΦ400mm;

2. turntable speed: 0-7 RPM, can be set;

3. the type of platform network tube;

4. sample power supply waterproof socket;

5. positive and negative rotation control, rotation action is controlled by the control cabinet;

6. drive: stepper motor + turbine reducer;

7. maximum load: 50KG.

c. Equipment components 3:

Intelligent water supply and control system

Functional parameters:

1. flow control: using high-precision turbine flowmeter and electronic digital flow meter intelligent control, using a set of water pump and a set of flow meter control, you can select and set the flow on the touch screen of the control cabinet.

2. the water tank is equipped with a liquid level switch, in the test can automatically fill water and low water level control pump stop protection function.

3. Human-machine interface

4. control function: flow control, load stage action control, test time control, handheld nozzle flow control, etc.

5. protection function: leakage protection, overload protection, short circuit protection, water shortage protection.

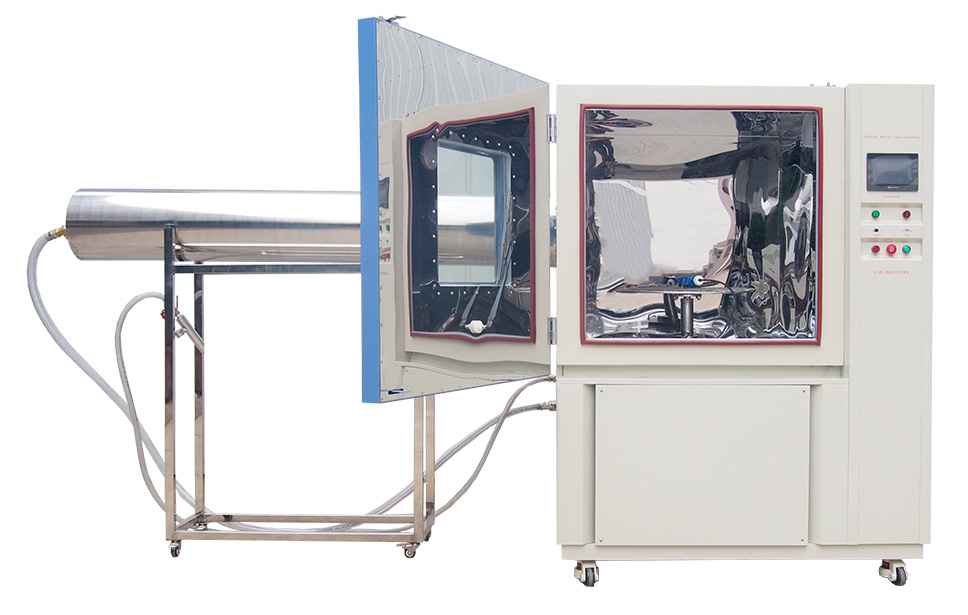

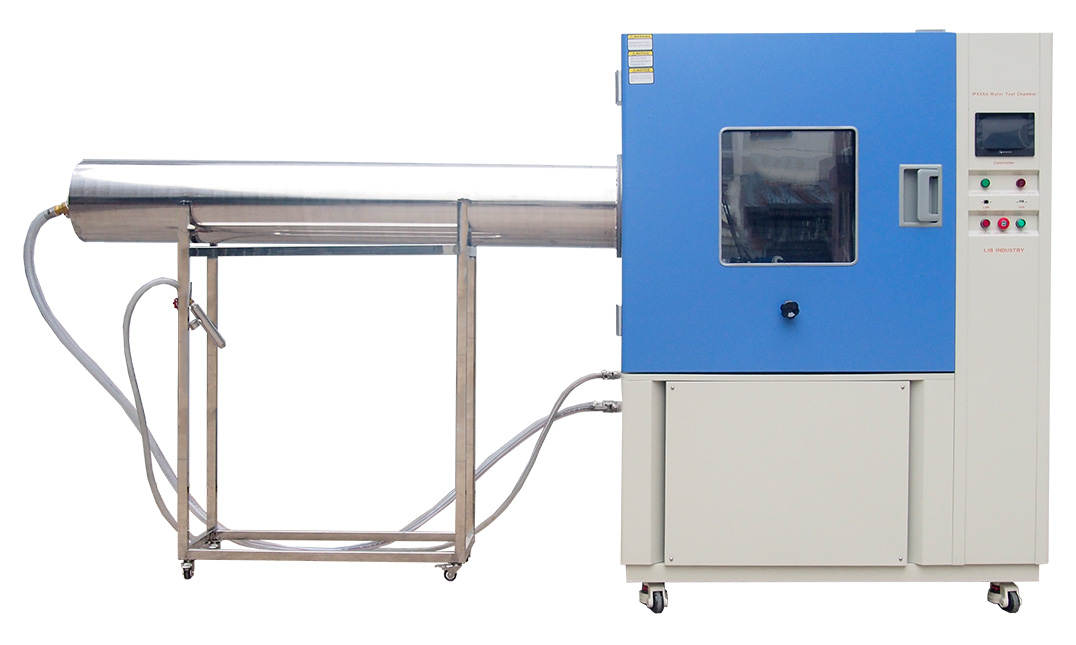

d. Chamber structure:

1. Inner chamber material: stainless steel plate SUS304;

2. outer chamber material: cold rolled steel A3+ paint/spray;

3. Observation window: one glass observation window;

4. lighting: a set of internal lighting, easy to observe the test.

1. Electronic and electrical industry

In the electronic and electrical industry, many products such as mobile phones, tablets, cameras, etc., need to have a certain waterproof performance. By using the IPX56 test chamber, we can ensure that these products will work properly in wet environments. For example, a mobile phone brand in the product development process, the use of IPX56 test chamber to carry out a strict waterproof performance test on the mobile phone, through continuous improvement of product design and process, and finally launched a mobile phone with excellent waterproof performance, which has been widely praised by consumers.

2. Auto parts industry

In the process of driving, the car may encounter various bad weather conditions, such as heavy rain, floods and so on. Therefore, auto parts such as lights, sensors, engines, etc., need to have good waterproof performance. By using the IPX56 test chamber for testing, you can ensure that automotive parts can still work properly in harsh environments. For example, in the production process of an auto parts supplier, IPX56 test chamber was used to test the headlights, and by improving the sealing structure and materials, the waterproof performance of the headlights was improved, thus reducing the after-sales maintenance rate of the products.

3. Communication equipment industry

Communication equipment such as base stations and antennas are usually installed outdoors and need to withstand the test of various natural environments. Therefore, communication equipment also needs to have good waterproof performance. By using the IPX56 test chamber for testing, it is possible to ensure that communication equipment can still work properly in harsh environments. For example, a communication equipment manufacturer used IPX56 test chamber to test the base station in the product development process, and improved the waterproof performance of the base station by optimizing the structural design and waterproof treatment process, thus improving the reliability and stability of the product.

In summary, the IPX56 test chamber, as a key equipment to ensure product quality, plays an important role in electronic and electrical appliances, auto parts, communication equipment and other industries. Through strict waterproof performance testing of products, we can ensure that products meet the standard requirements, find product design defects in advance, and reduce product after-sales maintenance costs.