The IP code waterproof test in the testing of automotive parts and other products is used to verify the tightness of the product and provide the reliability basis of product quality. IS016750, DIN40050, IS020653 series waterproof test the most severe grade is IPX9K. Besides that,various electronic products, auto parts, machinery and equipment operate under different environmental conditions, facing a variety of severe tests. Self-evidently, the IPX9K test equipment is important, which is used to simulate the spray impact under high temperature and high pressure environment to check the protection performance of the product.

The IPX9K test equipment is a device specifically designed to test the IPX9K protection level. IPX9K protection rating means that the product can maintain normal operation in the environment of high temperature and high pressure water injection, free from water intrusion and damage. This level of protection is usually suitable for some special application scenarios, such as auto parts, outdoor equipment, industrial machinery, etc., which may face harsh environments such as high pressure spray, high temperature and high humidity during use.

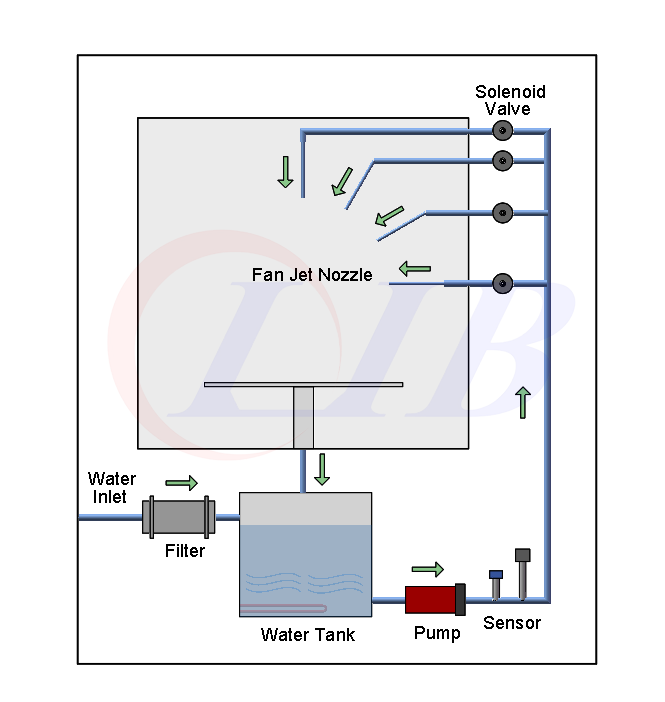

IPX9K test equipment is mainly composed of chamber, water spraying system, heating system, control system, etc. The chamber is made of SUS304, with good corrosion resistance and sealing. The spray system is composed of several high-pressure nozzles, which can produce high temperature and high pressure water injection. The heating system is used to heat the water to the required temperature. The control system is used to control temperature, pressure, injection time, etc.

1. Test conditions

The IPX9K protection test standard requires testing under high temperature and pressure. Specifically, the test water temperature should be between 80 ° C ±5 ° C, and the injection pressure should be between 8000kPa and 10000kPa. When testing, the product should be mounted on a specific shelf to ensure that the water spray can evenly cover the surface of the product.

2. Test method

The IPX9K protection test was performed by means of injection. During the test, the product is placed in the workroom, and the water spraying system is started to spray high temperature and high pressure water to the surface of the product. The angle and distance of the water spray should meet the standard requirements to ensure the accuracy of the test. The test time is usually 30 seconds, and the injection time is 5 seconds in each direction, a total of four directions 0°,30°,60°,90°.

3. Criteria

The criteria for IPX9K protection testing are mainly determined based on the performance and appearance of the product after testing. If the product can operate normally after the test, there is no leakage, water seepage, damage and other phenomena, it is considered that the product meets the requirements of IPX9K protection class. Otherwise, it is considered that the product does not meet the requirements.

The working principle of the IPX9K test equipment is mainly to heat the water to the required temperature through the heating system, and then pressurize the water to the required pressure through the high pressure pump, and finally spray the high temperature and high pressure water to the product surface through the nozzle. During the test, the control system will monitor the parameters of the test equipment in real time, such as temperature, pressure, injection time, etc., and carry out automatic control according to the set program.

The water circulation system of IPX9K test chamber usually has the following characteristics:

1. Water Source:

- Water requirements: It is generally recommended to use pure water or distilled water to reduce the impact of impurities in the water on the equipment and test results, to prevent problems such as nozzle blockage or the formation of scale in the equipment.

2. Cycle process:

- Pumping: The water in the tank is removed through the pump. The pump is the power source of the water circulation, usually using a pump with a certain power and pressure, such as the high pressure and high temperature piston pump imported from Italy, to meet the high water pressure requirements required by the IPX9K test.

- Recovery: The sprayed water will flow back into the tank, completing a water cycle.

3. Related systems and functions:

- Filter device: In order to ensure the cleanliness of circulating water and prevent impurities from damaging parts such as nozzles and pumps or affecting the test effect, a filter device may be installed in the water circulation system to filter impurities in the water.

When using the IPX9K test chamber, the water circulation system should be correctly operated and maintained in accordance with the operating instructions of the equipment to ensure the performance of the equipment and the reliability of the test results. Automatic water circulation system can not only save water, reduce test costs, but also ensure the stability and consistency of test conditions, and facilitate the maintenance and management of equipment.

As an important protective testing equipment, IPX9K test equipment plays an important role in product quality control and reliability verification. Through in-depth understanding of IPX9K test equipment and its related protection test standards, this equipment can be better applied and the protection performance and quality of products can be improved.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español