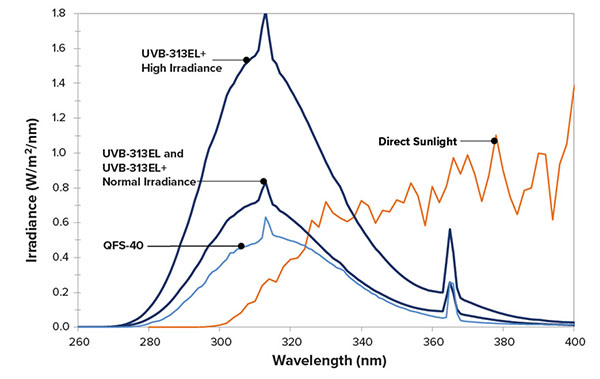

For material weather resistance testing, UV aging test chamber is the core equipment to simulate the aging behavior of materials under natural light conditions. Among them, UVA340 lamp and UVB313 lamp, as two mainstream UV light sources, are suitable for different test scenarios due to their different spectral characteristics.

The emission spectrum of the UVA340 lamp is concentrated near 340nm, which is highly consistent with the ultraviolet band of 295-365nm in sunlight, and can accurately reproduce the ground ultraviolet characteristics filtered by the atmosphere. ASTM G154 standard has shown that the spectral distribution of UVA340 is more than 90% similar to the ultraviolet portion of midday summer sunlight, making it the preferred light source for outdoor material aging tests.

Differently the UVB313 lamp is concentrated in the 313nm short-wave UV region, and its energy intensity is about 40% higher than that of the UVA340. This high-energy short wave can significantly accelerate the photodegradation rate of the material.

Test Requirements | UVA340 application | UVB313 application |

Test Objectives | Real outdoor environment simulation | Rapid screening/Extreme condition assessment |

Typical Industries | Automotive coatings, building facades, photovoltaic panels | Plastic additive verification, military materials testing |

Test Cycle | Medium and long cycle (hundreds to thousands of hours) | short cycle (tens to hundreds of hours) |

Damage Type | photooxidation, micro-cracking, color change | embrittlement, pulverization, molecular chain fracture |

Model | UV-SI-260 |

Internal Dimension (mm) | 450*1170*500 |

Overall Dimension (mm) | 610*1330*1470 |

Specimen Holder Size(mm) | 75*150 |

Specimen Capacity | 56 Pieces |

Irradiation Source | Fluorescent UV lamps (8) - 40 W |

Temperature Range | Ambient ~ 90 ℃ ±2℃ |

Black Panel Temperature (BPT) | 35 ~ 80 ℃ |

Humidity Range | ≥95% RH |

Bandwidth | 290 ~ 400nm |

Irradiance Control | 0.3~20 W/㎡ |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Distance of Specimen and lamp | 50mm |

| |

|

|

As an industry-leading manufacturer, the LIB Series UV aging machines have three key advantages:

UVA340 and UVB313 mixed programming use, can simulate different latitude/season UV intensity distribution. The fluctuation of ultraviolet intensity in the experimental cabin is controlled within ±2%, which is 5 times better than the industry standard.

"Light-heat-humidity" collaborative control:integrated temperature (RT~90℃), humidity (≥95%RH) and spray module, support ASTM G154, ISO 4892 and other 12 international standards.

Equipped with LIB PLC controller, it supports real-time analysis of test data, anomaly warning and automatic generation of reports. Remote monitoring reduces manual intervention.

Leave a message below to get the "UV Aging Test Chamber White Paper". LIB's full range of UV aging chambers can enjoy three years of extended maintenance services and free spectrum calibration training.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español