In modern society, all kinds of electronic products, electrical equipment and outdoor goods are filled with our life and work. Whether it is portable electronic devices such as smartphones and smart watches, or automotive electronic components, outdoor lighting fixtures, etc., their normal operation and service life can be threatened by water. In order to ensure that these products maintain good performance and reliability even when in contact with water, the detection of water resistance becomes essential. The water ingress test chamber is the key tool to evaluate the waterproof ability of the product.

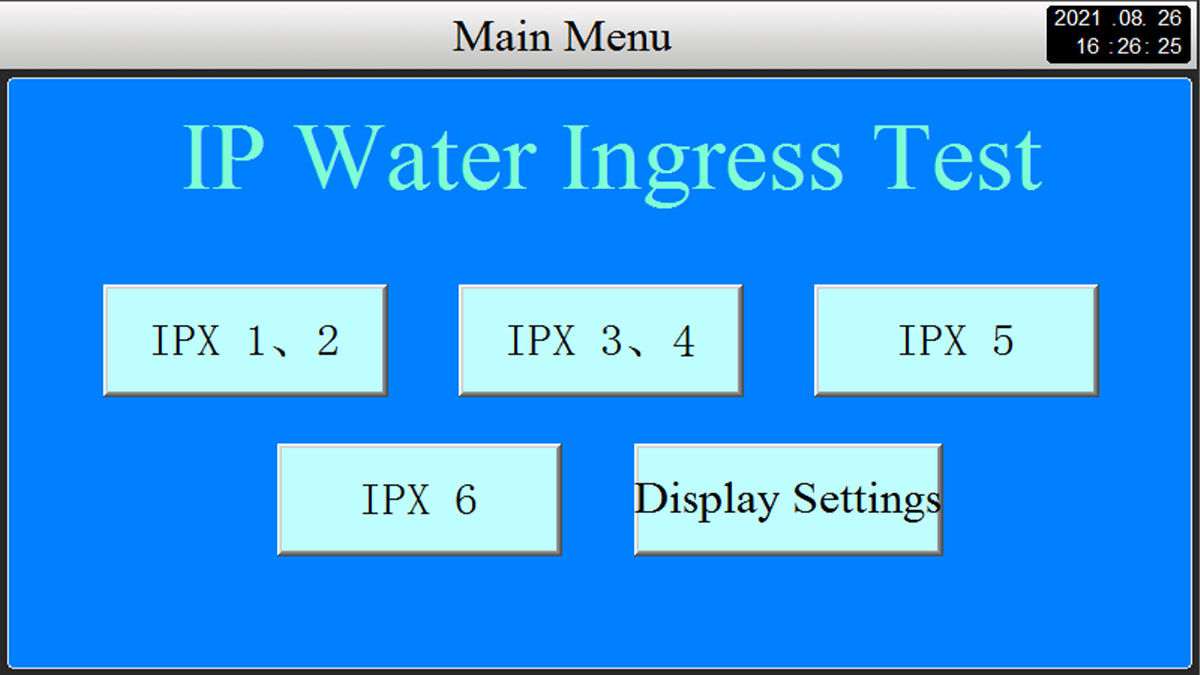

The water ingress test chamber has a broad definition that can cover almost all the waterproof classes in IEC60529. In this paper we mainly discuss the 6 waterproof levels IPX1 to IPX6.

The IPX1 waterproofing test focuses on simulating vertical dripping. In the test, the product is placed in a specific position to receive water droplets falling vertically at a specified rate. This level of testing is relatively basic and mainly applies to some products that do not require high water resistance, but may still occasionally experience vertical dripping, such as small indoor appliances. Through the IPX1 grade test, we can initially understand the product's ability to resist slight vertical dripping, and provide reference for subsequent waterproof improvement.

The IPX2 grade test increases the tilt Angle consideration on the basis of the IPX1. The product needs to withstand dripping water at a 15° tilt. This test is more closely suited to situations that may occur in real use, such as devices placed on slightly inclined surfaces. For products that may come into contact with water under inclined conditions, such as outdoor sensors installed in inclined positions, the IPX2 rating helps to assess the reliability of their water resistance.

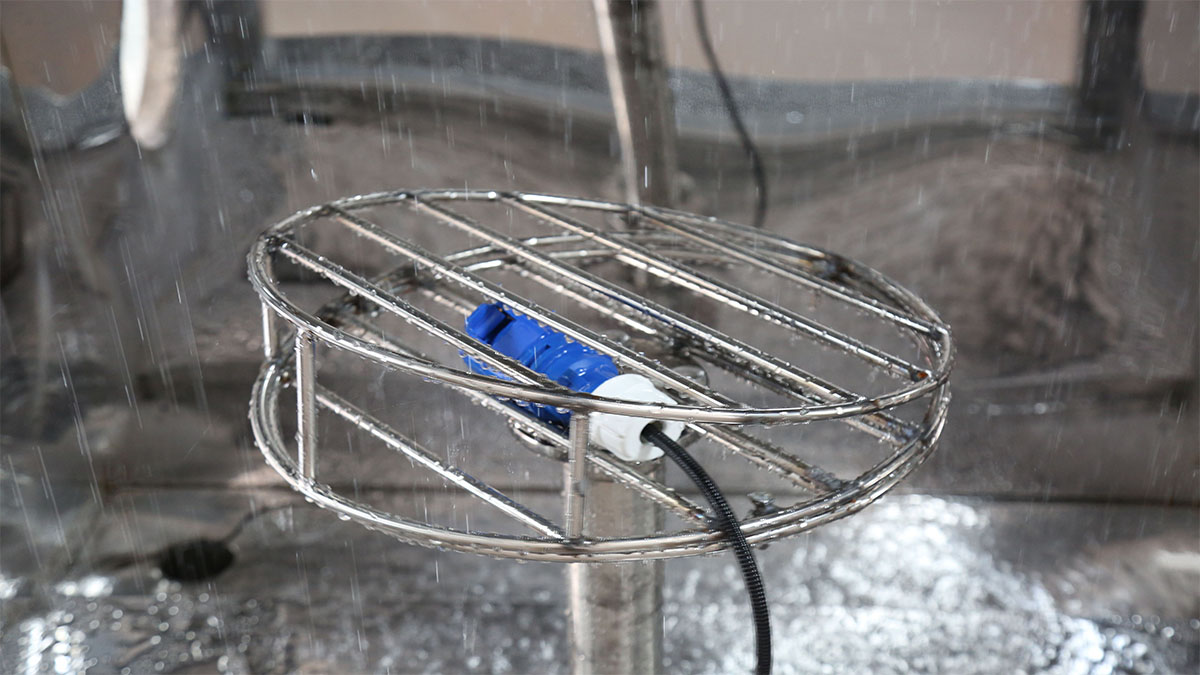

The test of IPX3 grade adopts the way of swinging pipe rain. The product will be sprayed with water from different directions in the test chamber to simulate the scene of rain splashing. This level of testing puts higher requirements on the shell sealing and surface protection capabilities of the product. Like outdoor audio equipment, some sports cameras, etc., they may encounter rain splash in use, and IPX3 grade tests can verify their waterproof performance in this case to ensure normal work.

The IPX4 test further increases the intensity and range of the water splash. The pendulum type of rain is also used, but the speed and volume of water flow are increased. This is a more severe test for the waterproof structure and sealing performance of the product. Suitable for such as the instrument panel of electric bicycles, some outdoor communication equipment, etc., these products may face more intense water splashing environment in actual use, through the IPX4 grade test can guarantee its stability in harsh conditions.

The IPX5 test uses a powerful spray gun, and the product is directly subjected to a high-speed jet of water. This level of testing is mainly for products that need to work in more challenging water environments, such as industrial distribution chamberes, some outdoor power tools, etc. Strong water shocks can test the robustness of product housings and interfaces and the effectiveness of seals.

The IPX6 test increases the intensity of the water flow to the extreme. Powerful high-pressure water is sprayed directly onto the product, and only products with excellent water resistance can pass this level of rigorous testing. It is often used in products with high waterproof requirements, such as Marine monitoring equipment, key components in hydraulic engineering, etc. These products work in extreme water environments and must have top waterproof capabilities.

In the product development and production process, the role of water ingress test chamber can not be underestimated. In the development phase, it can help engineers identify potential waterproofing vulnerabilities in product design so that targeted improvements can be made. For example, tests may find that the seal of a certain interface is not tight enough, or that the material of a certain shell is prone to aging and water seepage after long-term contact with water. Based on these findings, engineers can adjust the design scheme, choose more suitable sealing materials, and optimize the structural design to improve the waterproof performance of the product.

In the production process, the water ingress test chamber can be used as an important means of quality detection. Each batch of product can be tested for water resistance to ensure that it meets design requirements and quality standards. This not only helps to improve the overall quality level of the product, but also enhances consumer trust and satisfaction with the product.

Moreover, the application of water ingress test chamber is also of great significance for the improvement of market competitiveness of enterprises. In the market, products with good waterproof performance are often more popular with consumers. For example, in the group of outdoor sports enthusiasts, sports watches and cameras with excellent waterproof performance can be used normally in a variety of adverse weather conditions, so it is more attractive. Through the rigorous testing of the water ingress test chamber, companies are able to give higher added value to their products, so as to stand out in the competitive market.

In addition, with the continuous progress of science and technology and changes in market demand, water inlet protection test chamberes are also constantly developing and innovating. The new test chamber may have more precise water flow control, smarter test procedures, and more comprehensive data acquisition and analysis capabilities. These improvements make the test results more accurate and reliable, but also improve the efficiency and convenience of the test.

In summary, the water ingress test chamber plays a crucial role in ensuring the waterproof performance of the product. It not only provides a scientific testing basis for product development and production, but also promotes enterprises to continuously improve product quality and market competitiveness. In the future, with the continuous development of technology and the continuous expansion of application scenarios, the water ingress test chamber will continue to play an important role, bringing us more waterproof products with excellent performance and reliability.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia