A UV weathering test chamber is a laboratory device used to simulate the effects of ultraviolet (UV) radiation, temperature changes, and water exposure on materials, products, or coatings in a natural environment. This chamber accelerates the aging process of test samples, allowing for the assessment of their durability and reliability in outdoor conditions within a shorter period. The following are the main components, working principles, and applications of a UV weathering test chamber:

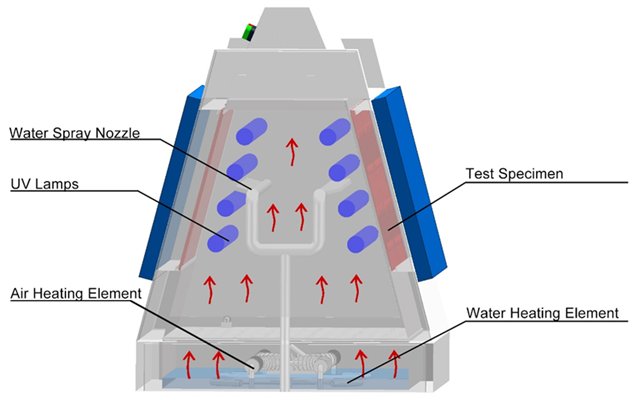

1、Light Source:UV Lamps: Generate UV radiation to simulate the UV portion of sunlight.Sometimes includes visible light and infrared lamps to simulate a broader spectrum of sunlight.

2、Sample Rack:Holds the samples to be tested; the rack can rotate to ensure even exposure to light.

3、Water Spray System:Simulates the impact of rain on the samples and can be controlled automatically or manually to adjust the spray cycle.

4、Control System:Used to set and adjust test parameters such as light exposure time, spray cycle, and temperature.

5、Temperature Control System:Includes heaters and cooling devices to simulate daily temperature variations.

6、Humidity Control System:Sometimes includes a humidifier to simulate high humidity environments.

1、UV Radiation:The chamber uses UV lamps to expose samples to UV radiation, simulating the UV portion of sunlight.

2、Temperature Changes:Heaters and cooling devices simulate daily temperature variations, accelerating the aging process.

3、Water Spray:The spray system simulates the impact of rain, assessing the durability of samples under wet conditions.

4、Cyclic Testing:Pre-set programs control the cycles of light exposure, spraying, and temperature changes, simulating the periodic variations of the natural environment.

1、Material Testing:Evaluates the aging resistance of plastics, rubber, coatings, textiles, and other materials under UV radiation.

2、Coating Testing:Detects aging phenomena such as fading, chalking, and cracking of coatings under the influence of UV and humidity.

3、Product Quality Control:Ensures that products meet the durability requirements for outdoor use during design and production.

Common Test Standards:

ASTM G154: Standard Practice for Operating Light- and Water-Exposure Apparatus (Fluorescent UV, Water).

ISO 4892-3: Plastics - Methods of exposure to laboratory light sources - Part 3: Fluorescent UV lamps.

GB/T 16422.3: Plastics - Methods of exposure to laboratory light sources - Part 3: Fluorescent UV lamps.

A UV weathering test chamber is an indispensable tool in product development, quality control, and material science research. It helps manufacturers and researchers predict the lifespan and behavior of products in outdoor environments.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia