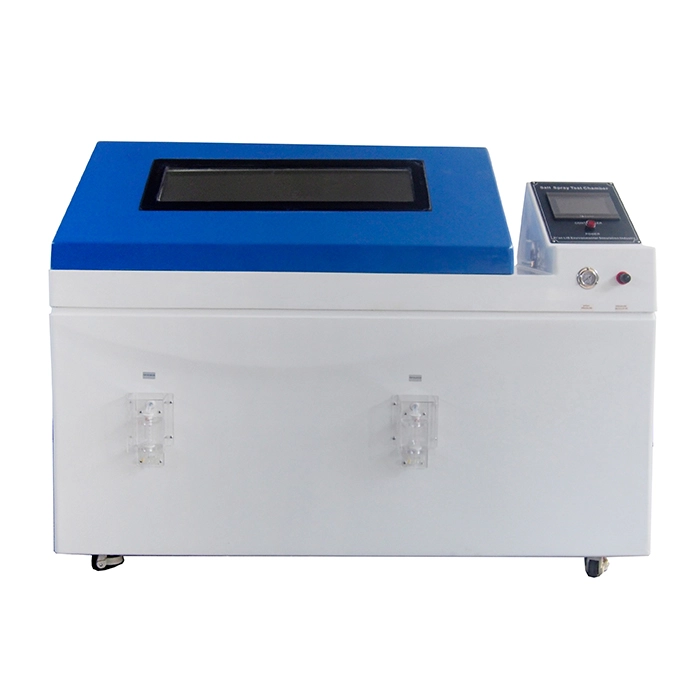

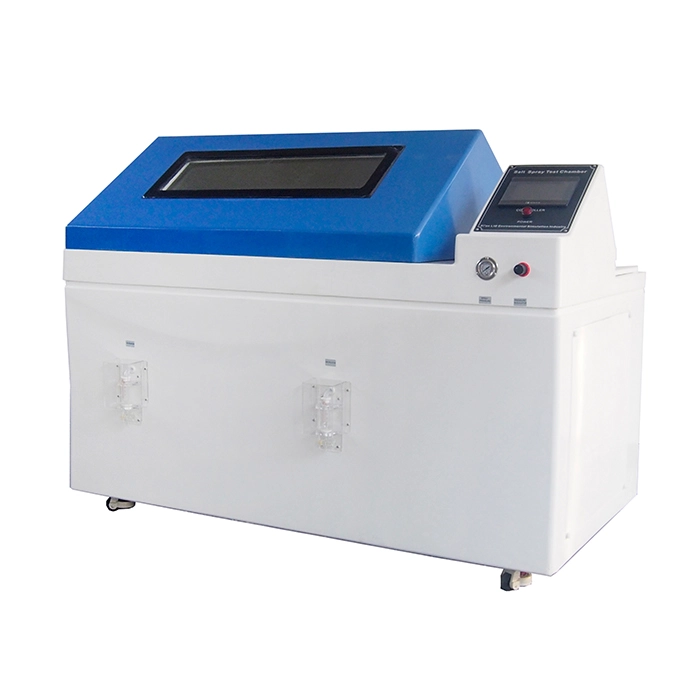

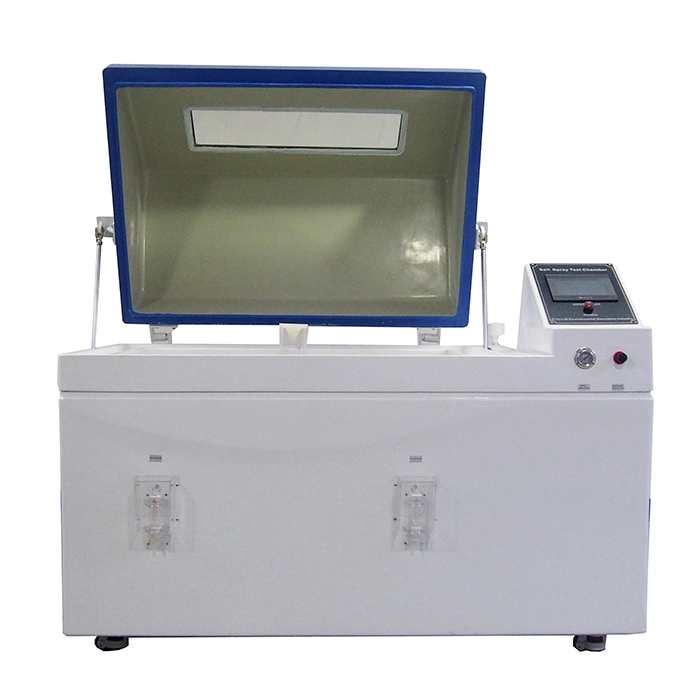

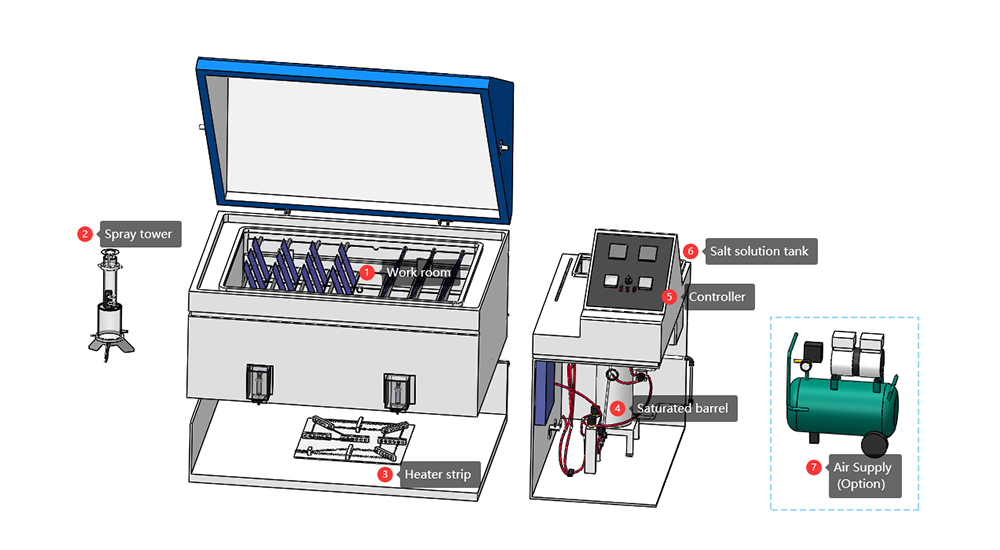

Salt spray corrosion test chamber reproduce coastal and marine climate. After the NACL solution is atomized, a salt spray environment is formed to surround the sample with controlled temperature to detect the salt spray corrosion resistance of the material or product.

Able to perform basic and continuous salt spray tests, complying with ASTM B117, ISO 9227.A large selection accommodates various types of product testing.

Model: S-150,S-250, S-750, S-010, S-016, S-020

Standard: ASTM B117, ISO 9227, ASTM G85, D17 2028, SAE J2334, ISO4611, ISO7253, IEC 60068-2-11, ASTM G85-02e1 Annex A1, DIN 50021, ASTM B368

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español