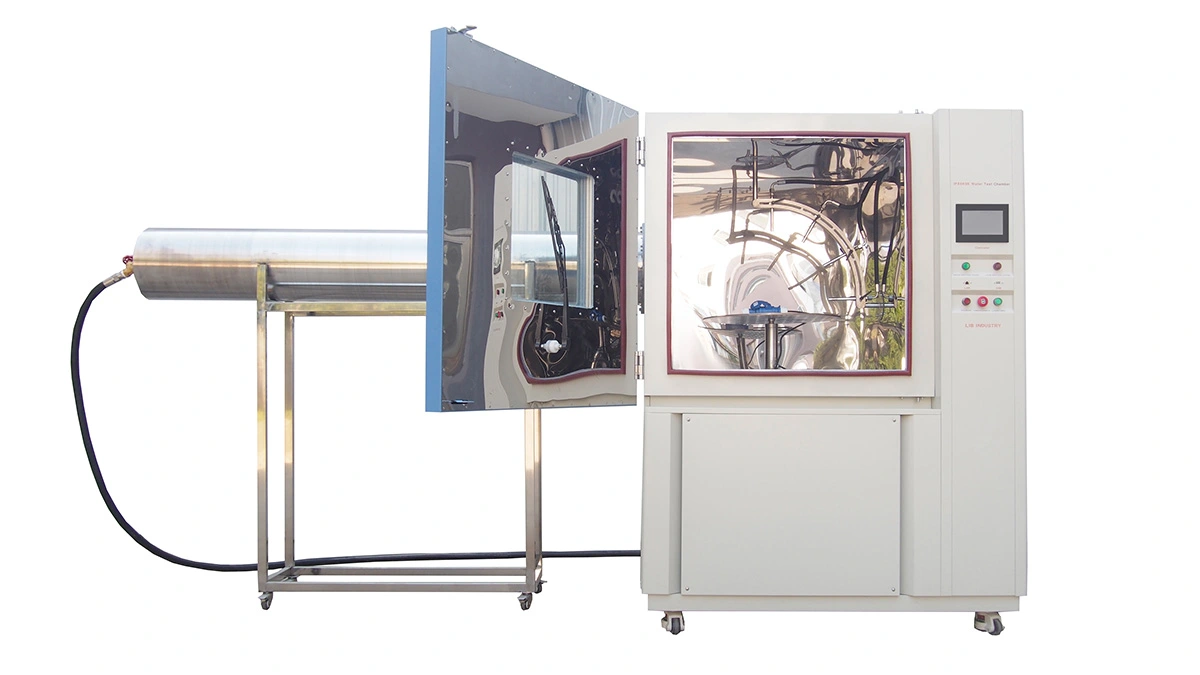

Industrial vacuum ovens operate by drying materials under negative pressure within a industrial vacuum ovens. Utilizing a vacuum pump to remove air and moisture, the chamber achieves a vacuum state, accelerating the drying process.

Industrial vacuum ovens are extensively used in fields such as biochemistry, pharmaceutical chemistry, medical and health sectors, agricultural research, and environmental protection. They are designed for efficient and rapid drying of powders, and drying of easily decomposable, easily oxidized substances, and complex components.

The ovens comply with testing standards such as UN 38.3, UL 1642, and IEC61960.

Model Specifications: VO-20/30/50/90

Internal Dimensions (WHD): 300X300X275, 320X320X300, 415x370x345, 450x450x450(mm)

External Dimensions (WHD): 610x490x450,630x510x490,730x560x550, 740x610x595 (mm)

Power Supply: Single-phase three-wire 220V 50Hz or three-phase five-wire 380V 50Hz

Temperature Range: RT (room temperature) +35 to +150℃

Internal Material: Stainless steel

External Material: A3 steel plate with high-grade paint treatment (thickness 3.0mm)

Timer: Three-digit display 999 (H hours, M minutes, S seconds switchable)

Vacuum Degree: -133Kpa (digital display, adjustable)

Vacuum Pump: Standard configuration

Heating Material: High-temperature resistant heating tubes.

Temperature Setting Range: RT +35℃ to 150℃, freely set to the desired temperature.

Programmable Temperature Controller: Adjust heating time to reach the required temperature.

The PID controller automatic temperature control system uses a sensitive detection sensor to sense the chamber temperature, feeding it back to the PID controller. The PID controller quickly adjusts the output power to maintain the precise set temperature.

Overtemperature Protection: The entire unit is equipped with an overtemperature protection system and an automatic fuse system to handle excessive power.

High-Temperature Protection: If external forces cause temperature to run out of control, this system will automatically stop power supply when the temperature exceeds the set point by 10 degrees, protecting both the product and the machine.

Overcurrent Protection: If external voltage is too high or other reasons cause the unit's power to exceed normal levels, this system will automatically cut off the power to protect the machine's control components from damage.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español