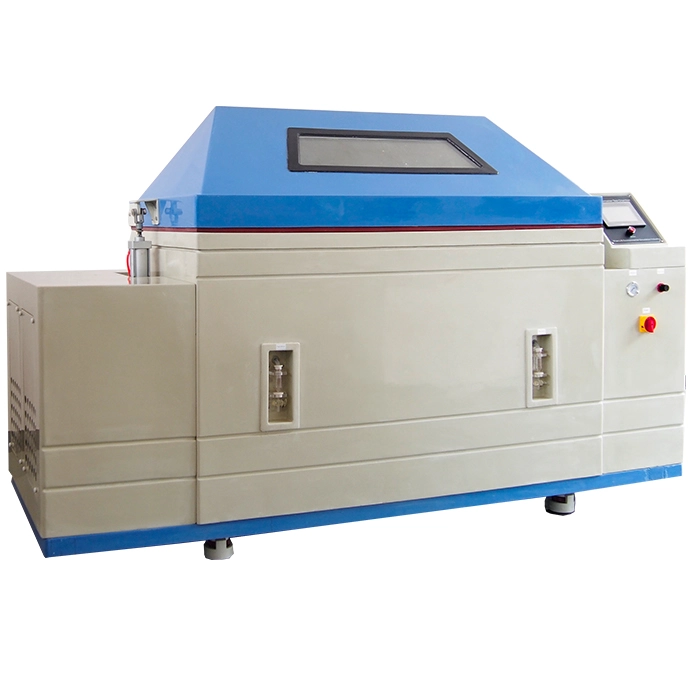

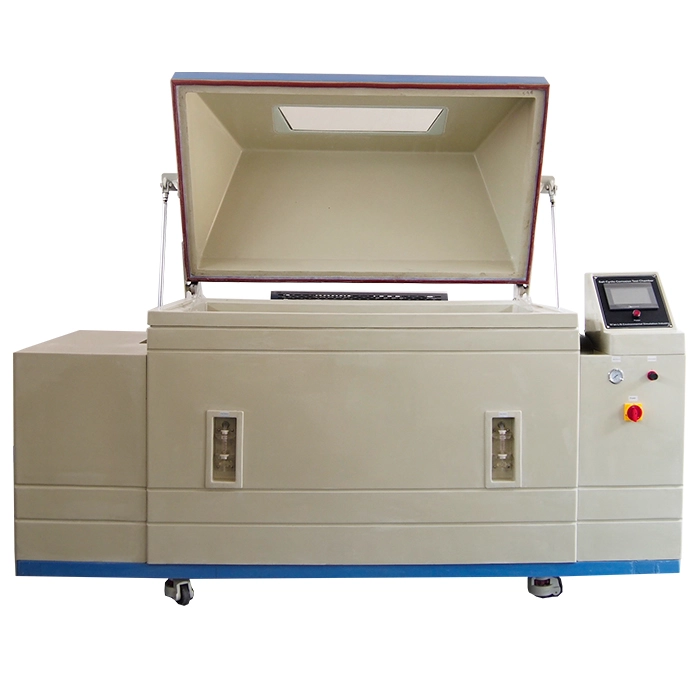

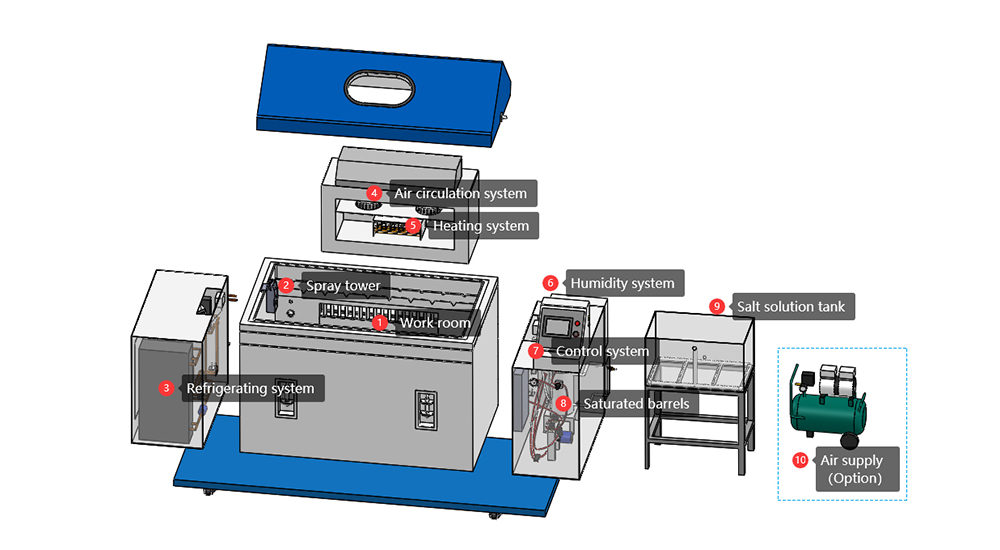

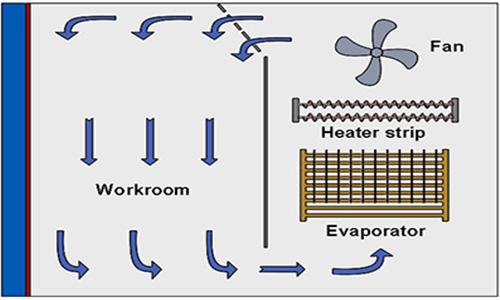

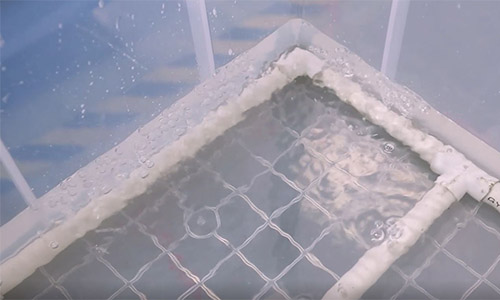

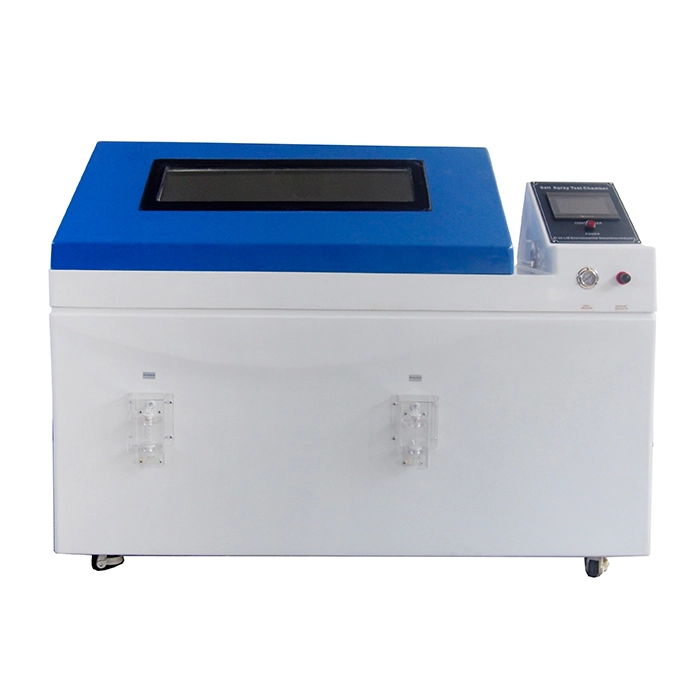

ASTM G85 salt spray chamber meets ASTM G85 standards and is used to evaluate corrosion resistance of metallic materials, organic and inorganic coatings. By simulating the salt spray environment and exposing the sample to a controlled salt spray environment determines the corrosion resistance of the material or coating.

Temperature range: +10℃ ~ +90℃, humidity range: 30% ~ 98%RH, salt spray deposition: 1 ~ 2ml/80cm²•h. Spray method: continuous, adjustable cycle.

Model: SC-010, SC-016, SC-020

Standard: ASTM B117, ISO 9227, ASTM G85, D17 2028, SAE J2334, ISO4611, ISO7253, IEC 60068-2-11, ASTM G85-02e1 Annex A1, DIN 50021, ASTM B368

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español