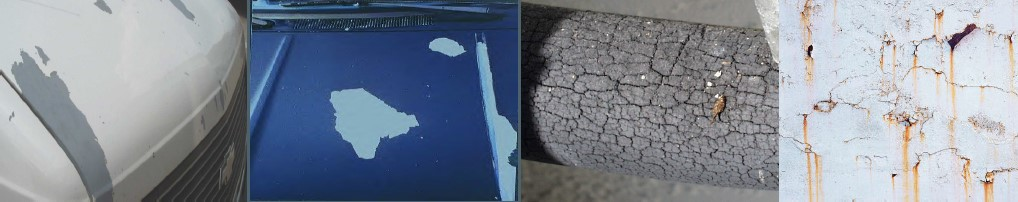

Every year, the economic loss caused by aging is hundreds of millions. Aging often causes changes in the physical properties of textiles, coatings, plastics and some other organic matter, mainly in discoloration, loss of light, strength decline, cracking, peeling, pulverization and oxidation. We know that sunlight, especially short-wavelength ultraviolet light, high temperatures, rain, dew, and moisture in the form of high humidity are major contributors to the above damage.

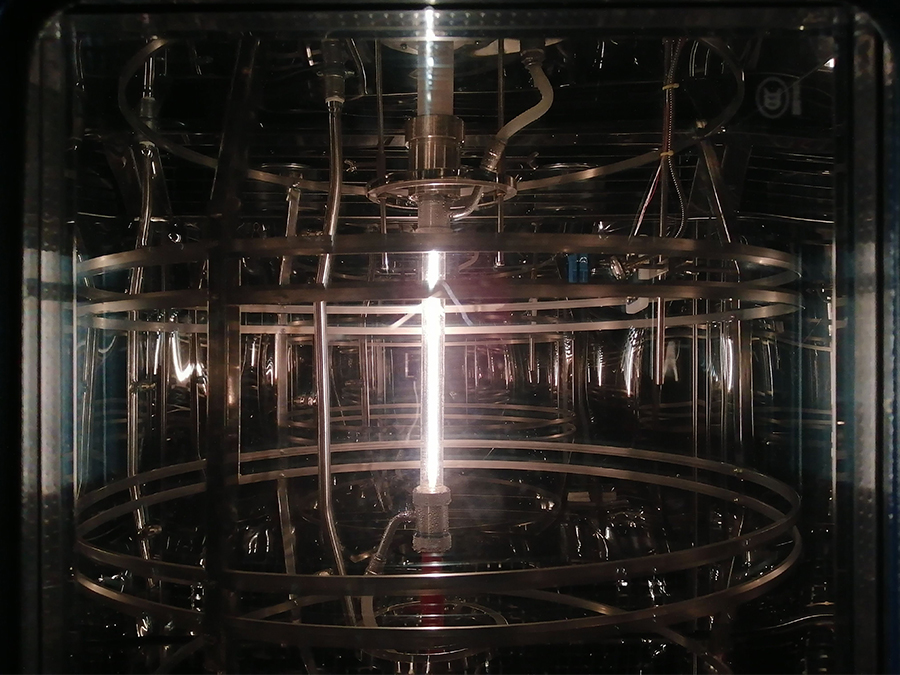

The weatherometer is the xenon lamp aging test chamber, which can also be called xenon arc lamp aging test equipment, xenon lamp weatherometer, etc., which can simulate the xenon arc lamp of the full sunlight spectrum to reproduce the destructive light waves existing in different environments, and provide corresponding environmental simulation and accelerated testing for scientific research, product development and quality control.

Weatherometer is a kind of equipment that simulates the solar radiation in the natural environment, mainly through the high intensity ultraviolet, visible light and infrared light emitted by xenon lamp to accelerate the aging process of products. It can simulate the aging effect of products in the natural environment for several years or even decades in a short time, and provide enterprises with fast and accurate product aging test data.

The working principle of weatherometer mainly includes the following aspects:

Xenon lamps are high-intensity gas discharge lamps that emit a spectrum similar to that of sunlight. The xenon lamp in the test chamber generates ultraviolet, visible and infrared rays through high voltage discharge, which can penetrate the surface of the product, affect the material and structure inside the product, and accelerate the aging process of the product.

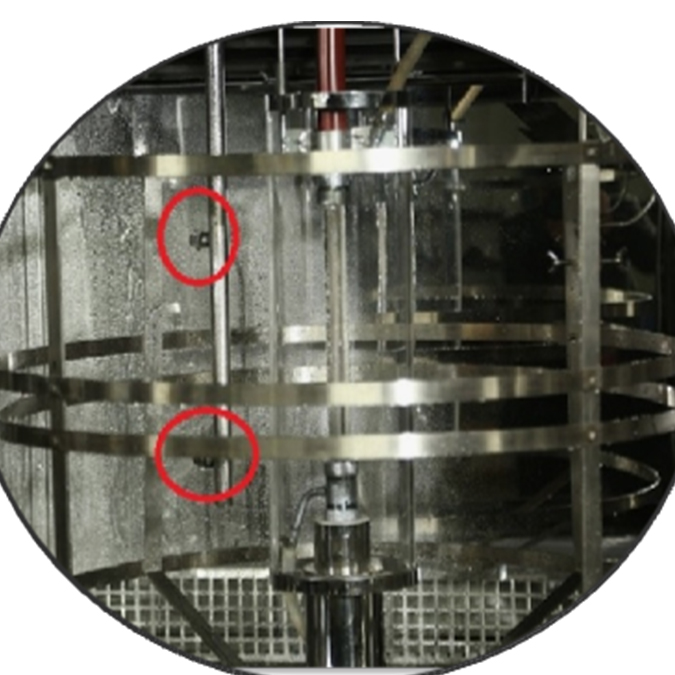

weatherometer can accurately control the temperature in the test chamber and simulate different ambient temperature conditions. The change of temperature will affect the material properties and aging rate of the product, so accurate temperature control is an important factor to ensure the accuracy of the experimental results.

In addition to temperature control, weatherometer can also control the humidity inside the test chamber to simulate different humidity environmental conditions. The change of humidity will affect the corrosion and aging rate of the product, so humidity control is also one of the important functions of the weatherometer.

Some weatherometers are also equipped with spray systems that simulate wet conditions such as rain and dew in natural environments. The spray system can spray the product to test the water resistance and corrosion resistance of the product.

This question is one of the most frequently asked, but also one of the most difficult to answer, and there is no standard or paper that specifies how long accelerated aging in the laboratory is equivalent to one year in the natural environment or gives a clear formula.

The main reason is that there are too many factors that change natural conditions, and many factors that cause product aging such as light intensity, light time, temperature, humidity, rainfall and pollutants, etc., the laboratory can not simulate all of them.

Therefore, most of the current standards do not give testing time, and the time is the result of multi-party negotiation. Some standards have a given time. One is the result of comparing laboratory data with data that can be used over time, such as most automotive standards. The other is to consider only a single factor, such as: only consider the total amount of light in a region, with irradiance inverse derivation, the most typical standard is:

EN 12608-2003 Unplasticized polyvinyl chloride (PVC-U) profiles for doors and Windows. Classification, requirements and test methods, the calculation formula is as follows:

Aging time = total annual solar irradiation × number of years ×60% ×67%÷550÷3600

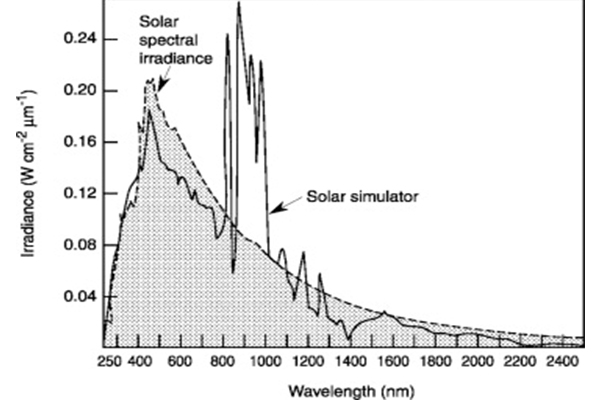

---- Annual total solar irradiance: the sunlight absorbed by the ground in the wavelength range of 300 ~ 2450nm

Total annual irradiation, J/m2;

----60% : Irradiation in the wavelength range of 300 ~ 800nm accounted for the percentage of the total irradiation

To absorb this range of light causes aging degradation;

----67% : temperature correction factor. Due to natural aging, the average temperature in other seasons except summer

Relatively low;

----550: The spectral wavelength of the weatherometer emitted when the Boro/Boro filter combination is used

Around 300 ~ 800nm irradiation amount, W/m2;

----3600:1 hour =3600 seconds

A. Temperate climate M doors and windows (5 years of outdoor exposure requirements)

Total annual irradiation: 4×109J/m2

Aging time =4×109 ×5×60% ×67%÷550÷3600=4061h

Standard requirement: 4000h

B. Class S doors and windows in tropical climate (5 years of outdoor exposure requirement)

Total annual irradiation: 6×109J/m2

Aging time =6×109 ×5×60% ×67%÷550÷3600=6091h

Standard requirement: 6000h

Compared with the traditional aging test method, because the natural aging test takes several years to determine the aging result, the time cost is too high for the general enterprise, especially in this competitive era, the product development cycle is very short, if the test cycle of a new product takes several years, the product is not competitive at all.

At the same time, due to the ever-changing climatic conditions around the world, the same measured material may get very different aging results, and the repeatability and reproducibility of the experimental results are not very good. Therefore, people tend to use laboratory equipment to artificially accelerate aging, which can not only shorten the test cycle, good repeatability, can be used for quality control, material stability testing and rapid comparative screening tests of materials.

In addition, this method has a wide range of applications for aging testing of various materials and products, including plastics, rubber, coatings, textiles, electronic products, etc., because it is only used indoors, can not be restricted by natural conditions, only consider the influence of human factors, easy to use, high controllability.

With the continuous progress of science and technology and the continuous growth of market demand, xenon lamp test boxes are also constantly developing and innovating. In the future, the weatherometer will be more intelligent, multi-functional, miniaturized, energy-saving and environmental protection, and provide more high-quality product quality testing services for enterprises. Let us look forward to the weatherometer in the future development, continue to play its magic, and make greater contributions to the quality and reliability of products.