Features and Benefits of IP6X Test Machine

1. Highly sealed test chamber with rubber seal between the workshop and the door, and magnetic lock to prevent misoperation to ensure that dust does not leak into the external environment during the test.

2. Highly accurate simulation of the dust environment, the dust filtered by metal square holes with a wire diameter of 50μm and a screen size of 75μm. The airflow speed in the test chamber should be controlled within 2m/s.

3. In line with IP6X protection grade test standards, such as IEC 60529, ISO 20653, etc., it can also adjust the temperature,and has a vacuum function, which can be a more comprehensive evaluation of the comprehensive protection performance of the product.

4. Advanced automatic control system, which can realize the automatic control of the test process, including dust blowing, pumping, temperature regulation and other operations.

Specifications of IP6X Test Machine

Model | DI-800 | DI-1000 | DI-1500 | DI-2000 |

Internal Dimension (mm) | 800*1000*1000 | 1000*1000*1000 | 1000*1500*1000 | 1000*2000*1000 |

Overall Dimension (mm) | 1040*1450*1960 | 1330*1450*1960 | 1330*1950*1990 | 1330*2450*1990 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ |

Humidity Range | < 30% RH |

Normal Wire Diameter | 50um |

Nominal Width of a Gap Between wires | 75um |

Fight Time | 0 ~ 99H59M |

Blowing Time | 0 ~ 99H59M |

Specimen Power Outlet | Dust-proof socket 16A |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Safety Device | Over-temperature Protection; Over-current Protection; Earth Leakage Protection; Phase Sequence Protection |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Standard Configuration | Sample shelf, dust wiper, talcum powder(5kgs) |

Power | AC380V 50Hz |

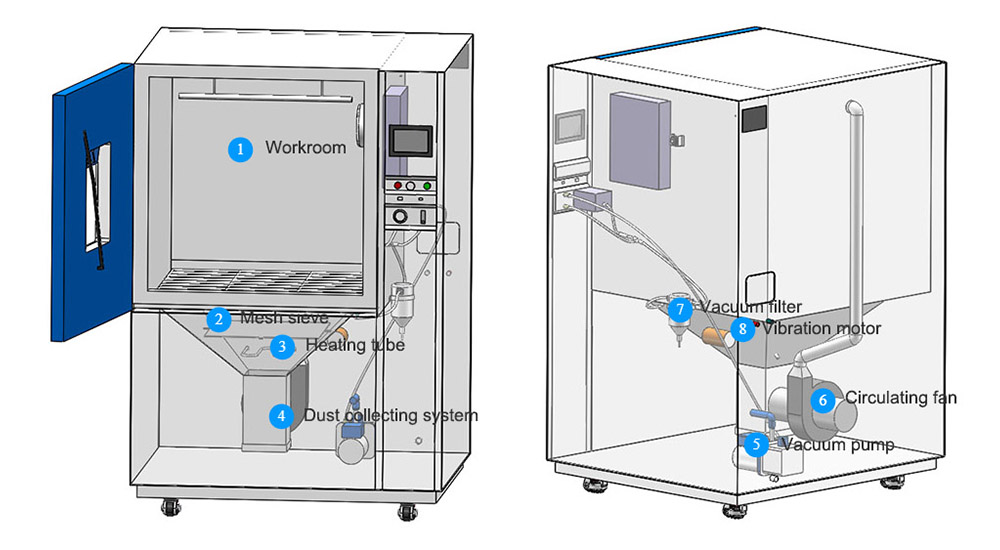

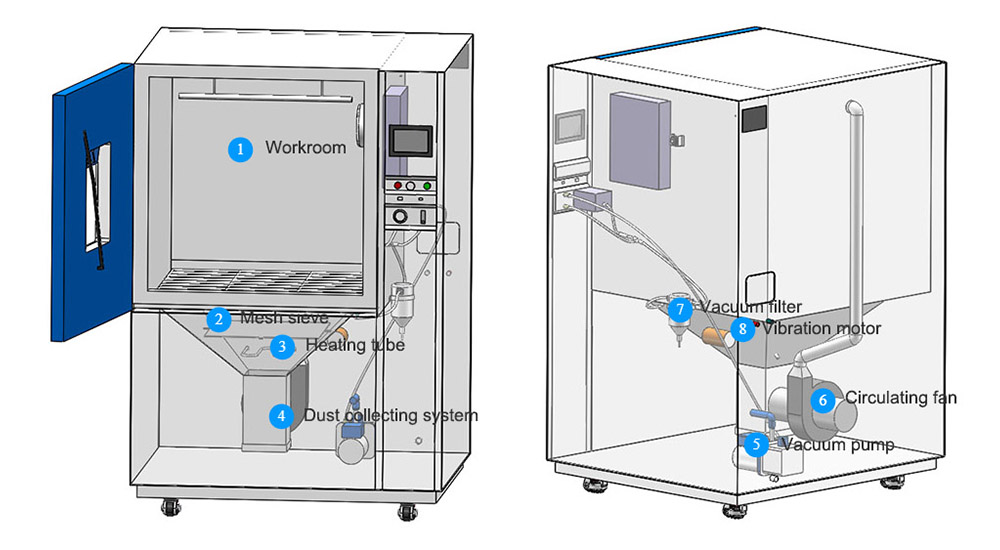

Configuration of IP6X Test Machine

① Workroom | SUS304 stainless steel light plate, good corrosion resistance and high temperature resistance, smooth surface, can reduce the adhesion of dust. Equipped with hanging sample holder. The lighting and observation window with wiper for the operator to observe the test process. The dust sent down from diffusion port on the workroom top is evenly diffused into the test chamber to form a top-down vertical airflow.

|  |

② Mesh sieve | Nominal diameter of dust is 50 μm. Prevent large particles from fall out the duct. |  |

③ Heating tube | Heating dust prevents dust agglomeration due to high humidity. |  |

④ Dust collecting system | Cone funnel: Located at the bottom of the workroom to collect and store dust Dust collection port: arranged at the bottom of the cone funnel and connected with the dust extraction port. During the test, dust is inhaled into the circulation system through the collection port.

|  |

⑤ Vacuum pump | As the power source of the vacuum system, it provides the required vacuum degree for the entire system. |  |

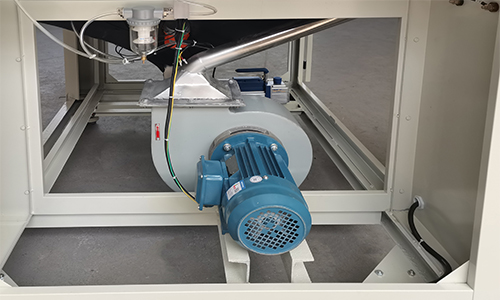

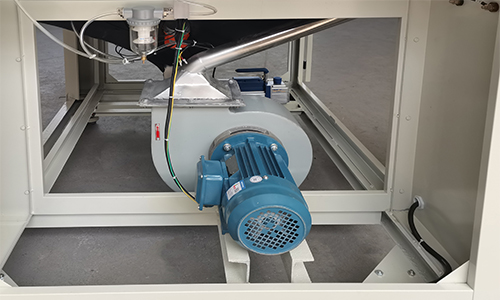

⑥ Circulating fan | High-pressure turbine circulator, pumping the dust collected at the bottom to the top of the inner tank. |  |

⑦ Vacuum filter | When the vacuum pump is working, the vacuum filter can filter the dust in the extracted gas to avoid the dust entering the vacuum pump. |  |

⑧ Vibration motor | Shake off excess dust stuck to the workroom and cone. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español