PV Module Test Chamber Features and Benefits

1. Accelerate the aging process of photovoltaic modules by simulating extreme environmental conditions and evaluate their long-term performance and reliability in a shorter period of time.

2. According to the size and design of the test chamber, multiple photovoltaic modules can be tested at the same time, improving the test efficiency and meeting the test needs in large-scale production and research and development.

3. The test chamber is designed and manufactured in accordance with relevant international standards and industry specifications, such as IEC 61215, IEC 61646, etc.

4. Stable test environment and precise control parameters ensure repeatability and comparability of test results. For the same photovoltaic module, multiple tests are conducted under the same test conditions, and the deviation of the results is small.

Specifications of PV Module Test Chamber

Model | PV-04 |

Internal Dimension (mm) | 1300*700*1350 |

Overall Dimension (mm) | 1900*1100*1750 |

Interior Volume | 1220L |

Parameter | Temperature Range | -60℃ ~ +100 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Temperature Change Rate | 1 ~ 3.4℃ / Min |

Panel Size | 1M*2M |

Panel Capacity | 4 / 6 / 8 / 10 / 12 Pieces |

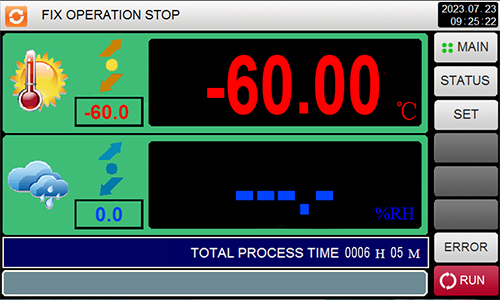

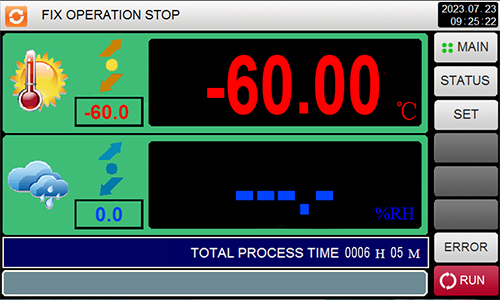

Controller | Programmable color LCD touch screen controller |

Ethernet connection, PC Link, USB |

Humidity | Water supply system | Automatic water supply |

Water supply system | Water purification system |

Humidifier | External isolation, stainless steel surface evaporation humidifier |

Dehumidification | Evaporator |

Sensor | Temperature Sensor | PTR Platinum Resistance PT100Ω/MV A-class, accuracy 0.001℃ |

Humidity Sensor | Dry and wet bulb sensor |

Build-in Water Tank(mm) | 270*300*450 |

View Window Size(mm) | 330*370 |

Air Circulation | Centrifugal wind fan |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Refrigerant High-pressure Protection; Water Shortage Protection; Earth leakage Protection |

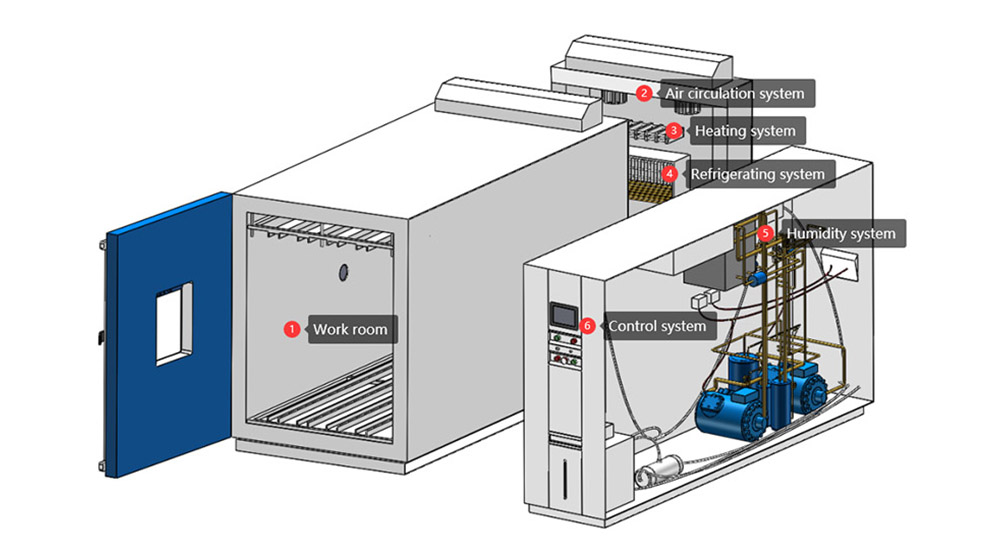

Configuration of PV Module Test Chamber

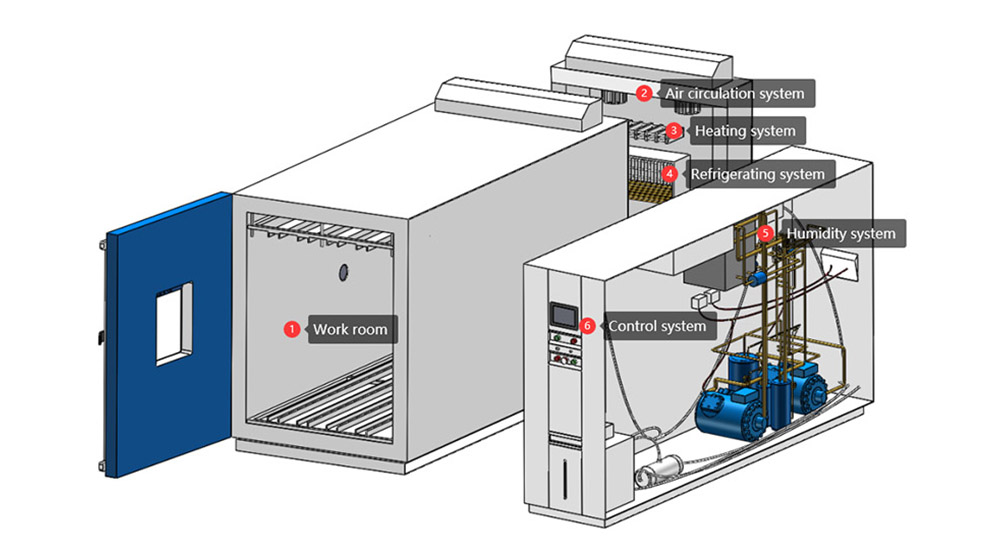

①Workroom |

The workroom uses SUS304 with corrosion resistance and high temperature resistance. A double heat-stable silicone rubber seal is installed between the door and the housing. Equipped with temperature and humidity sensor. The sample holder can be adjusted, such as adjusting the distance and angle of the sample holder, to meet the test needs of different specifications of PV modules.

|  |

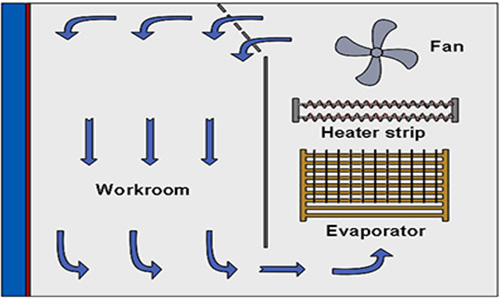

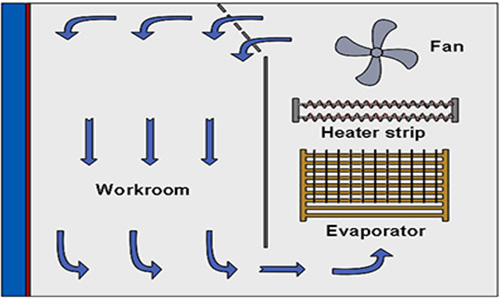

②Air circulation system | Install multiple axial fans. Promote the circulation of air so that temperature, humidity and other customized environmental factors are evenly distributed in the test space to avoid local environmental differences. |

|

③Heating system | The resistance wire heating can quickly and evenly heat the air inside the test chamber to achieve a rise in temperature with 1-3.4℃/min. |  |

④Refrigerating system | The refrigeration system adopts mechanical compression refrigeration, which is composed of compressor, condenser, evaporator, throttle valve and other components.

|  |

⑤Humidity system | A steam humidifier that converts water to water vapor and increases the humidity inside the test chamber. | .jpg) |

⑥Control system | Programmable color LCD touch screen controller. The controller can accurately control it according to the set parameters to realize the automatic adjustment of the test environment. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español

.jpg)