Features and Benefits of IP6K9K Test Chamber

| 1. Versatility: IP6K9K test chamber can meet the waterproof test requirements of IPX6K and IPX9K at the same time, one can complete a variety of test tasks, saving equipment procurement costs and test site space. |  |

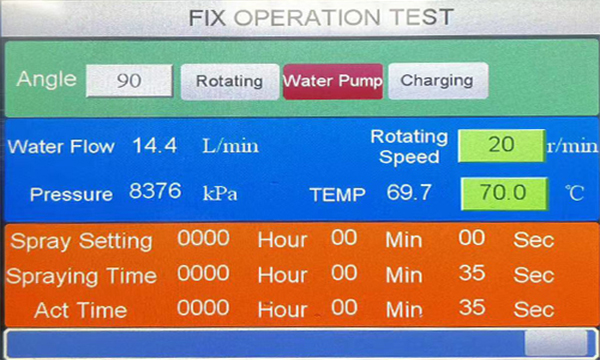

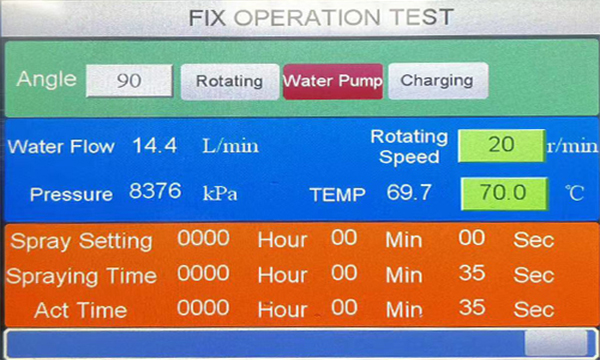

| 2. IPX6K spray pressure up to 1000 kpa (10 kg), water flow rate of about 75±5 (L/min); The IPX9K injection water pressure is 8000-10000kPa (80-100bar), and the spray flow rate is 14-16L /min and water is sprayed at four angles of 0°, 30°, 60° and 90°, with precise pressure and flow control. |  |

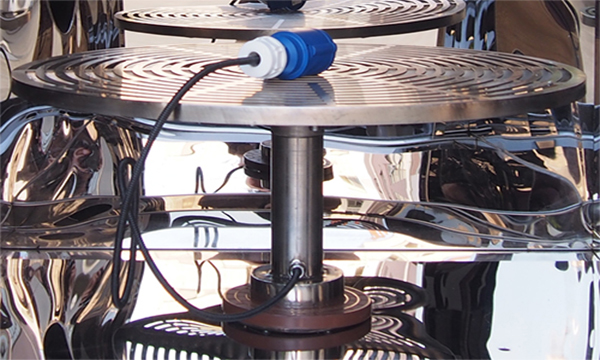

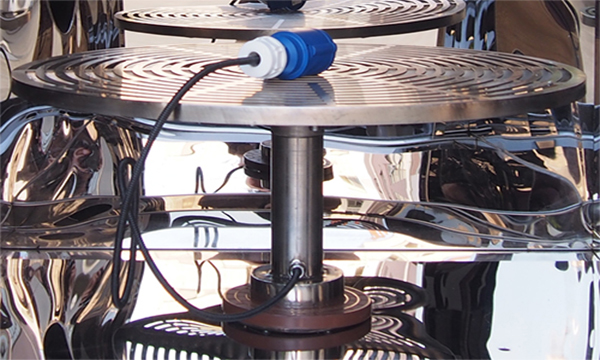

| 3. Sample table adjustable speed, adjustable up and down, with waterproof electric port, adjustable up and down, to meet the test requirements of different sizes and types of samples. |  |

| 4. Automatic control of the water intake of equipment, user can be directly connected to the laboratory faucet, so as to achieve automated testing;Automatic inlet diameter 1/2 inch (13.5MM);Meantime IP6K9K test chamber is equipped with high and low water level alarm, water shortage lights and sound. |  |

Specifications of IP6K9K Test Chamber

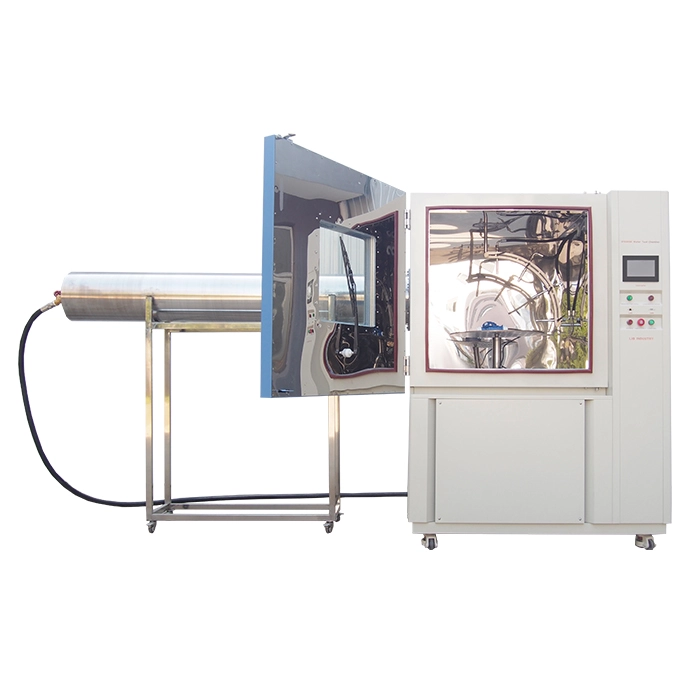

Model | R6K9K-1200 |

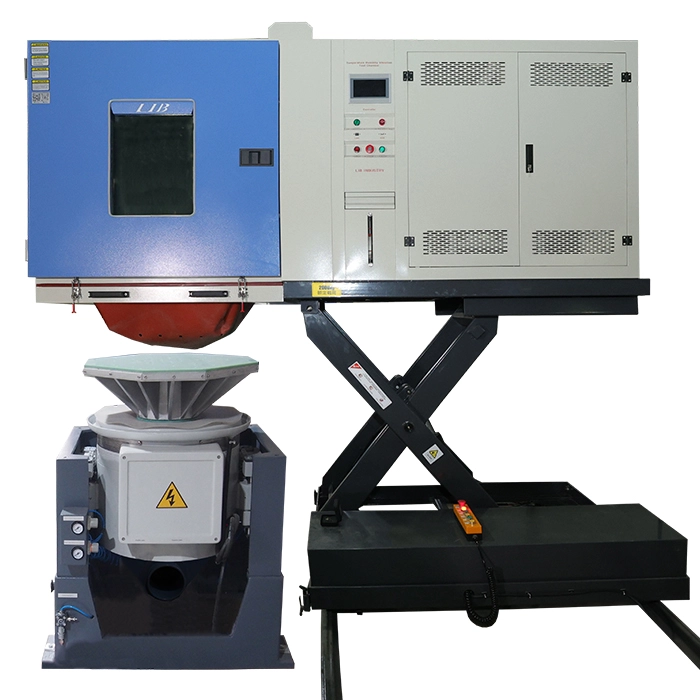

Internal Dimensions (mm) | 1000*1200*1000 D*W*H |

Overall Dimensions (mm) | 1150*3550*2100 D*W*H |

Interior Volume (L) | 1200 |

Parameter | Testing Platform Diameters | 600mm |

Testing Platform Speed | 5±1 r.p.m |

Turntable loads | 50kgs |

Testing Platform Height | 200-400 mm (adjustable) |

IPX6K | Internal Diameter of Nozzle | 6.3mm |

Water Flow Rate | 75 L/min +/- 5% |

Water pressure | 1000 Kpa |

Distance from Water Spraying to Specimens | between 2.5 m and 3 m. |

IPX9K | Water Spray Angle | 0°, 30°, 60°, 90° |

Water Spray Temperature | Ambient ~ +88℃ (Adjustable) |

Spray Nozzle | Four, 30 Seconds each position |

Distance from Water Spraying to Specimens | 10~15cm |

Water Pressure | 8000-10000 Kpa (Adjustable) |

Water Flow Rate | 14L-16L/min |

Temperature Sensor | PTR Platinum Resistance PT100Ω/MV A-class |

Heater Elements | Nichrome heater |

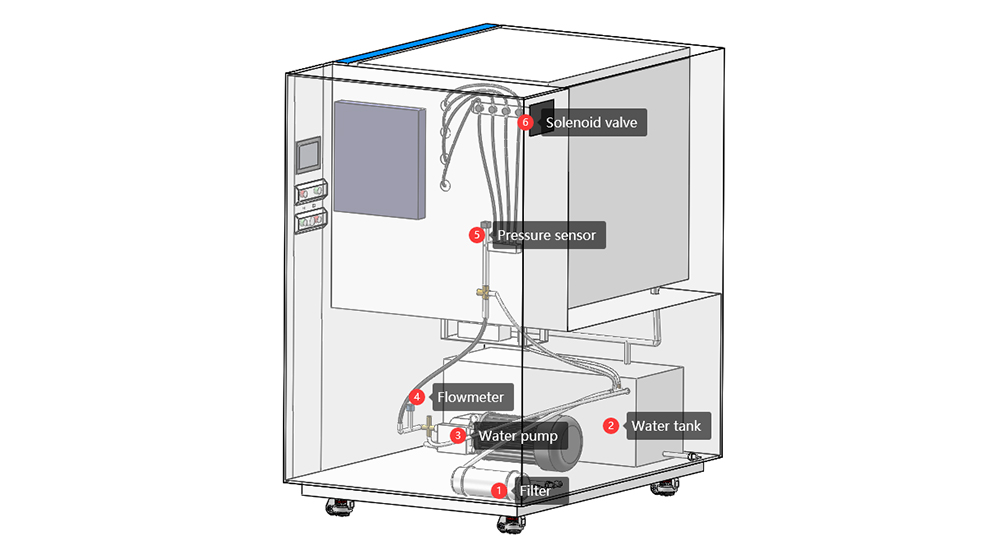

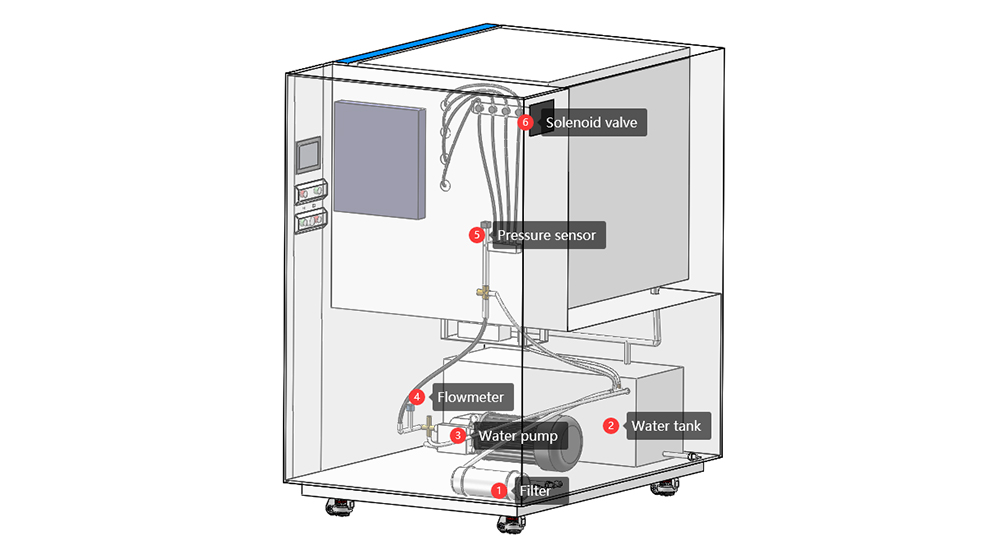

Configuration of IP6K9K Test Chamber

① Filter

Filter impurities, avoid clogging nozzles, protect equipment.

②Water tank

Provide adequate water reserve for the test to ensure continuous water supply during the test.

③Water pump

The water in the tank is pressurized to the sprinkler system so that the water can be sprayed out of the nozzle at a high pressure of 1000 kpa (10 kg), the water flow rate of about 75±5 (L/min) and 8000-10000kPa. Provides a stable water flow (14-16L /min).

④Flowmeter

Measure the water flow in the sprinkler system in real time to ensure that the water flow is in the specified range of 75±5 (L/min) and 14-16 L/min.

⑤Pressure sensor

Real-time monitoring of water pressure, the water pressure signal is converted into electrical signal transmission to the control system. When the water pressure is abnormal, the pressure probe will alarm, which also ensures the safety of the equipment and the operator.

⑥Solenoid valve

According to the test procedure and the command of the control system, control the water channel of the sprinkler system.

The water circulation system in the IPX6K9K test chamber is a closely coordinated system: the chamber is equipped with a water tank, and a liquid level sensor monitors the water level in real time. The water is pumped and pressurized, then sent to the nozzles, where a filter removes impurities. The used water is filtered and returned to the water tank for recycling, thus achieving the goal of saving water, reducing costs, and ensuring the continuation of the test.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español