In the field of materials science and product quality inspection, xenon weatherometer play a crucial role. It is able to simulate factors such as solar radiation, temperature, humidity in the natural environment, and perform accelerated aging tests on materials and products to evaluate their weather resistance and service life. This article will delve into the principle, structure, characteristics, wide application areas, standards and specifications and operating steps of the xenon weatherometer to help you fully understand this important test equipment.

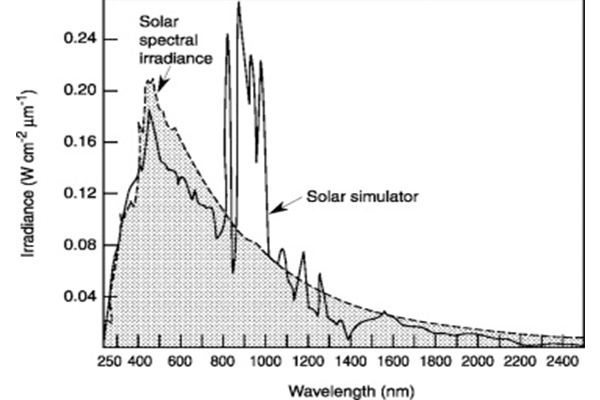

The core principle of xenon weatherometer is to use xenon lamp to simulate the full spectrum radiation of sunlight. Xenon lamps are capable of producing a spectral distribution similar to that of sunlight, including ultraviolet, visible and infrared regions. By controlling the parameters of irradiation intensity, temperature, humidity and spray rainfall, the natural climate conditions in different regions and different seasons can be simulated.

During testing, the material or product being tested is exposed to xenon lamp radiation, as well as changes in temperature and humidity and possible rainfall spraying. These factors work together to accelerate the aging process of the material so that it exhibits a similar change in properties to long-term natural aging in a relatively short period of time.

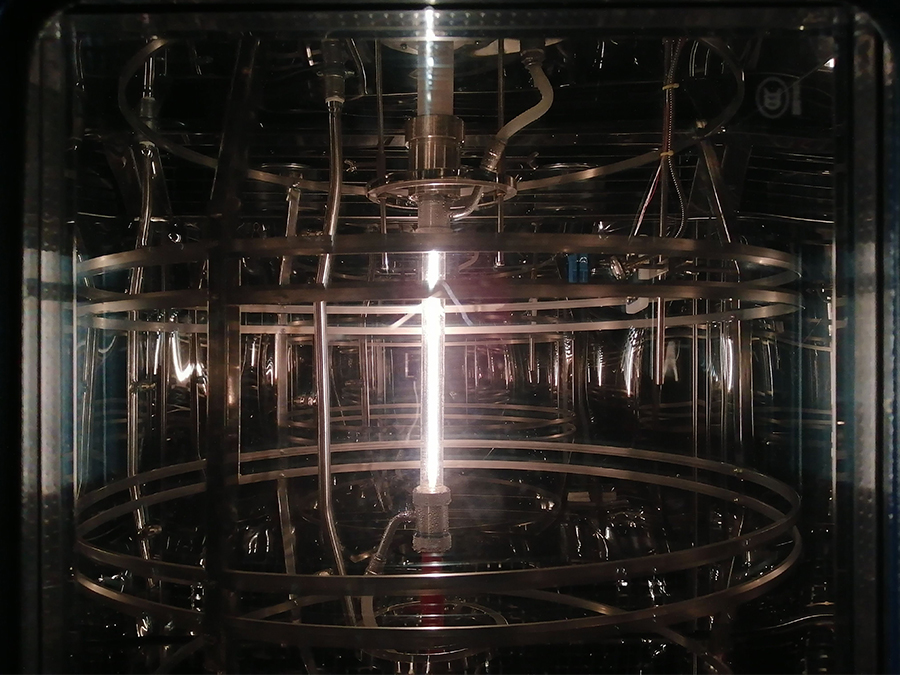

1. Light source

Xenon lamp is the key light source of xenon weatherometer, usually using long-arc xenon lamp or pulsed xenon lamp. Long-arc xenon lamps can provide stable continuous spectral radiation, while pulsed xenon lamps can produce higher intensity momentary radiation, which is suitable for some special test needs.

2. Filter system

In order to more accurately simulate different natural spectral conditions, xenon weatherometers are usually equipped with light filtering systems. By using different types of filters, the wavelength distribution of the xenon lamp spectrum can be adjusted, for example to simulate sunlight passing through the atmosphere, conditions for UV enhancement, and so on.

3. Temperature control system

Temperature is one of the important factors affecting the aging of materials. xenon weatherometers are usually equipped with heating and cooling units that can precisely control the temperature in the test chamber within a certain range to simulate different climatic temperature conditions.

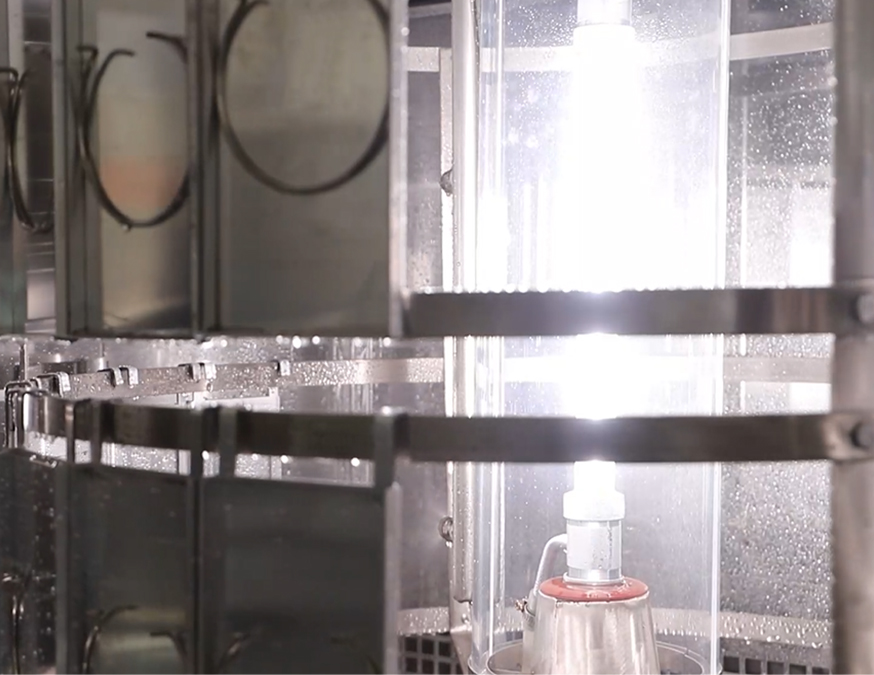

4. Humidity control system

Humidity also has a significant effect on the aging of materials. Through humidification and dehumidification devices, the test machine can adjust the humidity of the test environment and simulate the climate environment of high humidity or low humidity.

5. Water spray system

For some tests that require consideration of the effects of rainfall, the xenon weatherometer can be equipped with a rain spray to simulate the conditions of natural rainfall.

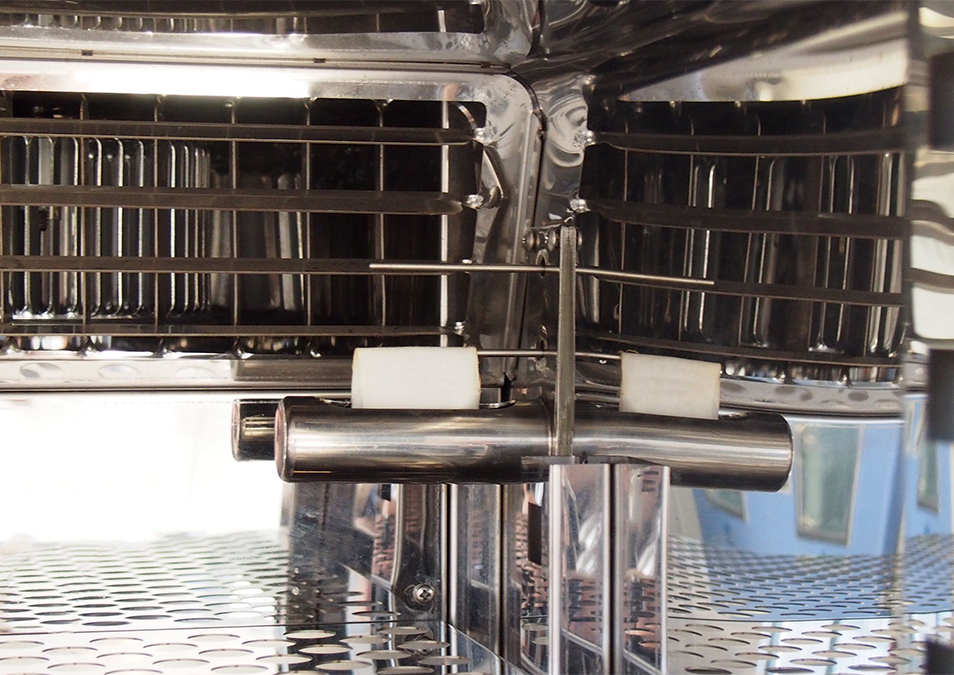

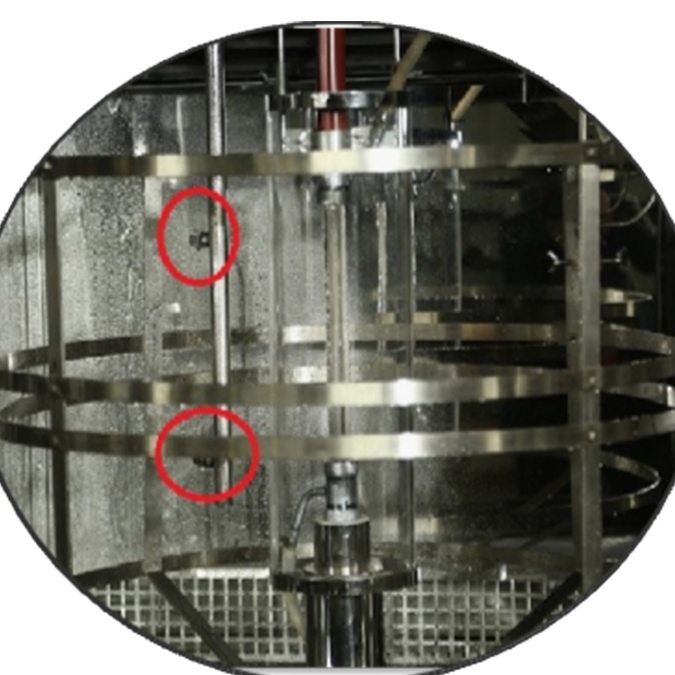

6. Sample placed system

In order to ensure that the sample is uniformly irradiated and affected by temperature and humidity, the test machine is usually equipped with a sample rotation device and a blast system to make the air flow inside the chamber uniform.

1. High simulation authenticity

Due to the ability to simulate the full spectrum of sunlight radiation and a variety of climatic factors, the xenon weatherometer provides a highly realistic aging environment, and the test results are closer to actual use.

2. Accelerated aging effect is significant

Through reasonable control of test parameters, the aging process of materials can be accelerated in a short time, which greatly shortens the test cycle and improves the test efficiency.

3. Good repeatability

As long as the test conditions are set the same, the xenon burn-in tester provides stable and repeatable test results, facilitating the comparison of results between different batches and different laboratories.

4. Versatility

It can flexibly adjust the test parameters according to different test standards and needs, and is suitable for aging testing of various materials and products.

1. Plastics and rubber industry

Plastic and rubber products are vulnerable to the effects of sunlight, temperature and humidity when used outdoors. The weathering resistance of plastic pipes, plastic films, rubber seals and other products can be evaluated through xenon aging test, which provides a basis for product development and quality control.

2. Coatings and paints industry

The durability of coatings and paints is directly related to the protective effect of surfaces such as buildings and vehicles. Xenon aging test can check the color change, gloss loss, powder and other aging phenomena of coatings and paints, and help enterprises optimize product formulations and improve product quality.

3. Textile industry

Textiles need to stand the test of sun exposure and climate change when used outdoors. Xenon aging test can evaluate the performance changes of textiles such as fading and strength decline, and provide support for the development of textile fabrics with good weather resistance.

4. The automotive industry

The exterior parts of the car, such as bumpers, body paint, interior materials, etc., need to have good weather resistance. Xenon burn-in testing can play an important role in the development and quality inspection of automotive components, ensuring the appearance and performance of the car in a variety of climatic conditions.

In order to ensure the accuracy and comparability of test results, a series of xenon aging test standards and specifications have been developed internationally. For example, ISO 4892 series standards specify xenon arc lamp aging test methods for plastic materials; The ASTM G155 standard provides detailed guidance for xenon lamp exposure testing of non-metallic materials. When conducting xenon aging tests, appropriate test conditions and evaluation indexes should be selected according to relevant standards and specifications.

1. Sample preparation

According to the requirements of the test standard, prepare the appropriate size and quantity of samples, and perform pretreatment on the samples, such as cleaning, drying, etc.

2. Test parameter Settings

According to the properties of the sample and the test purpose, xenon lamp irradiation intensity, temperature, humidity, rainfall period and other test parameters are set.

3. Sample installation

The sample is mounted on the sample rack in the test chamber to ensure that the sample is evenly exposed to radiation and environmental effects.

4. Test start

Start the xenon burn-in test machine and begin the test process. During the test, the test parameters and the status of the sample are regularly monitored.

5. Test end and sample evaluation

The test is terminated when the predetermined test time is reached or the specified aging of the sample occurs. The appearance, performance and other aspects of the tested samples were evaluated, such as color change, mechanical property decline, surface roughness, etc., and compared with the untested samples.