Features and Benefits of Constant Temperature and Humidity Test Chamber

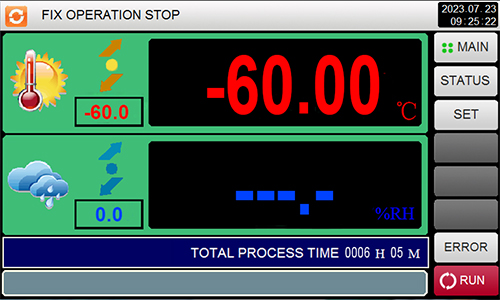

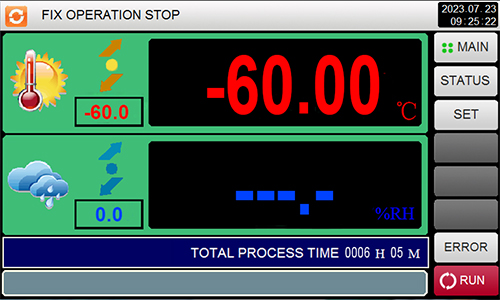

1. Advanced control system and high-precision sensor, temperature control accuracy up to ±0.1℃, humidity control accuracy up to ±2%RH, can accurately simulate a variety of temperature and humidity environment.

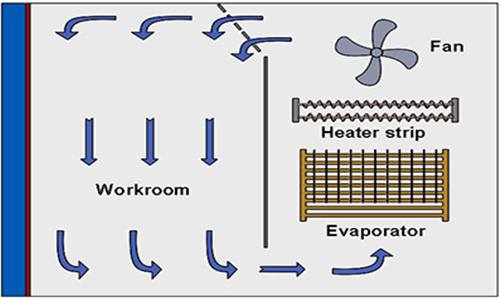

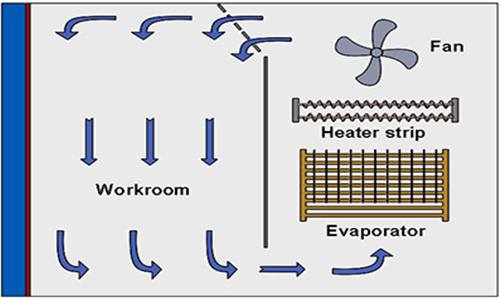

2. The rotating fan installed on the top of the chamber can realize air circulation, balance the temperature and humidity in the chamber, and make the temperature and humidity uniformity in the chamber reach a high standard.

3. The use of advanced energy-saving technology, such as insulation materials, reduce energy consumption, save operating costs, in line with environmental protection and energy saving requirements.

4. Suitable for product testing in many industries such as electronics, electrical appliances, communications, automobiles, plastics, rubber, chemical, biomedical, agricultural research, etc., and can meet different testing needs.

Specifications of Constant Temperature and Humidity Test Chamber

Model | TH-100 | TH-500 | TH-800 | TH-1000 |

Internal Dimension (mm) | 400*500*500 | 700*800*900 | 800*1000*1000 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1200*1340*2020 | 1300*1540*2120 | 1500*1540*2140 |

Interior Volume | 100L | 500L | 800L | 1000L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

Cooling system | Mechanical compression refrigeration system |

Refrigerating unit | French TECUMSEH compressor |

Heating Element | Nichrome heater |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water supply system | Automatic water supply, Water purification system |

Humidifier | External isolation, stainless steel surface evaporation humidifier |

Safety Device | Humidifier dry-combustion protection; over-temperature protection; over-current protection; Refrigerant high-pressure protection; Water shortage protection; Earth leakage protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Thermal Insulation | Polyurethane foam and insulation cotton |

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing |

Standard Configuration | 1 Cable hole with plug; 2 shelves |

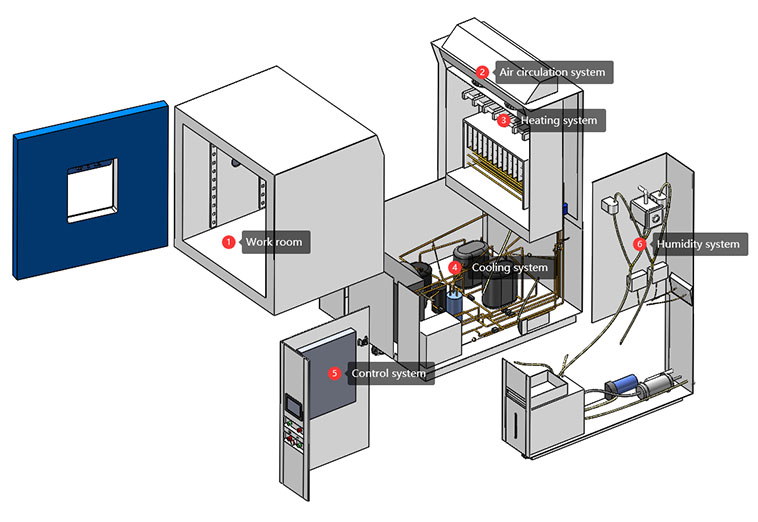

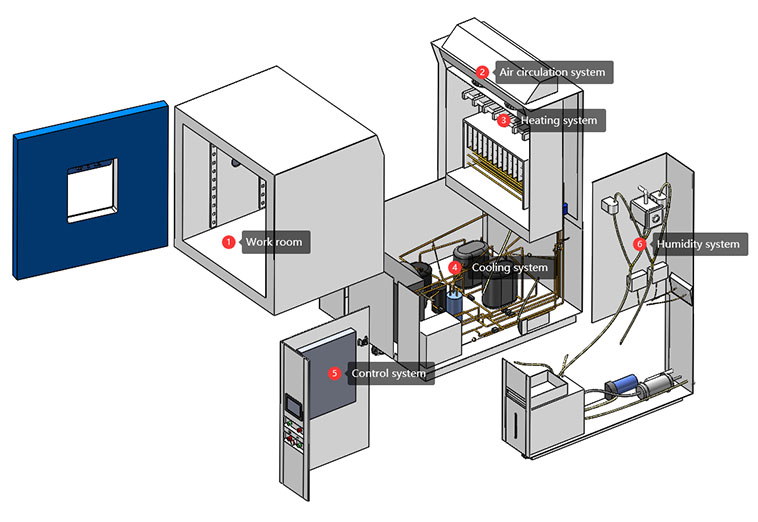

Configuration of Constant Temperature and Humidity Test Chamber

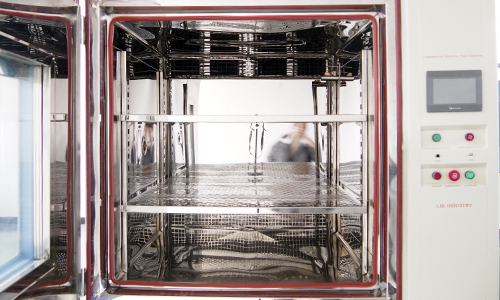

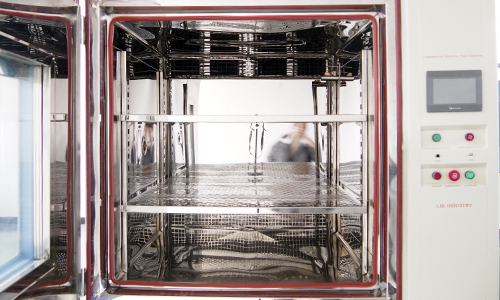

① Workroom | SUS304 stainless steel with good corrosion resistance and thermal conductivity. Equipped with double punch design sample holder, adjustable height, bearing 50KG each layer.

|  |

② Air circulation system

| The circulating fan is installed on the top of the workroom, and the motor drives the fan to rotate, so that the air in the chamber forms a circulation flow to ensure the uniformity of temperature and humidity. |  |

③ Heating system | |  |

④ Cooling system | Composed of compressor,condenser, evaporator, throttling device. Compressor is the core of the refrigeration system, by compressing the refrigerant gas, so that its pressure and temperature rise.

|  |

⑤ Humidity system | Water is turned into steam by electric heating, and then steam is injected into the chamber to increase humidity, which can meet the simulation demand of high humidity environment. |  |

⑥ Control system | Regulate heating, cooling and humidity systems. Meantime, the controller can also realize the programming control of the test process, such as setting the temperature and humidity curve, the number of cycles, etc. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español