The cyclic corrosion test chamber is a commonly used experimental equipment designed to simulate the salt spray corrosion conditions found in natural environments.

1.Improved and upgraded from traditional salt spray chambers, it can simultaneously conduct salt spray tests, humidity tests (high temperature and high humidity, low temperature and low humidity), and drying tests (hot dry, dry).

2.Corrosive solution from the storage tank is transported to the balance tank via a corrosion-resistant pump, maintaining the liquid level equal between the balance tank and the nozzles.

3.Compressed air is directed to the nozzles after being humidified and cooled in the saturation tank.

4.The nozzles atomize the corrosive solution into corrosive mist, which is evenly distributed throughout the test chamber with the help of the diffusion tower.

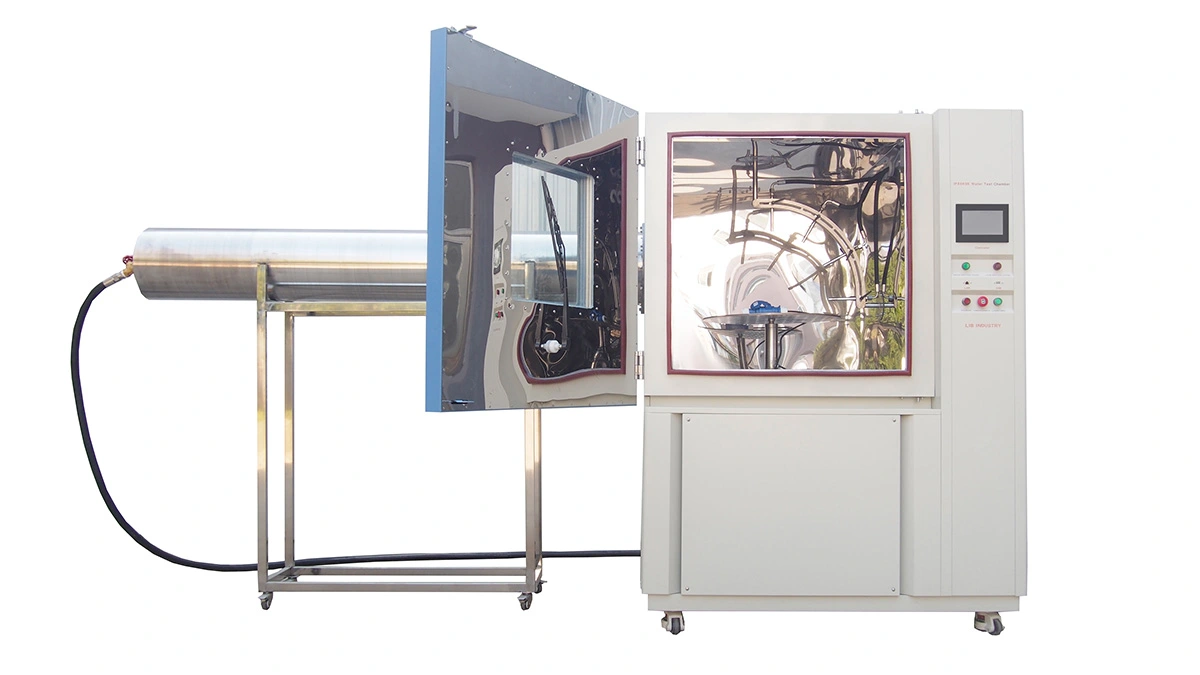

5.The chamber cover is designed with a double-layer structure and large windows; the inner layer is made of CPVC material, smooth, corrosion-resistant, and heat-resistant. 6.The angle of the cover is designed according to standards to ensure that steam droplets fall into the test chamber.

7.Steam is transported to the test chamber to maintain the temperature at the set value.

After the salt spray process is complete, the equipment automatically initiates the exhaust method to avoid deviation from temperature standards in the salt spray system and environment.

8.The main body structure of the equipment is made of stainless steel and engineering plastics, corrosion-resistant and with good load-bearing capacity.

9.The machine runs on universal casters with lifting feet, making it easy to move and position.

10.The chamber cover adopts a dual-cylinder design for automatic lifting and lowering.

11.The chamber cover is equipped with large transparent windows for easy observation and sample inspection.

12.Dual tower design ensures better propagation of mist inside the test chamber.

13.The atomizing nozzles are made of acrylic material, corrosion-resistant, and are automatically cleaned after the spray test.

14.The testing process with different method combinations can be fully customized to meet various testing standards.

1.The corrosive solution is sprayed into mist by compressed air and envelops the test specimens in the chamber.

2.Testing can be continuous or cyclic.

3.The corrosion resistance level of each specimen is defined by its corrosion time; the longer the time, the better the corrosion resistance.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español