Features and Benefits of PV Test Chamber

1. Accelerated aging testing of multiple PV modules at the same time can meet the quality inspection needs of mass production. It can not only improve the test efficiency, reduce the test cost, but also ensure the consistency of product quality.

2. Perfect safety protection system, if the photovoltaic module occurs short circuit, overheating and other abnormal conditions, the test room safety protection system will alarm in time and take appropriate protective measures.

3. Customized PV test schemes are supported according to different test requirements and standards. Whether it is a performance test for a specific type of photovoltaic module, or a certification test in accordance with international, national or industry standards.

4. Support a variety of test modes, such as static testing, dynamic testing, cyclic testing and so on. Different test modes can simulate the performance of photovoltaic modules in different working states.

Specifications of PV Test Chamber

Model | PV-04 |

Internal Dimension (mm) | 1300*700*1350 |

Overall Dimension (mm) | 1900*1100*1750 |

Interior Volume | 1220L |

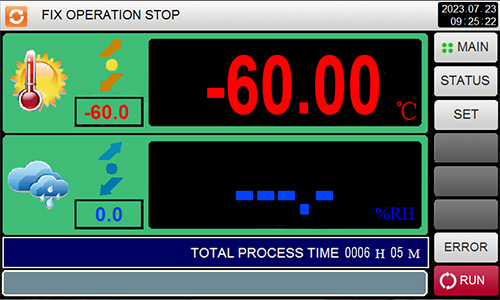

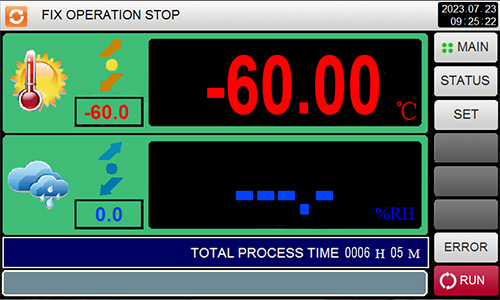

Parameter | Temperature Range | -60℃ ~ +100 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Temperature Change Rate | 1 ~ 3.4℃ / Min |

Panel Size | 1M*2M |

Panel Capacity | 4 / 6 / 8 / 10 / 12 Pieces |

Controller | Programmable color LCD touch screen controller |

Ethernet connection, PC Link, USB |

Humidity | Water supply system | Automatic water supply |

Water supply system | Water purification system |

Humidifier | External isolation, stainless steel surface evaporation humidifier |

Dehumidification | Evaporator |

Sensor | Temperature Sensor | PTR Platinum Resistance PT100Ω/MV A-class, accuracy 0.001℃ |

Humidity Sensor | Dry and wet bulb sensor |

Build-in Water Tank(mm) | 270*300*450 |

View Window Size(mm) | 330*370 |

Air Circulation | Centrifugal wind fan |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Refrigerant High-pressure Protection; Water Shortage Protection; Earth leakage Protection |

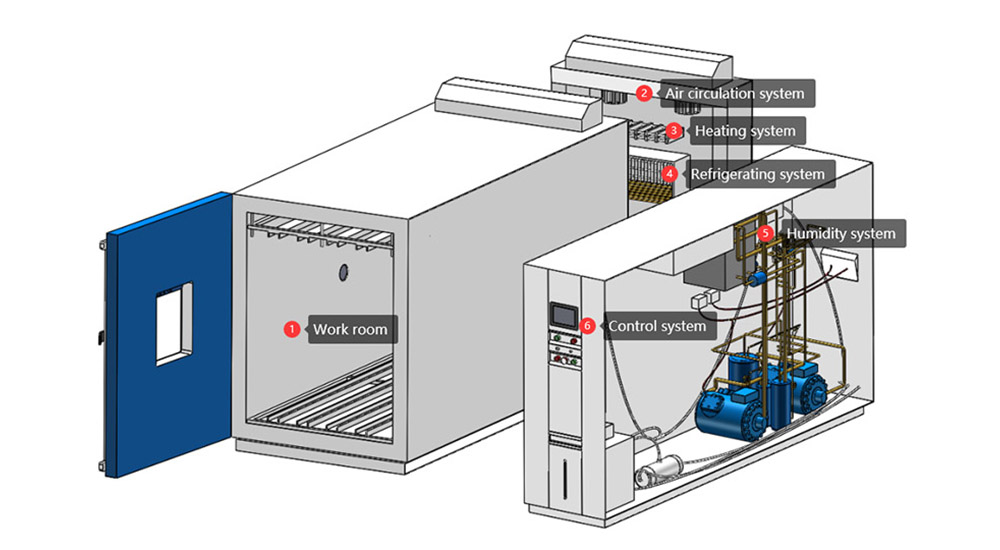

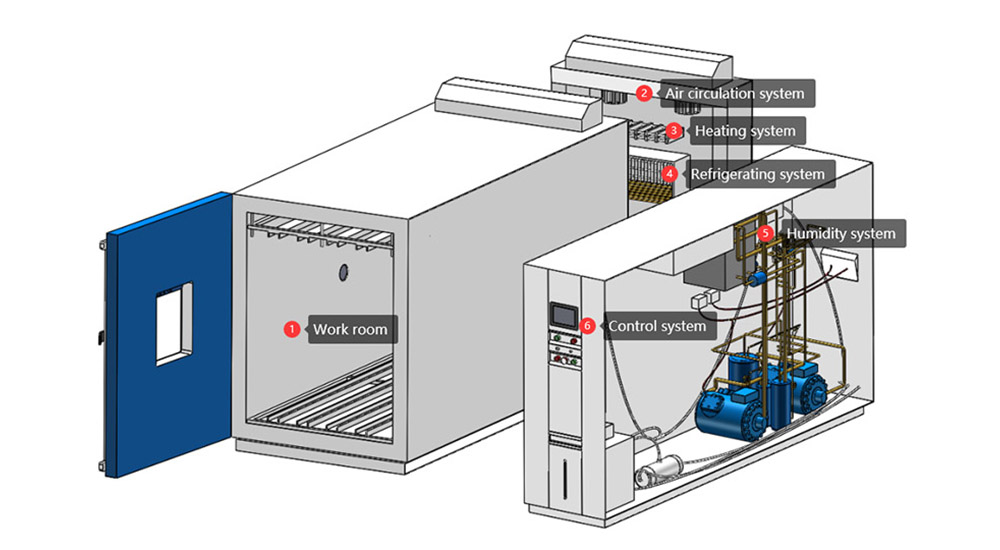

Configuration of PV Test Chamber

| 1. Workroom | The sample holder has good strength and corrosion resistance, can withstand the weight of the photovoltaic module, and can be adjusted in height. The sample holder will be equipped with a fixed device, and the photovoltaic module test angle can be adjusted.

|  |

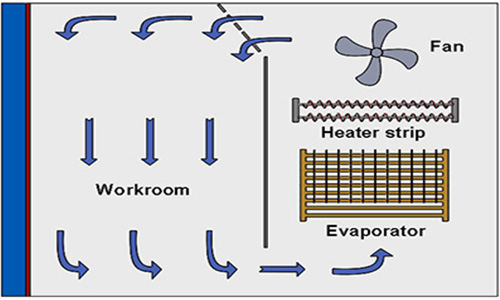

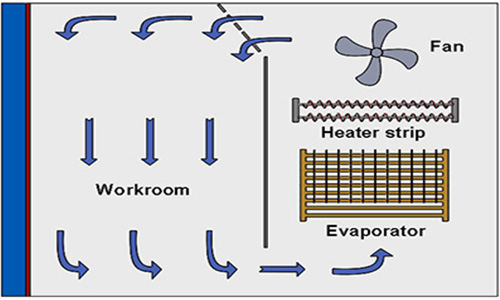

| 2. Air circulation system | Including fans and ventilation ducts, high-power fans are responsible for circulating air in the test room to keep temperature and humidity even. |  |

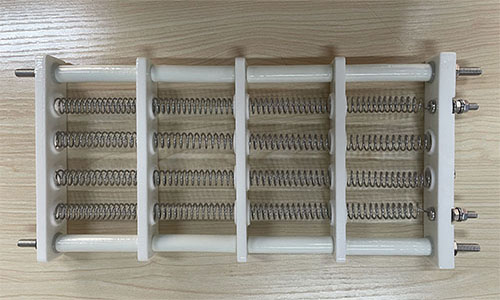

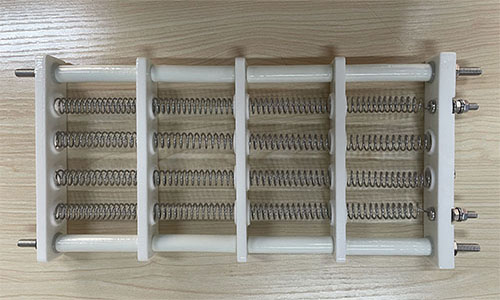

| 3. Heating system | High-power heating wires convert electrical energy into thermal energy, providing heat for the test chamber. |  |

| 4. Refrigerating system | The use of mechanical refrigeration, compressor refrigeration system core components, also including condenser, evaporator, refrigerant pipeline, etc. |  |

| 5. Humidity system | The evaporative humidifier can convert water into water vapor and increase the humidity inside the test chamber. |  |

| 6. Control system | The use of PLC programmable controller can automatically control the refrigeration system, heating system, ventilation system, etc., to achieve accurate control of the test room environment. The operation of man-machine interface is simple and intuitive. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español