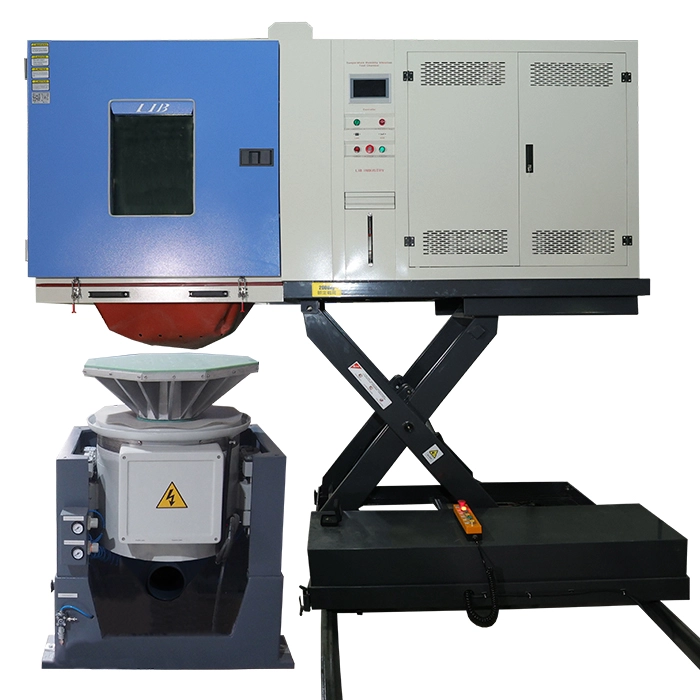

Temperature Shaker Chamber Features and Benefits

1. With high precision temperature, humidity and vibration control system, temperature shaker chamber can more truly simulate the comprehensive environmental conditions faced by the product compared with the effect of a single factor.

2. Temperature shaker chamber has good thermal insulation performance and structural strength,it can run continuously for a long time and is not prone to failure, ensuring the reliability of test results.

3. Intelligent control system and clear and intuitive operation interface, operators can easily complete a variety of complex test settings and operations.Temperature shaker chamber can record the temperature, humidity, vibration and other data.

4. Widely used in product quality control and R&D process in many industries such as electronics, aerospace, automobile, navigation, communication, medical equipment, etc.

Temperature Shaker Chamber Specifications

Model | THV-225 |

Temperature Range | -50℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 30% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Cooling Rate | 5 ℃ / min |

Heating Rate | 5 ℃ / min |

Rated Force of Vibration | 1000kgf |

Frequency Range of Vibration | 2 to 4000 Hz |

Armature Diameter of shaker | φ240mm |

horizontal sliding table | 600*600 mm |

Power Amplifier | Digital power amplifier |

Head Expander | 600*600 mm |

Blower | 4Kw blower, including muffler. |

Cooling system | Mechanical compression refrigeration system |

Safety Device | Humidifier dry-combustion protection; over-temperature protection; over-current protection; Refrigerant high-pressure protection; Water shortage protection; Earth leakage protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Thermal Insulation | Polyurethane foam and insulation cotton |

Standard Configuration | Cable hole with plug; 2 shelves |

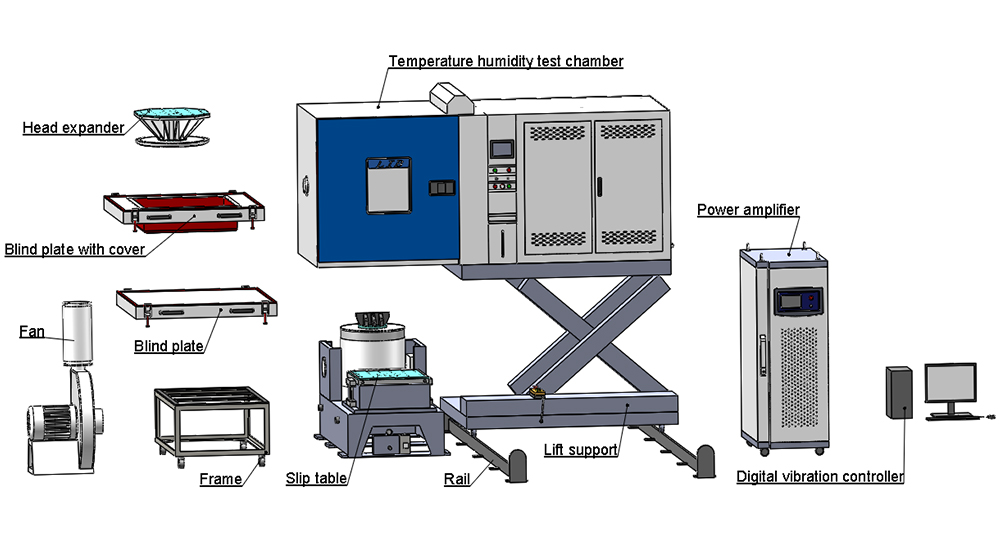

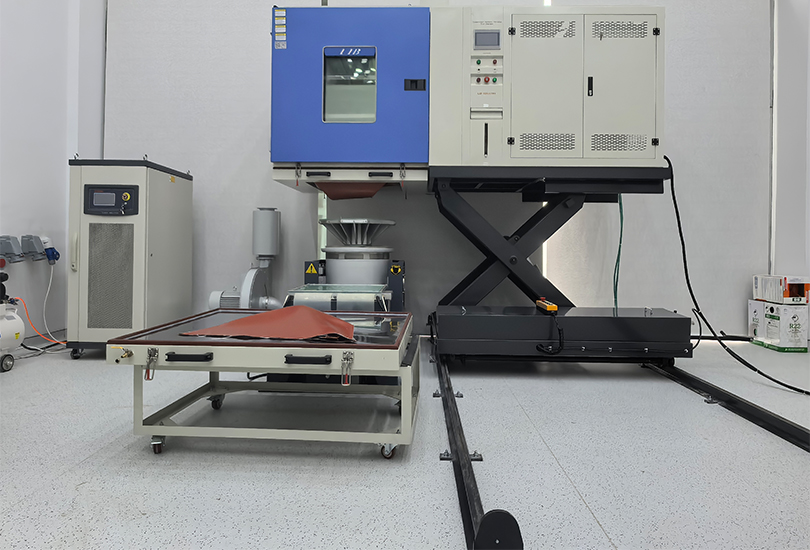

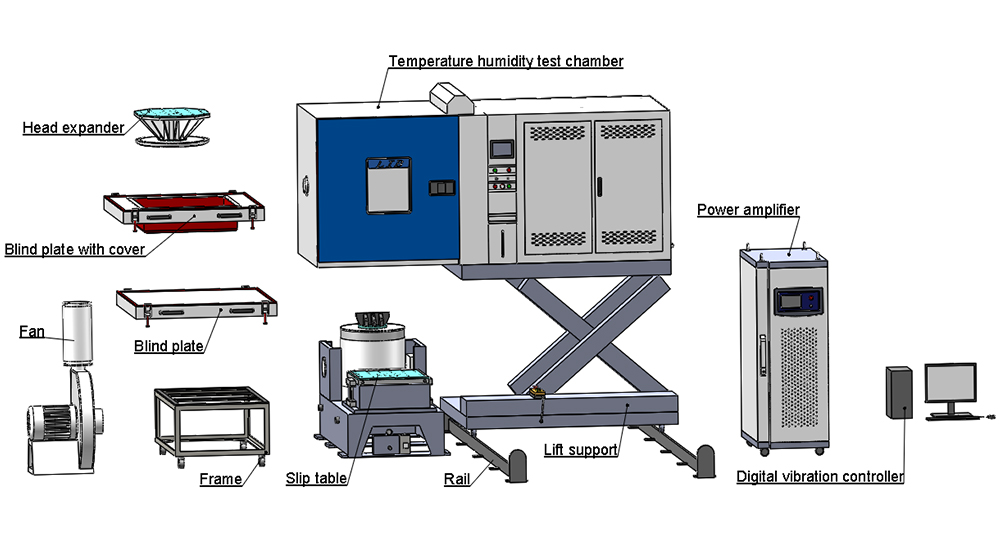

Configuration of Temperature Shaker Chamber

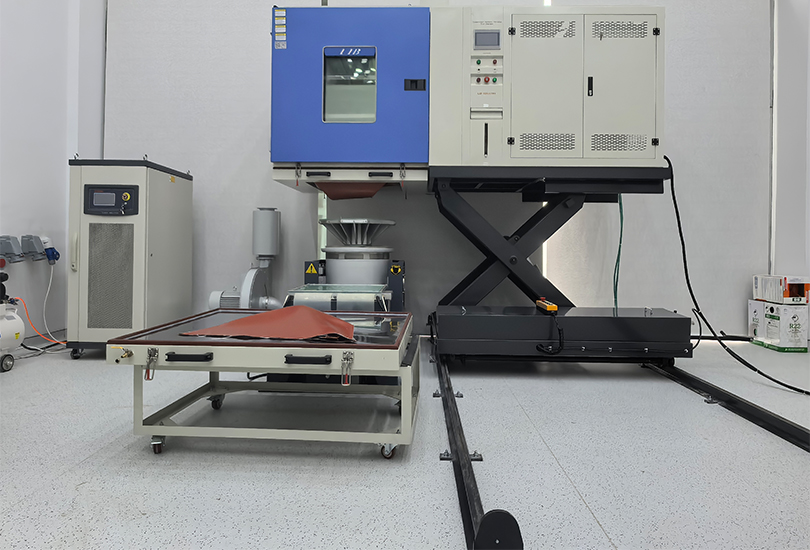

Temperature shaker chamber mainly includes a.temperature and humidity test chamber and b.vibration system.

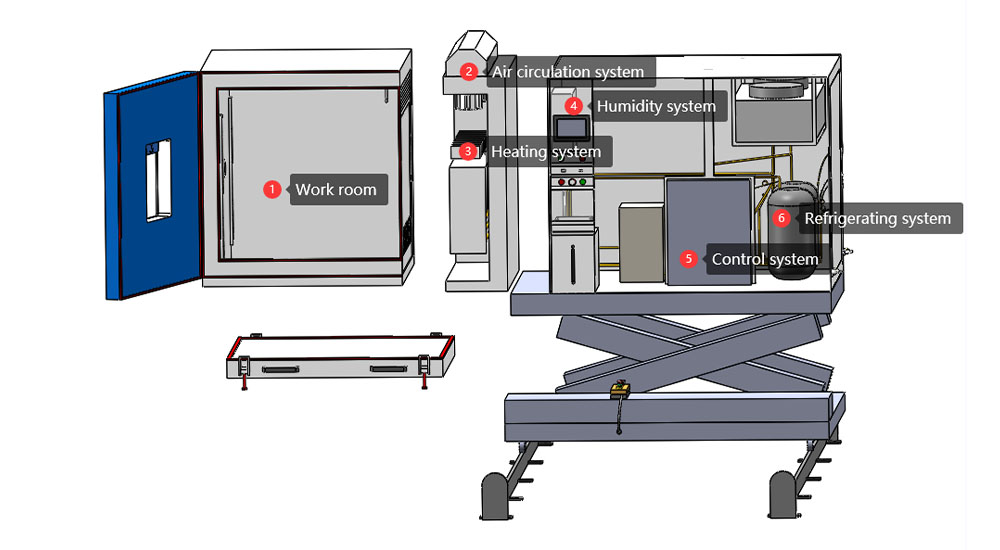

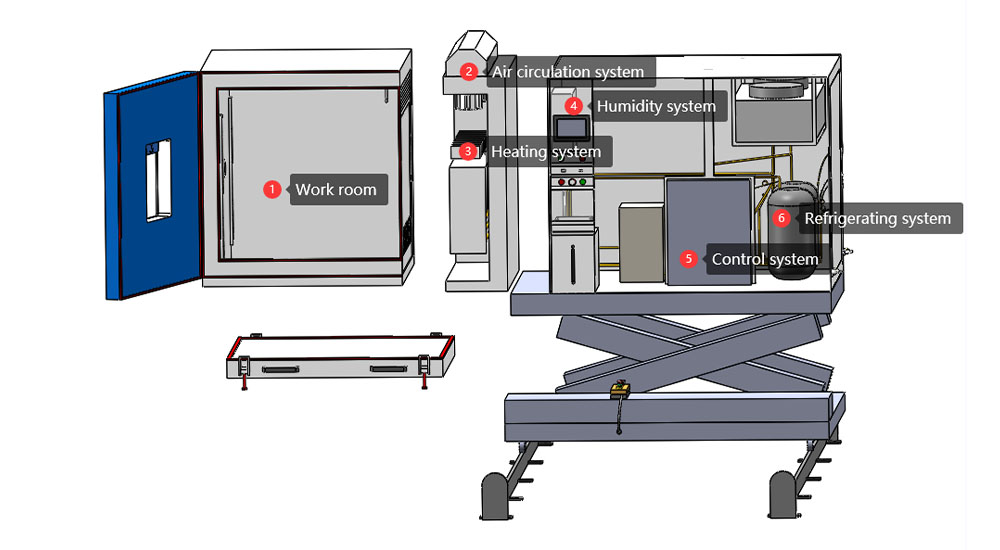

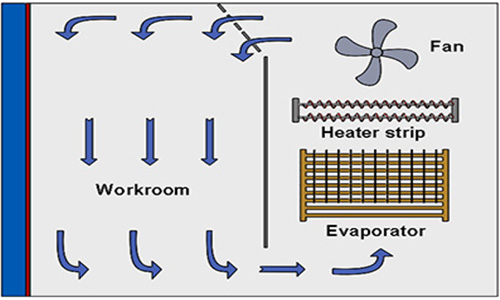

a. Temperature and Humidity Test Chamber

1. Workroom | The place where the test piece is tested. Double punched sample holder, removable to accommodate different sizes and shapes of test pieces. SUS 304 stainless steel plate, good corrosion resistance, easy to clean.

|  |

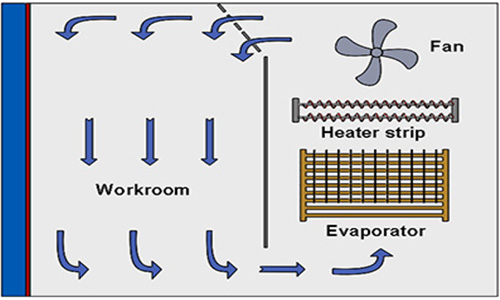

2. Air circulation system | Fans and ventilation ducts guide the airflow direction, improve the efficiency of air circulation, so that temperature and humidity can be evenly distributed in all parts of the chamber. Temperature Fluctuation is controlled at ± 0.5 ° C, Humidity Deviation is also within ± 2.5%RH. |  |

3. Heating system | High power electric heating wire, heating speed is fast and stable, can adjust the temperature range of -50℃ ~ +150 ℃, the temperature deviation is controlled at ±2℃. |  |

4. Humidity system | Evaporator humidification system, humidification stability, with the refrigeration system to adjust the humidity in the workroom. |  |

5. Control system | Simple and easy to operate control panel for setting temperature, humidity, vibration parameters and other experimental conditions. Data available for download. |  |

6. Refrigerating system | Including compressors, condensers, throttling devices and evaporators, using mechanical refrigeration, more stable and more efficient, in a short time can make the workroom temperature drop to the set temperature. |  |

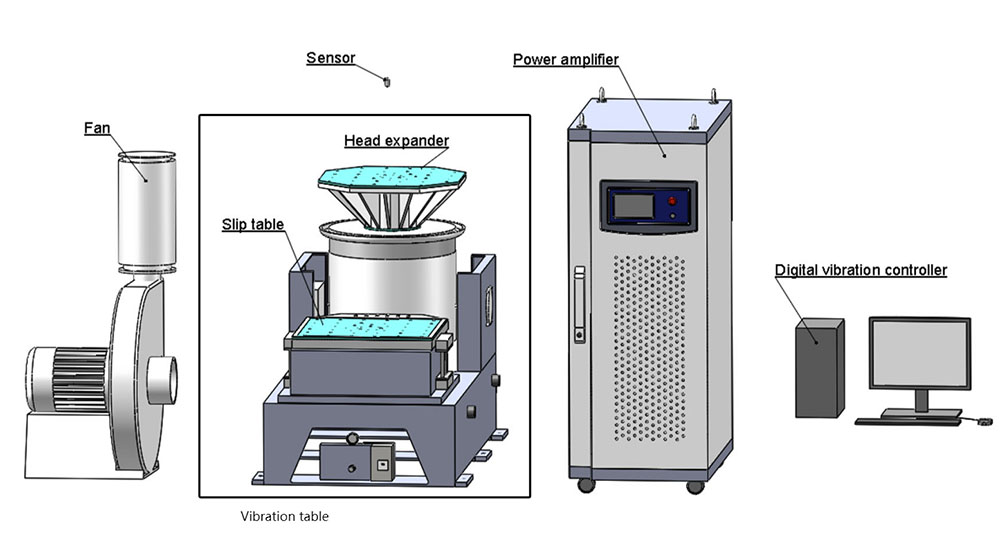

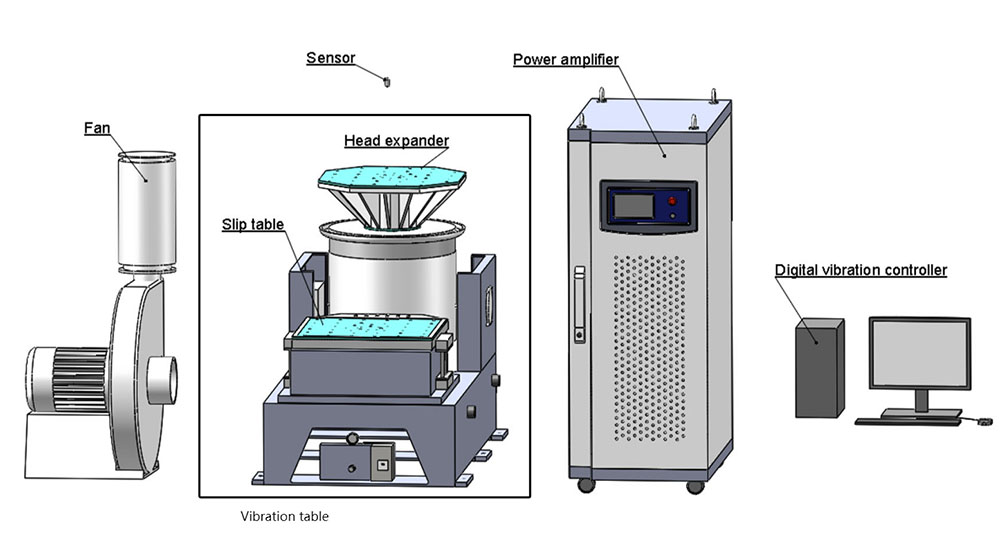

b. Vibration System

Vibration table | Provide vibration environment, simulate vibration in practical applications, such as bumps during transportation, vibration during equipment operation, etc. The vibration frequency range is 2-4000HZ, and the vibration direction includes vertical vibration and horizontal vibration.

|  |

Fan | Axial fan heat dissipation, help dissipate the heat generated during the operation of the vibration system. |  |

Power amplifer |

Receive the low-power signal from the signal source and amplify it into a signal with enough power to ensure that the vibration table can produce stable and accurate vibration.

|  |

Digital vibration controller |

Set and control vibration parameters, such as frequency, amplitude, vibration time, etc. Different vibration test programs can be edited and stored to meet diverse test needs.

|  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español