Features and Benefits of IP5X Test Chamber

Precise control of dust concentration, distribution uniformity, the talcum powder amount is controlled at 2kg~4kg/m³.

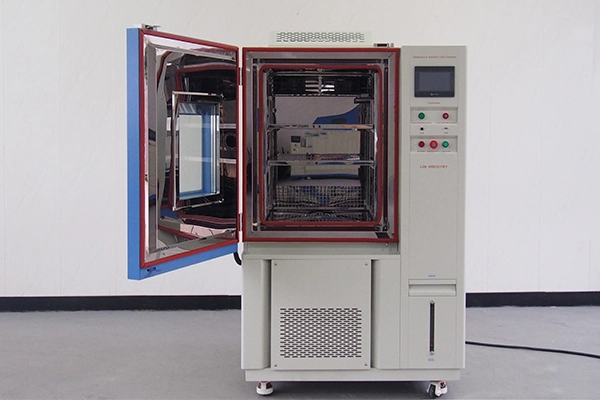

Observation window with wiper is convenient for users to observe the status of the sample in real time during the test process.Gloves can also be installed on the door to facilitate the turning of the test parts during the test.

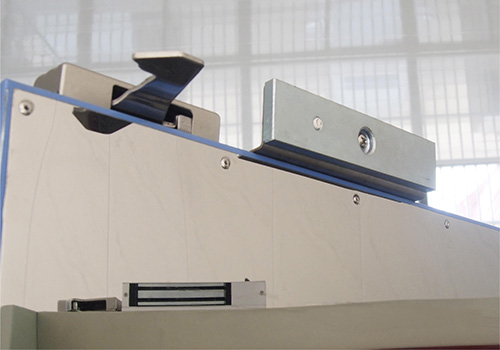

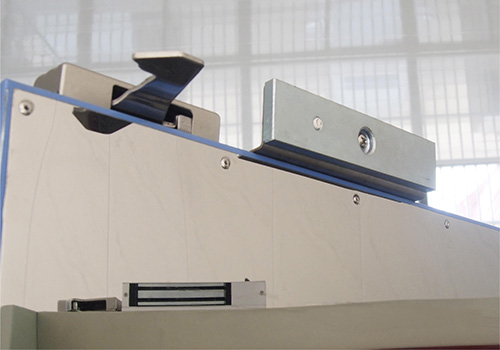

The electromagnetic lock generates a strong suction force and tightly attract the iron plate to lock the door. For safety and prevent malfunction, avoiding pollution to the surrounding environment.

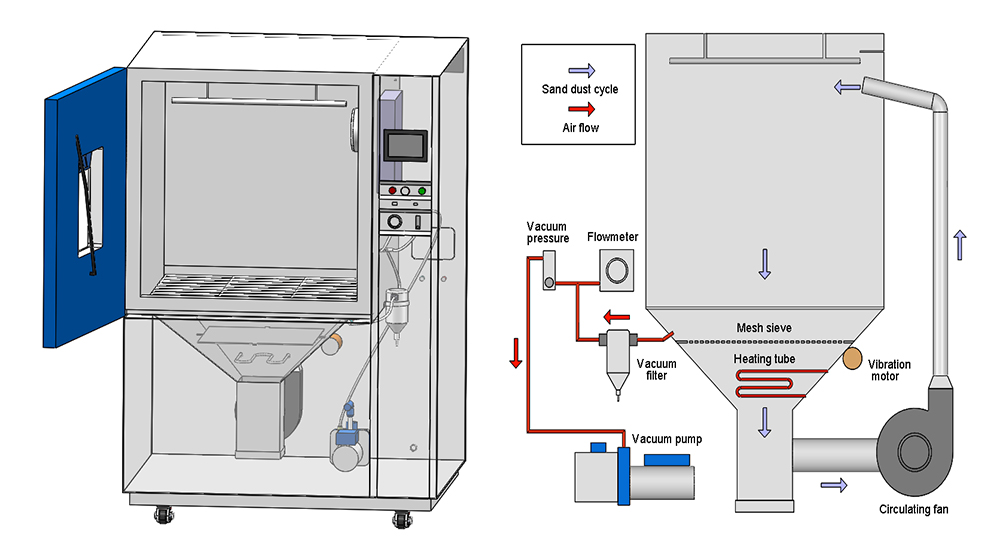

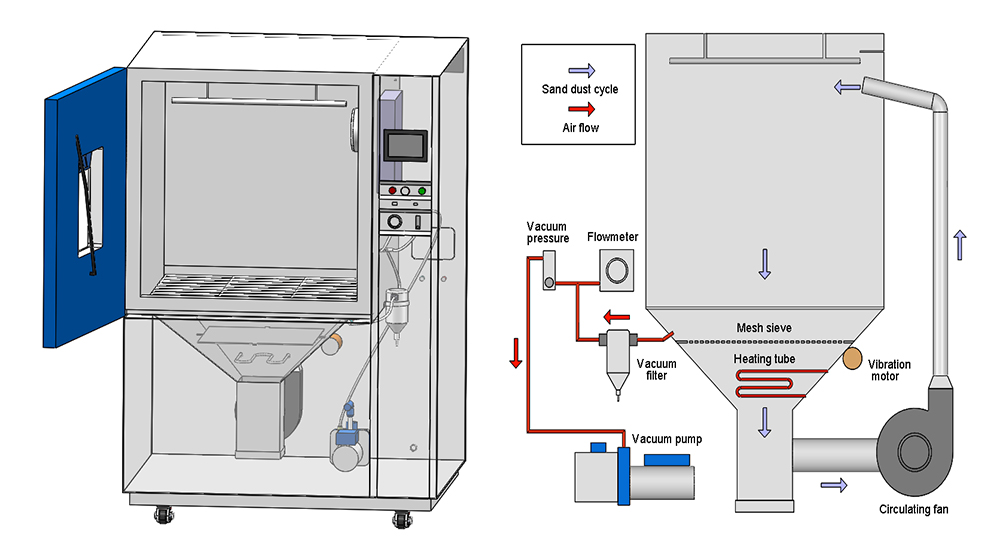

Heater avoids the dust moisture condensation, to ensure that the dust in a dry, loose state, mesh screen can screen the nominal distance ≤75um, nominal line diameter 50µm dry talc powder and other specific particle size dust, to ensure the simulation of dust environment.

Specifications of IP5X Test Chamber

Model | DI-800 | DI-1000 | DI-1500 | DI-2000 |

Internal Dimension (mm) | 800*1000*1000 | 1000*1000*1000 | 1000*1500*1000 | 1000*2000*1000 |

Overall Dimension (mm) | 1040*1450*1960 | 1330*1450*1960 | 1330*1950*1990 | 1330*2450*1990 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ |

Humidity Range | < 30% RH |

Normal Wire Diameter | 50um |

Nominal Width of a Gap Between wires | 75um |

Fight Time | 0 ~ 99H59M |

Blowing Time | 0 ~ 99H59M |

Specimen Power Outlet | Dust-proof socket 16A |

Configuration of IP56 Waterproof Chamber

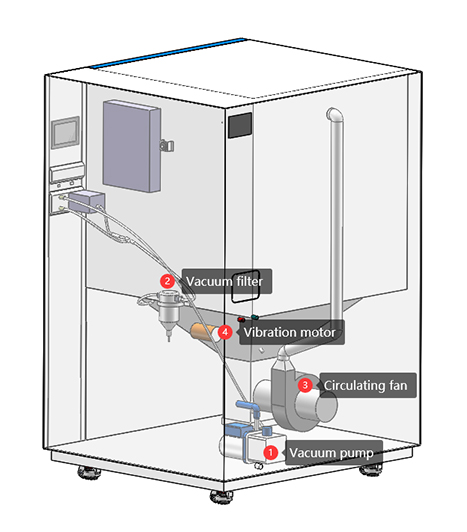

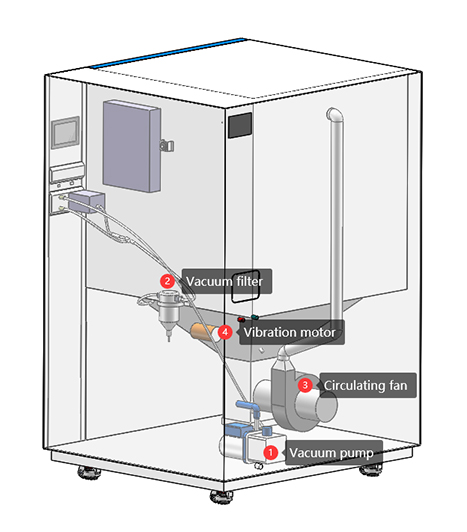

①Vacuum pump

According to IP5X test standards, it is necessary to use a vacuum pump to keep the air pressure inside the tested shell below atmospheric pressure to create negative pressure environment, so as to simulate the air pressure difference that may be encountered in actual use of the product and test the dustproof performance.

②Vacuum filter

The vacuum filter can filter out dust particles and other impurities in the air, prevent these impurities from entering the vacuum pump, avoid damage to the vacuum pump, and extend the service life.

③Circulating fan

Uniform dust dispersion: Ensure that the surface of the tested sample can be uniformly exposed to dust, simulate the real situation of the product in the actual dust environment, and maintain the dust suspension state.

④Vibrating motor

Avoid the accumulation of dust on the surface of the sample, ensure that the dust can fully contact the various parts of the sample, and shake off the dust stuck to the inner wall of the workroom

Vertical circulation air blows dust to the workroom, forming a dust circulation system,and dust can be recycled use.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español