Walk In Humidity Chamber Features and Benefits

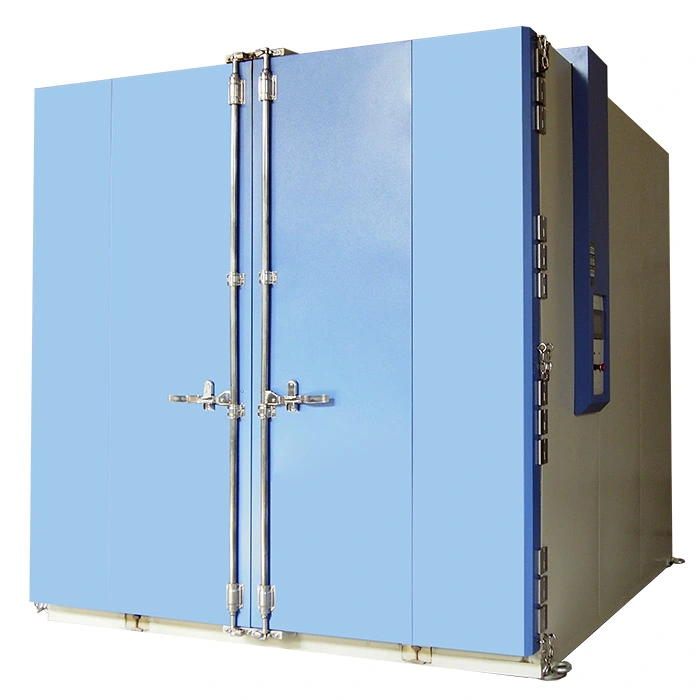

1. Easily accommodate large products, parts, components or finished products for testing, such as large mechanical equipment, aerospace parts, automotive vehicles or large electronic equipment, providing an ideal test environment.

2. The spacious internal space allows multiple samples to be tested at the same time, which greatly improves the test efficiency, especially for the quality detection and screening of batch products by production enterprises.

3. Equipped with advanced temperature and humidity control system and high-precision sensor, it can accurately control the temperature and humidity in the test chamber to ensure the stability and consistency of the test environment.

4. Walk in humidity chamber can be customized according to the specific needs, including internal dimensions, temperature and humidity ranges, control systems, cooling and heating methods, etc.

Walk In Humidity Chamber Specifications

Model | TH-100 | TH-225 | TH-500 | TH-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 1000L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

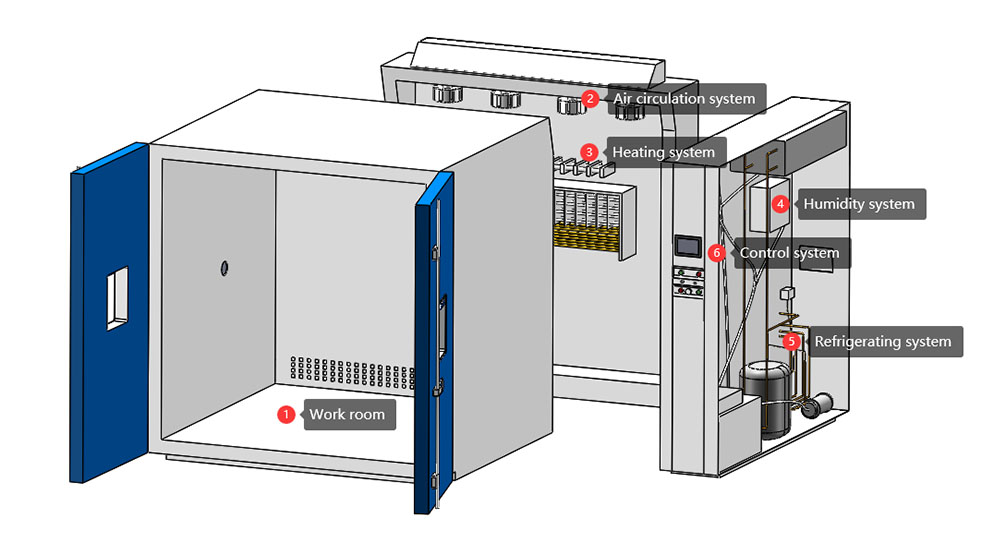

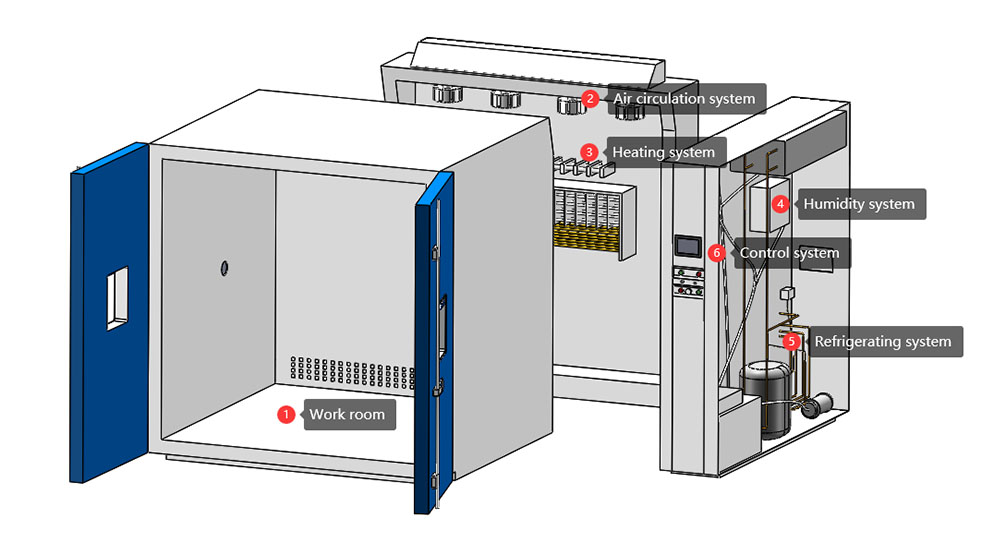

Configuration of Walk In Humidity Chamber

| 1. Workroom | Chamber shell adopts 4MM A3 steel plate with high mechanical strength. 10 CM insulating polyurethane foam reduces heat exchange between the inside of the test chamber and the outside environment. The workroom space is large to accommodate large samples or multiple samples for testing at the same time. The size of the inner chamber is subject to user's requirement. Temperature and humidity sensor are for real-time monitoring of temperature and humidity changes in the chamber. The workroom is equipped with lightings.

|

|

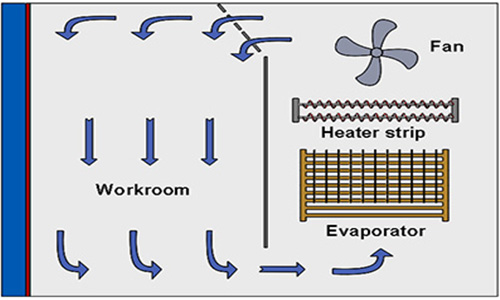

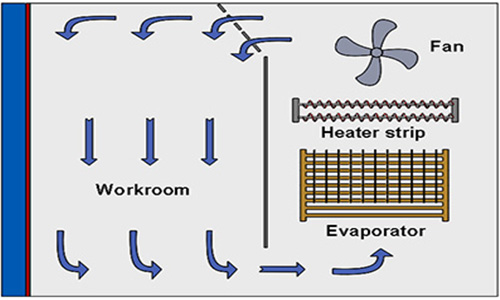

| 2. Air circulation system | Centrifugal fans are installed in the walk in humidity test chamber to circulate air and make the temperature and humidity distribution in the chamber more uniform. |  |

| 3. Heating system | Resistance wire heating. The temperature in the chamber is raised by heating the air. The power and distribution of the heater is designed according to the size and temperature control requirements of the chamber. |  |

| 4. Humidity system | Steam humidification. Fast humidifying speed and high humidity control precision. |  |

| 5. Refrigerating system | Compressor refrigeration. The refrigeration device includes a compressor, condenser, evaporator, throttling device and other components, which absorb the heat in the test chamber and reduce the temperature through the circulation of the refrigerant. |  |

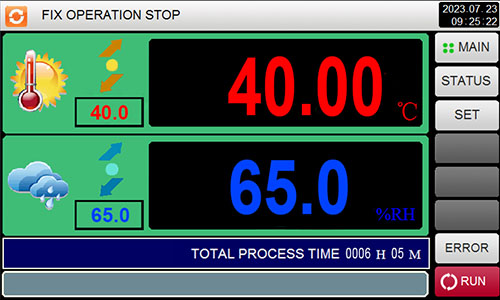

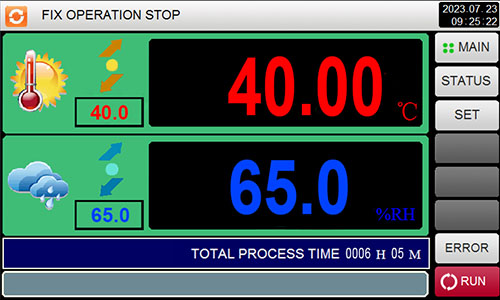

| 6. Control system | Programmable controller (PLC). The operator can set the temperature, humidity, test time and other parameters of the test chamber through the control panel to view the running status and real-time data of the test chamber. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español