Harmful gases refer to gaseous pollutants that are more harmful in the atmosphere, mainly including acidic harmful gases and oxidizing harmful gases, such as H2S, SO2, NO2, CL2)

In scientific research and industrial production, in order to evaluate the performance and safety of materials, products and environments in noxious gas environments, mixed noxious gas flow chambers have become an indispensable tool. Let's take a closer look at it through the following 5 steps.

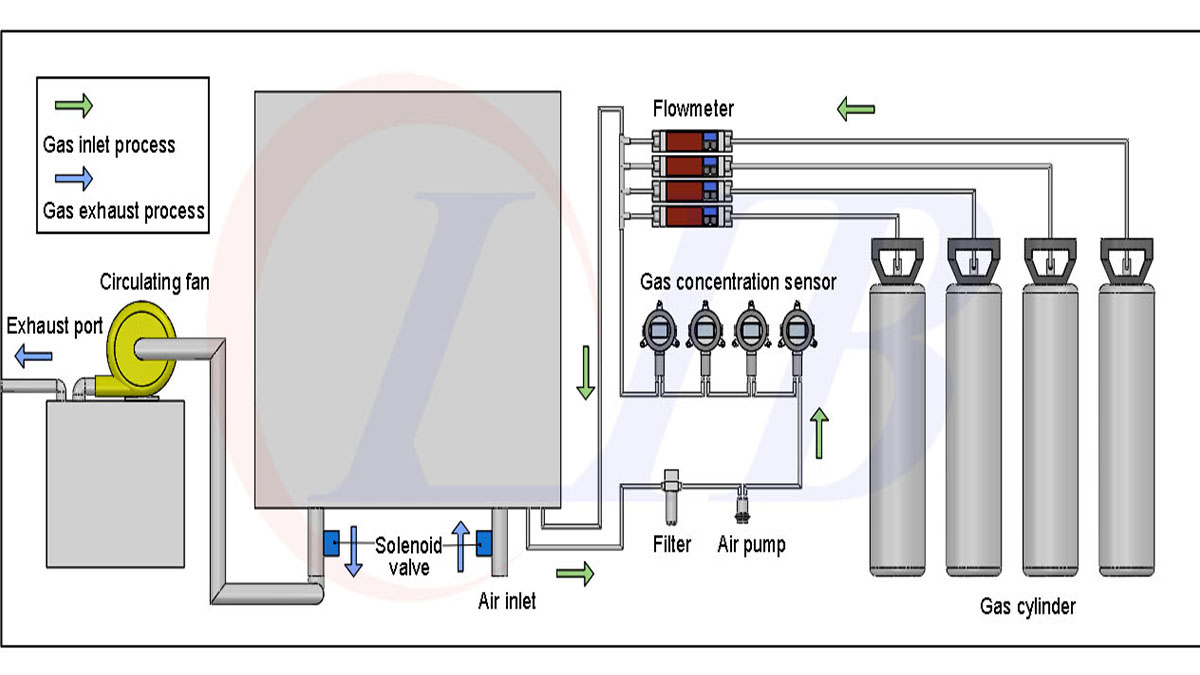

The mixed noxious gas flow chamber usually consists of a robust housing, gas supply system, monitoring and control system, and safety protection facilities. The noxious gas test chamber is made of corrosion-resistant, high-strength stainless steel SUS304 material, and the studio material is anti-corrosion treatment. The stainless steel surface of the studio is attached with a layer of glass steel, which can prevent corrosion and enhance the robustness of the equipment. The gas supply system accurately introduces various noxious gases according to the set value. The noxious gas probe will detect the concentration of the gas in the work room and will stop releasing the gas into the work room when it reaches a preset value.

In addition to gas, the test chamber can also control the temperature, humidity and other parameters in the chamber, and automatically adjust according to preset conditions. The LIB noxious gas flow chamber ensures the sealing of the chamber during the test: concave and convex design, silicone seal, electromagnetic lock and other devices, and gas discharge device after the test to ensure the safety of operators and the cleanliness of the working environment.

Its working principle is based on the physical and chemical properties of gases. First, different noxious gases are delivered to the test chamber in predetermined proportions through the gas supply system. Then, using a mixing device, such as a fan, agitator or special gas mixing chamber, the various gases are fully mixed. The sensor in the monitoring system will continuously collect the relevant data in the chamber and transmit it to the control system. The control system adjusts the gas supply and environmental conditions according to the set parameters, such as gas concentration, temperature and humidity, to maintain a stable test environment.

Configuring noxious gas mixtures requires accurate metering and control equipment. A common approach is to use a flow controller to regulate the flow of each gas, thereby achieving the desired gas concentration ratio. In IEC60068-2-60 standard, Mixed gases are specified, such as SO2: (0.5±0.1) X10-6vol, H2S: (0.1±0.02) X10-6vol. At the same time, it is also necessary to consider the compatibility and reactivity of gases to avoid dangerous chemical reactions during the mixing process.

The performance evaluation of mixed noxious gas flow chamber is mainly based on accuracy, stability, repeatability and uniformity. Accuracy refers to the closeness of the actual measured gas concentration to the set concentration; The stability reflects the ability of the test chamber to maintain the stability of gas concentration and environmental conditions during long-term operation. Repeatability means the consistency of multiple test results under the same conditions. Uniformity examines whether the gas concentration is evenly distributed at different locations in the chamber. These indicators are essential to ensure the reliability and validity of test results.

Safety is always a top priority when using a mixed noxious gas flow chamber. The operator must receive professional training and be familiar with the operation process and emergency treatment measures of the test chamber. Because the gas corroded by the gas is noxious, the gas during the test shall not be discharged into the atmosphere at will, and it is especially necessary to pay attention not to leak into the room.

Before carrying out the test, carefully check the tightness of the equipment and the effectiveness of the safety device. Regular maintenance of the test chamber, including cleaning, calibrating sensors, replacing filters and checking gas lines, can extend the service life of the equipment and ensure its stable performance.

In summary, through these 5 steps, we have a comprehensive and in-depth understanding of the mixed noxious gas flow chamber. It plays an important role in materials science, environmental protection, electronics industry and other fields, providing strong support for ensuring product quality, promoting scientific research and protecting the environment.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español