Corrosion, an age-old enemy of metals, steadily eats away at the aesthetics and functionality of numerous products. From automobiles to infrastructure, corrosion can wreak havoc on the durability and lifespan of materials. That's why corrosion testing has become an indispensable part of product development and quality assurance processes.

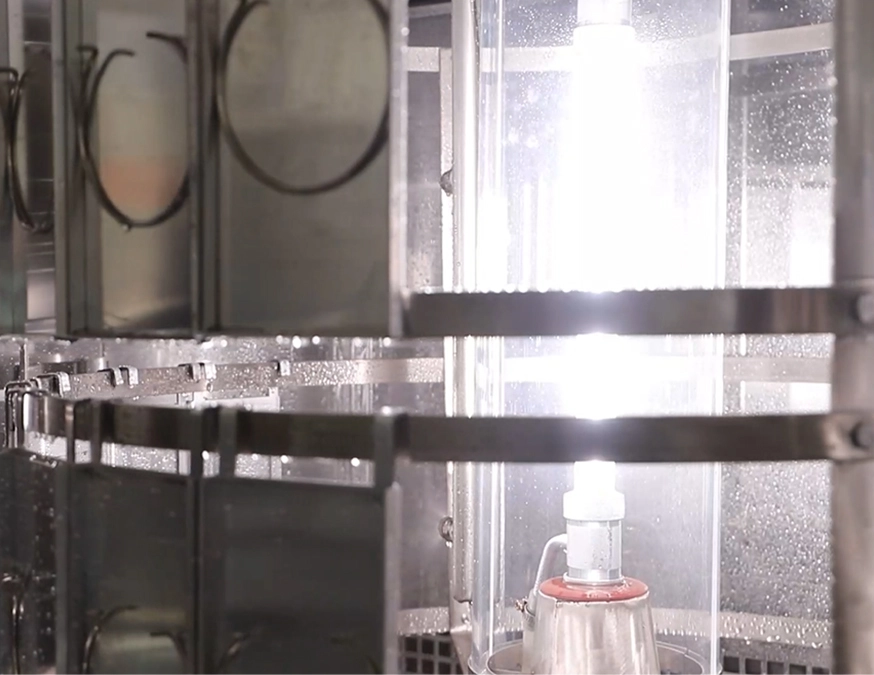

To combat the challenges of corrosion and ensure product durability, engineers and researchers have turned to advanced testing technologies, such as cyclic corrosion chambers. These chambers provide a controlled environment to simulate realistic corrosive conditions, accelerating the corrosion process and helping manufacturers evaluate the performance and suitability of materials.

Replicating Real-world Corrosive Conditions: Cyclic corrosion chambers accurately emulate various environmental factors that contribute to corrosion, such as temperature fluctuations, humidity, salt spray, and periodic wet-dry cycles. By creating specific conditions tailored to the intended application, manufacturers can gather precise data on the behavior and performance of materials, and identify potential weaknesses or areas for improvement.

Accelerated Testing, Reduced Time & Cost: Traditional corrosion testing can be time-consuming and costly, as it relies on natural exposure to corrosive elements. In contrast, cyclic corrosion chambers can provide accelerated testing, mimicking years' worth of corrosion in just a matter of weeks or months. This speeds up the development cycle, allowing manufacturers to bring corrosion-resistant products to market faster while reducing research and development costs.

Improved Product Design & Durability: By subjecting products or components to rigorous testing in cyclic corrosion chambers, manufacturers can identify vulnerabilities early on in the design phase. This enables them to make necessary modifications, select more suitable materials, or apply protective coatings to enhance corrosion resistance. As a result, products can be engineered with higher durability, better service life, and increased customer satisfaction.

Enhanced Quality Assurance: Cyclic corrosion chambers play a pivotal role in quality control, enabling manufacturers to assess the reliability and performance of their products in harsh environments. By subjecting prototypes or batches to rigorous testing, manufacturers can ensure that their products meet or exceed industry standards, regulations, and customer expectations. This helps avoid costly product failures, warranty claims, or safety issues down the line.

Versatile Applications: Cyclic corrosion chambers are not limited to specific industries; they find applications in a wide range of sectors. Whether it's testing automotive parts for resistance to road salts or evaluating marine coatings' durability against salt spray, these chambers can be customized to simulate the specific corrosion challenges faced by different industries. Consequently, manufacturers can tailor their testing protocols to suit their unique needs.

In the realm of corrosion testing, cyclic corrosion chambers have proven to be a game-changer. By replicating real-world corrosive conditions, offering accelerated testing capabilities, and aiding in product design enhancement, these chambers assist manufacturers in producing more durable, corrosion-resistant products. With their versatility and ability to deliver reliable results, cyclic corrosion chambers are indispensable tools in advancing the fight against corrosion and ensuring the longevity of products in various industries.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español