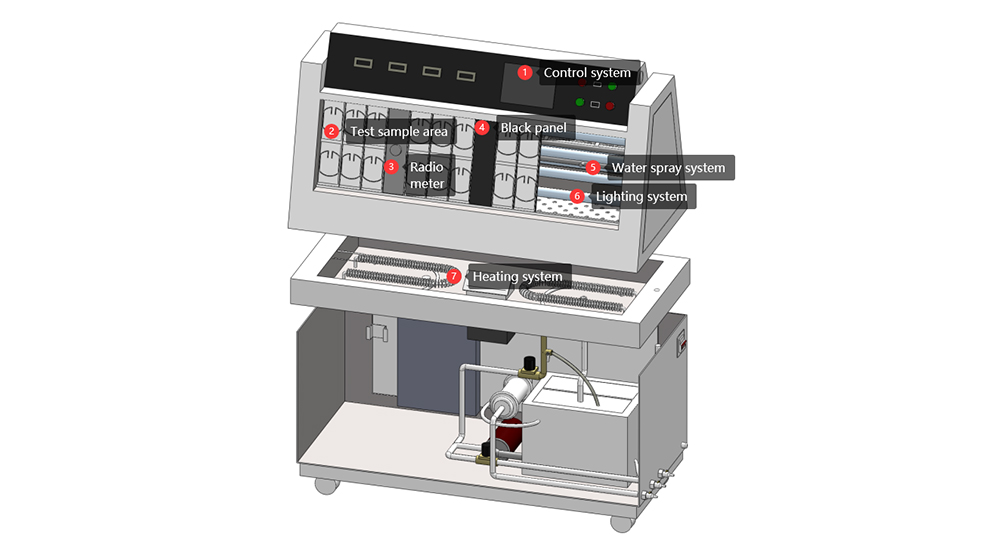

UV Light Fastness Test Chamber Features and Benefits

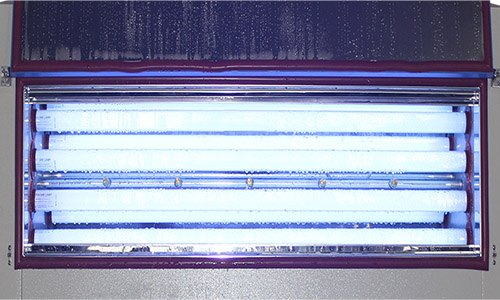

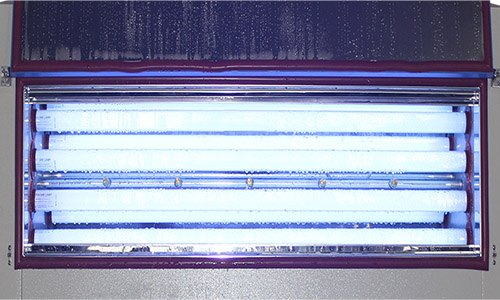

1. LIB Industry uv weathering test machine equipped with UVA-340 wavelength range of 315~400nm, can better simulate the ultraviolet part of daily sunlight, UVB-313 wavelength range of 280~315nm, high energy, the aging effect on the material is stronger. Spectral power distribution does not change with lamp aging, even when used for up to 5000 hours.

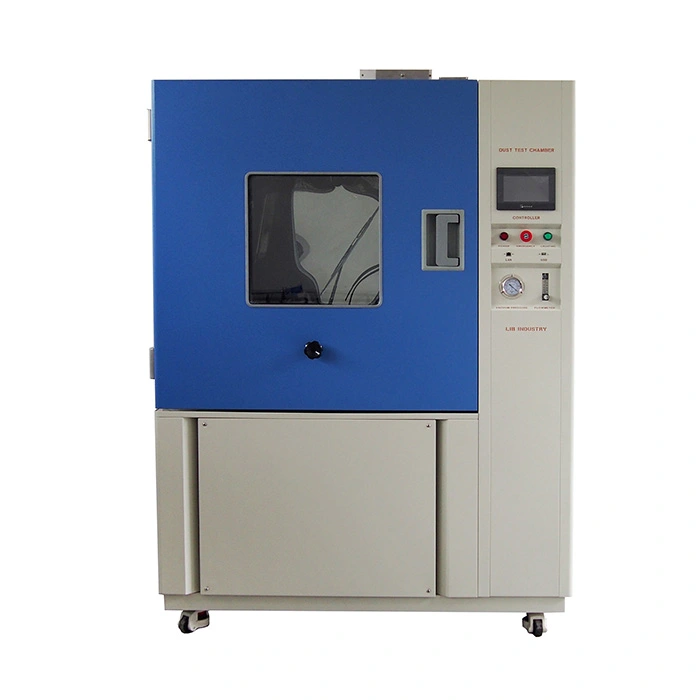

2. The chamber shell adoptsA3 steel plate. The internal workroom is made of SUS304 corrosion-resistant material, which can prevent workroom from being corrosed due to long-term exposure to ultraviolet light, moisture, etc.

3.The UV light fastness test chamber is capable of complex environmental simulation, including factors such as ultraviolet light, humidity, temperature and rain, to restore the most realistic use scenario of the test piece.

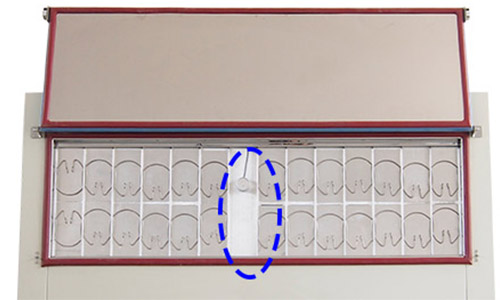

4. The standard sample holder can hold up to 56 75mm*150mm samples at a time, which greatly improves the test efficiency. Custom sample holders for profile-shaped test pieces are also supported.

UV Light Fastness Test Chamber Specifications

Model | UV-SI-260 |

Internal Dimension (mm) | 450*1170*500 |

Overall Dimension (mm) | 610*1330*1470 |

Specimen Holder Size(mm) | 75*150 |

Specimen Capacity | 56 Pieces |

Irradiation Source | Fluorescent UV lamps (8) - 40 W |

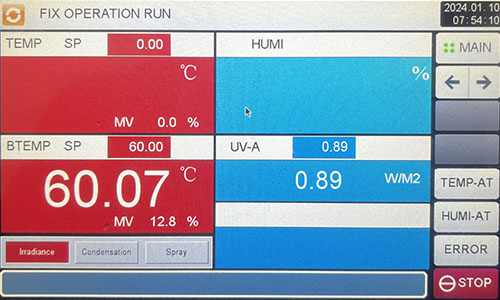

Temperature Range | Ambient ~ 90 ℃ ±2℃ |

Black Panel Temperature (BPT) | 35 ~ 80 ℃ |

Humidity Range | ≥95% RH |

Bandwidth | 290 ~ 400nm |

Irradiance Control | 0.3~20 W/㎡ |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Distance of Specimen and lamp | 50mm |

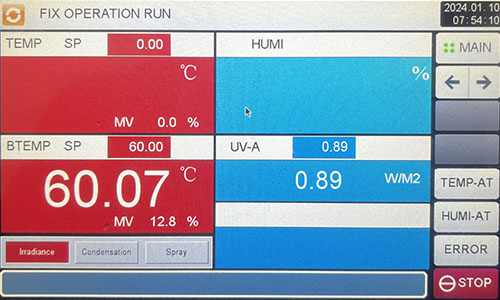

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water Supply System | Automatic water supply, Water purification system |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Configuration of UV Light Fastness Test Chamber

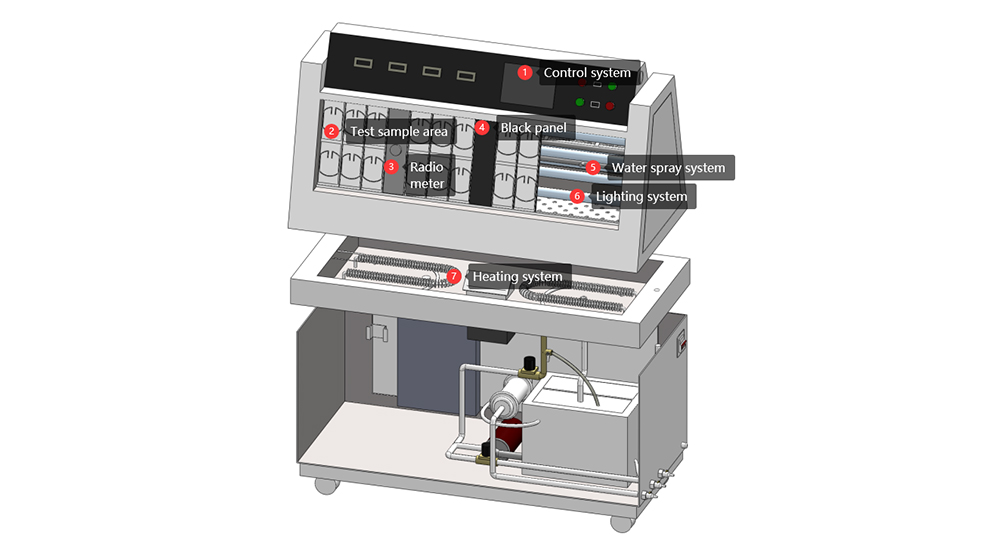

① Control system | Set and adjust the test temperature, irradiation time, light intensity, spray time and cycle and other parameters. The UV test chamber is equipped with four current display devices on the control system, which can detect the UV lamp failure or light source attenuation in the first time.

|  |

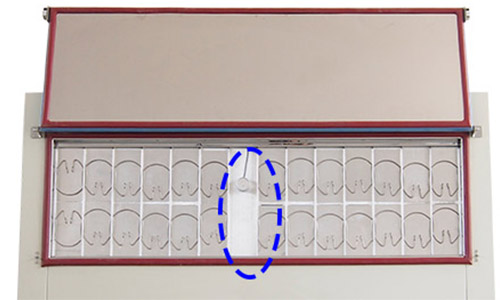

② Test sample area | Place the sample under test. Flat Specimen Holders (aluminum panels with rings). Customize special holder according to different specimens.

|  |

③ Radiometer | Measure the irradiation intensity of the ultraviolet lamp in the test chamber. At the same time, it can also find the aging and damage of the lamp in time. |  |

④ Black panel | Simulate the light and temperature conditions that the sample is subjected to in the actual use environment. |  |

⑤ Water spray system | The spray system can be set according to different spray modes, such as continuous spray, intermittent spray, etc. |  |

⑥ Lighting system | Ultraviolet lamps are used, such as UVA lamps (wavelength 315-400nm) and UVB lamps (wavelength 280-315nm). Different types of lamps can simulate different wavelengths of ultraviolet radiation to meet the test needs of different materials. |  |

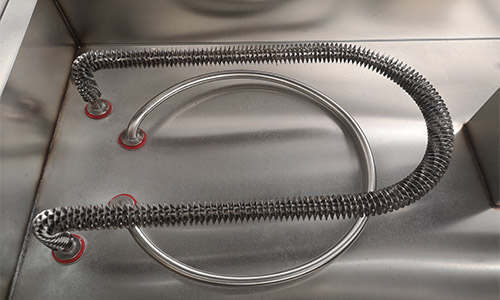

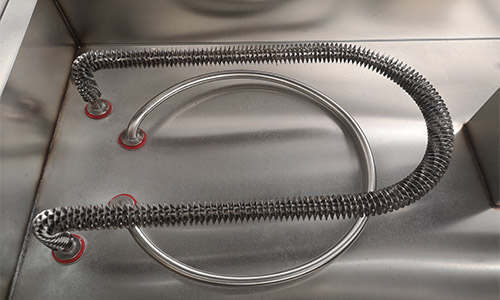

⑦ Heating system | Using electric heating, through a heating element at the bottom of the workroom, there is water at the bottom, which generates steam when heated. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español