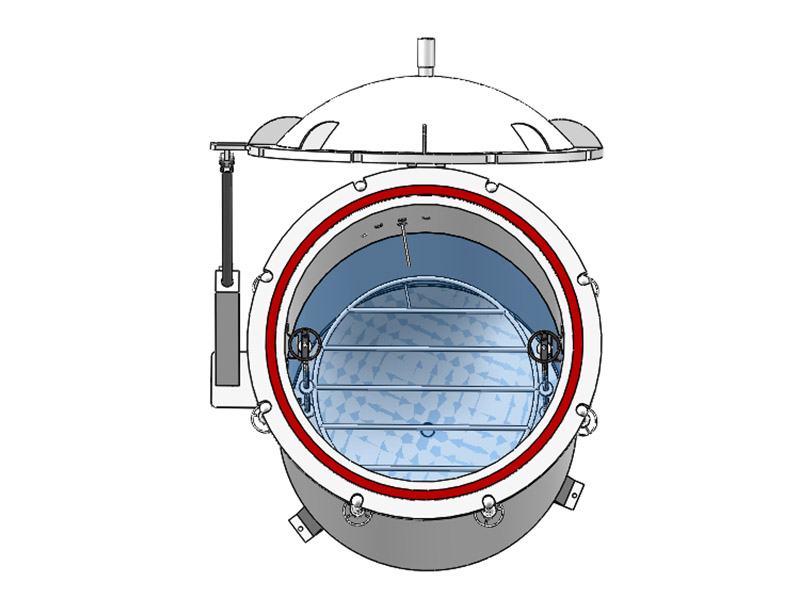

As we all know, many electronic devices today will be waterproof certification as a major selling point, IPX8/IPX7 also often appear in the product advertising slogan, so today we will understand the tools that can carry out IPX7 IPX8 waterproof level test --- water immersion test chamber.

The IPX7 standard means that the product can still maintain normal function after soaking for 30 minutes in a specified water depth (1 meter); IPX8, on the other hand, requires the product to remain waterproof and non-destructive after prolonged immersion (e.g., 4 hours or more) in deeper water (usually specified by the manufacturer). Understanding the differences in these standards helps us test more accurately.

Sample preparation: First, carefully clean the surface of the sample to remove dust, oil and other impurities to ensure that it is dry without moisture residue. Then, the appearance of the sample is thoroughly inspected to record any scratches, cracks, or other defects that may affect the waterproof performance.

Preparations: Check the water level of the water tank and ensure that the water level meets the IPX7 test depth (1 m). Ensure that the water tank does not leak. At the same time, turn on the power supply of the test equipment, enter the setting interface of the control system, and set parameters such as water temperature (usually about 25 ° C at normal temperature) and soaking time (30 minutes) according to the test standard.

firmly fix the prepared sample on the test rack, use the appropriate fixture or fixing device to ensure that the sample will not shift, shake or fall off during the entire test process, and will not cause additional damage due to improper fixing.

record the start time of the test, so as to accurately control the soak time in the future.

pay attention to whether there are abnormal conditions in the sample in the test chamber, such as whether there are bubbles escaping from the gap of the sample, indicating that there may be water intake; Whether there are signs of sample displacement or loosening of fixtures; And whether the appearance of the sample is deformed or damaged.

When the set soaking time of 30 minutes is reached, stop the equipment operation immediately and carefully take out the sample. The sample is thoroughly checked for water resistance according to the pre-established testing procedure.

IPX8 testing is more rigorous than IPX7 testing.

Determine the appropriate water pressure or water depth parameters according to the IPX8 waterproof rating required by the sample.

According to the strictness of IPX8 test, the sample is specially packaged. For example, for some electronic equipment, it may be necessary to add an additional sealed bag on the basis of its original sealing structure, and ensure that the sealed bag is not damaged and sealed well; For samples with interfaces or openings, use a special sealing plug or sealant to seal properly and tighten all sealing caps to ensure that there is no water inside the sample under high water pressure.

carefully put the packaged sample into the test chamber filled with water to ensure that the connection between the sample and the test chamber is tight without leakage, and all sealing parts are in normal working condition to prevent the unstable water pressure caused by the tight connection during the test process, affecting the test result.

Start the test equipment and start the long time immersion test. Because IPX8 tests are long and can last for hours or more, the stability of the device should be monitored regularly (such as every hour) during the test, and the sample should be observed for any changes or abnormal signs.

After the test, the test chamber is slowly drained to avoid damage to the sample due to sudden pressure drop. After the drainage is complete, the sample is carefully removed, the packaging material is removed, and the sample is thoroughly inspected according to strict testing standards and procedures. The inspection contents include whether the sample is flooded inside, and the key components can be observed by disassembling the sample to see whether there are moisture and water marks inside; And whether the functions are normal, such as whether the electronic components are short circuit, open circuit, whether the mechanical parts are flexible, and record the test results in detail.

Through the detailed introduction of the use method of the LIB brand water immersion test chamber in this paper, we deeply realize that in the operation process, whether it is IPX7 or IPX8 level test, strict compliance with the operating specifications of each step is the key to ensure accurate and reliable test results. From the careful preparation before the test, the proper placement of the sample, the accurate setting of the equipment parameters, to the careful observation and monitoring of the test, as well as the proper handling of the sample after the test and the comprehensive maintenance of the equipment, every link can not be underestimated.

If you are interested in the LIB brand water immersion test chamber! Contact our sales team today inquiry@libtestchamber.com for more product information and promotions to start your journey of precise waterproof testing and make your products one step ahead of the water resistance!

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español