Features and Benefits of Benchtop Temperature Chamber

1. The compact shape design of the benchtop temperature chamber, small footprint, very suitable for small test pieces, can be easily placed on the bench, convenient for space limited environment.

2. The temperature sensor monitors the temperature in the chamber, and the double-layer high and low temperature resistant seal and 10cm insulation layer prevent temperature leakage. The air duct design further improves the uniformity of temperature, so that the temperature deviation is controlled at ± 2℃.

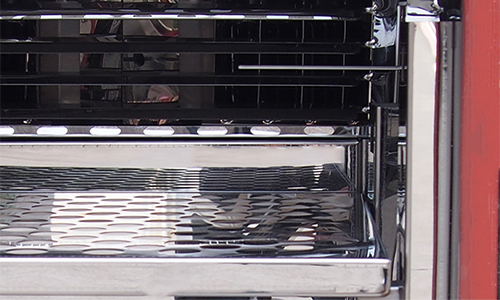

3. Convenient observation and testing: with a large observation window and attached with lighting fixtures.The left side of the benchtop temperature chamber is equipped with a cable hole for powering up the test piece.

4. LIB Industry Benchtop temperature chamber has less power and lower energy consumption, and can save energy costs in the long-term use process. And this benchtop temperature chamber is a cost-effective choice too.

Specifications of Benchtop Temperature Chamber

Model | TH-50 | TH-80 |

Internal Dimension (mm) | 320*350*450 | 400*400*500 |

Overall Dimension (mm) | 820*1160*950 | 900*1210*1000 |

Interior Volume | 50L | 80L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

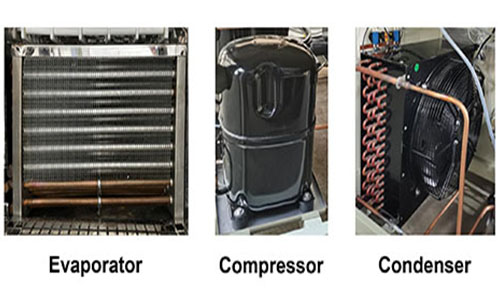

Cooling system | Mechanical compression refrigeration system |

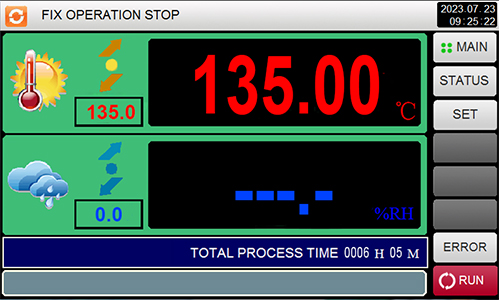

Controller | Programmable color LCD touch screen controller Ethernet connection |

Safety Device | Humidifier Dry-combustion protection; Over-temperature Protection; Over-current Protection; Refrigerant High-pressure protection; Water Shortage Protection; Earth leakage Protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Thermal Insulation | Polyurethane foam and insulation cotton |

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing |

Standard Configuration | 1 Cable hole (Φ 50,) with plug; 2 shelves |

Weight | 190kgs | 220kgs |

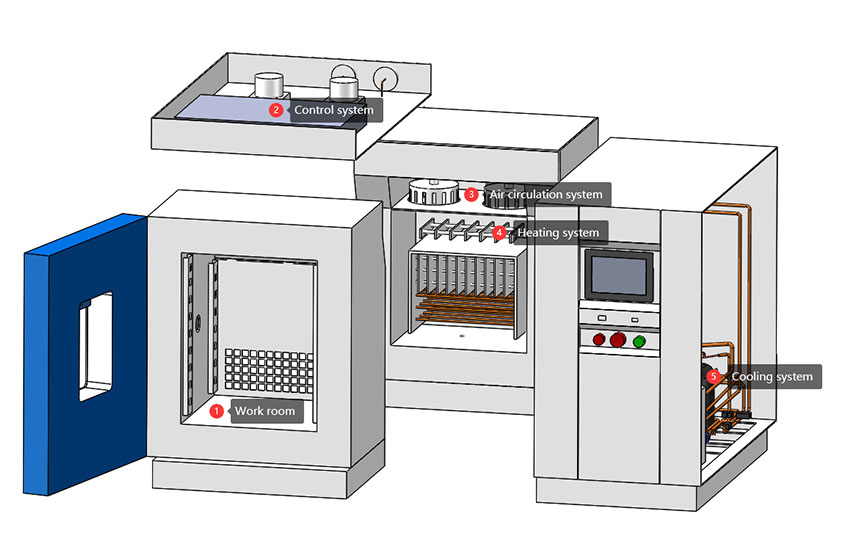

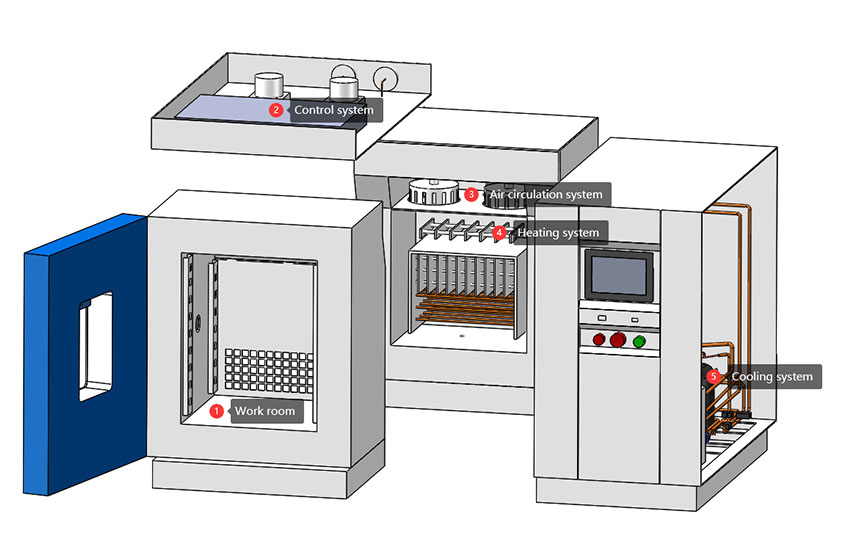

Configuration of Benchtop Temperature Chamber

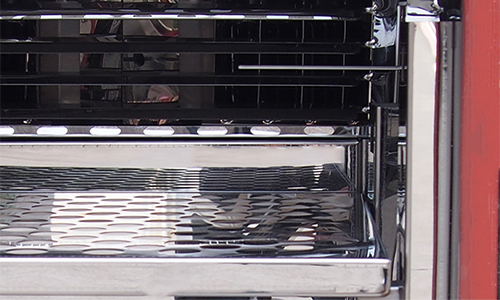

① Workroom | The internal material is SUS 304 stainless steel, mirror surface, rust-proof to high and low temperature and moisture corrosion Punching sample shelf 2pcs andthe height is adjustable Equipped with PT-100 Class A sensor, accuracy at 0.001 degrees. |

|

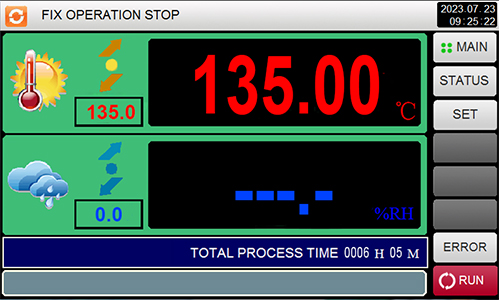

② Control system | Precisely set the temperature range, for example, can be accurately adjusted between -20 ° C,-40 ° C and -70 ° C to 150 ° C, the error can be controlled within ±0.5 ° C. Test parameters such as temperature and time can be easily set through the operation interface. |  |

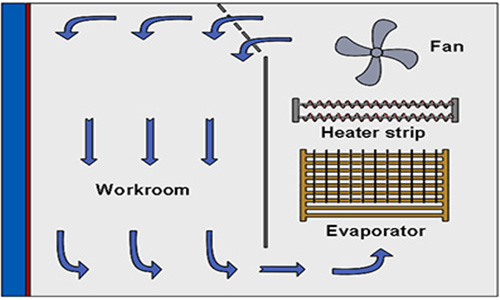

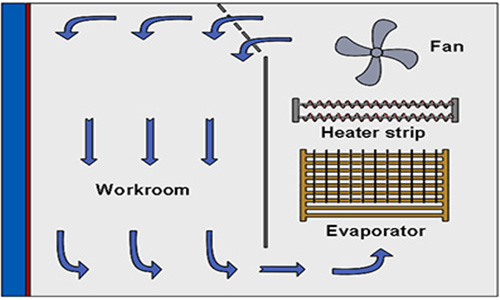

③ Air circulation system | The air circulation system is driven by a strong fan to ensure the uniform flow of air in the benchtop temperature chamber, so that the temperature uniformity is controlled within ±2℃. |  |

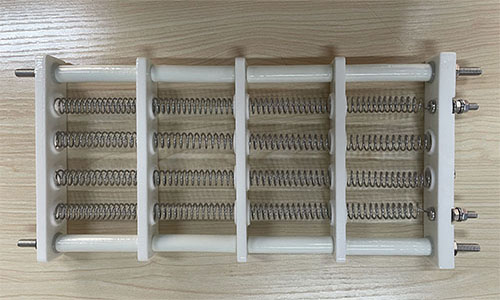

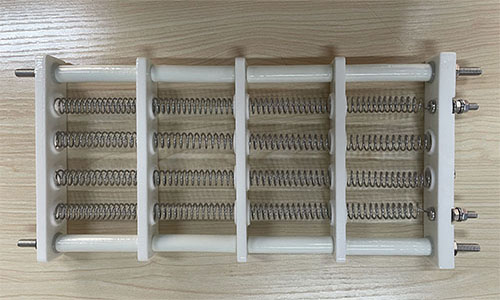

④ Heating system | The electric heating wire increases the temperature in the benchtop temperature chamber.The heating rate can reach 3℃ per minute. |  |

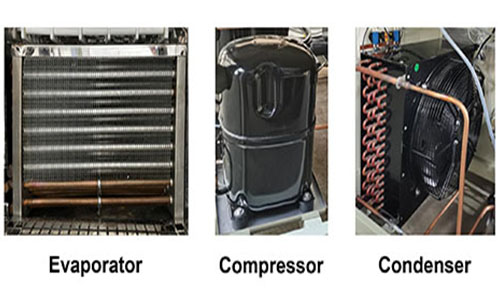

⑤Cooling system | Using compressor refrigeration, cooling rate can reach 1℃ per minute. The cooling system is also equipped with efficient condensers and evaporators to ensure efficient and stable cooling. |  |

The benchtop temperature chamber is small in size, easy to operate, with accurate temperature control system, efficient air circulation system, reliable heating and cooling system, suitable for a variety of products and materials temperature test. Sufficient inventory, 1-3 days can be shipped. Contact us below to send you more details and a quote.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español